Stereo Microscope QA: Surface Defect Grading & Rework Decisions

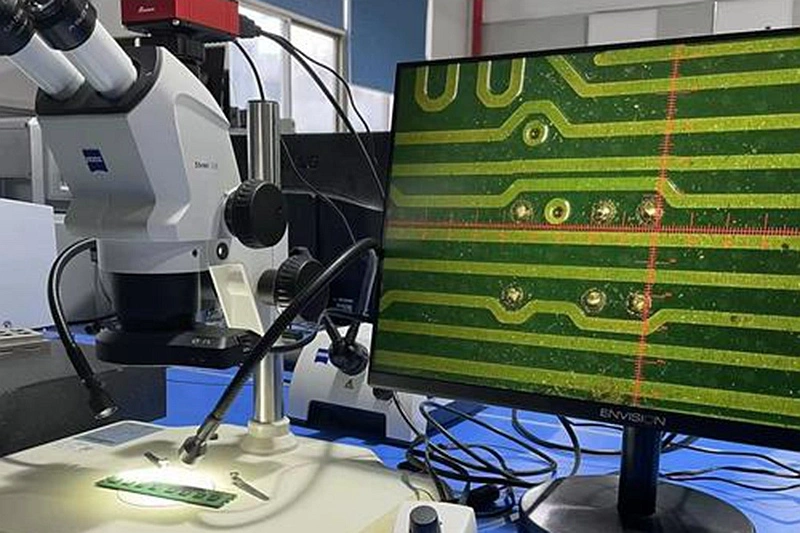

Introduction: Beyond the Naked Eye – How Stereo Microscopes Digitalize and Systematize Surface Quality Control

In metal additive manufacturing, surface quality is not just about appearance; it is a critical factor that affects part functionality and service life. As quality engineers at Neway, we fully understand the diversity and complexity of surface defects on 3D-printed parts, ranging from powder adhesion and support residues to microcracks. Relying solely on visual inspection introduces subjectivity and inconsistency. In response to these challenges, we have implemented a stereo microscope inspection system. This technology elevates surface quality control from experience-based subjective judgment to data-driven objective evaluation, providing a scientific basis for defect grading and rework decisions.

What Is Stereo-Microscope-Based Surface Quality Inspection?

Technical Advantages: 3D Depth of Field and Stereo Vision

Stereo microscopes are fundamentally different from traditional optical microscopes or simple magnifiers. Their core advantage lies in providing true three-dimensional images with real depth perception. During our daily inspections, this stereoscopic capability enables engineers to accurately assess the depth, morphology, and actual severity of defects. For example, when examining support-removal marks, we can not only observe surface traces but also clearly determine the depth of depressions and the extent of affected surrounding material—crucial information that 2D imaging simply cannot offer.

Neway’s Standardized Inspection Process

We have established a comprehensive standardized workflow to ensure consistency and comparability of results. First, we use LED ring lighting with fixed parameters to maintain identical illumination conditions for every inspection. A predefined magnification sequence (20x, 50x, 100x) is applied, with appropriate levels selected based on defect type. Engineers follow a defined scanning path to systematically examine all critical and general surfaces, ensuring no area is overlooked. Finally, discovered defects are identified, categorized, and documented according to our internal evaluation criteria.

How Neway Integrates Stereo Microscopes into Surface QA and Rework Decision-Making

Defect Identification and Precise Classification

Under a stereo microscope, different surface defects exhibit distinct morphological characteristics. We can accurately distinguish powder adhesion from scratches, and differentiate support contact marks from thermal cracks. For instance, partially sintered powder particles usually appear as randomly distributed spherical bumps, whereas support residues exhibit regular geometric patterns and directional distribution. This level of precise classification provides a robust foundation for subsequent decisions.

Establishing Defect Grading Criteria: From Acceptable to Reject

Drawing on years of experience and empirical data, we have developed a scientific grading system for defects. It comprehensively considers defect size, density, location, and the part’s end-use conditions. Defects are categorized into three levels: acceptable, rework required, and scrapped. For example, minor powder adhesion in non-critical areas may be classified as acceptable, while the same type of defect on a sealing surface could be flagged for rework.

Guiding Precise Rework: Determining the Optimal Post-Processing Method

Stereo microscope findings directly guide our choice of post-processing methods. For light powder adhesion, we may recommend sandblasting alone; for deeper support scars, polishing or localized CNC finishing may be necessary. This diagnosis-driven approach ensures optimal repair effectiveness while minimizing cost and avoiding unnecessary over-processing.

Typical AM Surface Defects Under the Microscope and Their Grading

Powder Adhesion and Unsintered Particles

Under the stereo microscope, powder adhesion appears as randomly distributed spherical particles, ranging in size from tens to hundreds of micrometers. We classify these conditions into three levels based on the number of particles per unit area and their size: minor (<5 particles/cm²), moderate (5–15 particles/cm²), and severe (>15 particles/cm²). This quantitative approach ensures consistent evaluation.

Support Contact Marks and Scars

Support residue defects exhibit regular geometric patterns under magnification and often feature localized tearing or depressions. We grade them by depth and sharpness: shallow marks (depth < 50 μm) are generally acceptable, whereas deep, sharp scars (depth > 100 μm) typically require treatment, as they can act as stress concentrators and initiation sites for fatigue cracks.

Scratches, Layer Lines, and Balling Phenomena

Different 3D printing processes generate distinctive surface features. Scratches appear as linear grooves, layer lines as periodic step-like patterns, and balling as irregular metallic spherical protrusions. We grade these features according to their prominence and impact on part function, providing targeted feedback for process optimization.

Value of Data-Driven Rework Decisions for Core Manufacturing Processes

The stereo microscope inspection system significantly enhances our manufacturing efficiency and robustness of quality. First, with accurate defect grading, we avoid unnecessary rework, resulting in a reduction of approximately 15% in post-processing costs. Second, by deeply understanding defect morphology, we select more targeted rework methods, increasing rework success rates by over 30%. Most importantly, the visual quality records we build for each part fully align with the stringent traceability requirements of industries such as aerospace.

Synergy Between Stereo Microscopes and Other Inspection Technologies

As a Front-Line Tool Before Internal Defect Inspection

In our inspection workflow, stereo microscope evaluation is often used as a preliminary step before industrial CT and X-ray testing. By first ruling out surface-related issues, we can focus internal inspection resources more efficiently, ensuring comprehensive yet streamlined defect analysis.

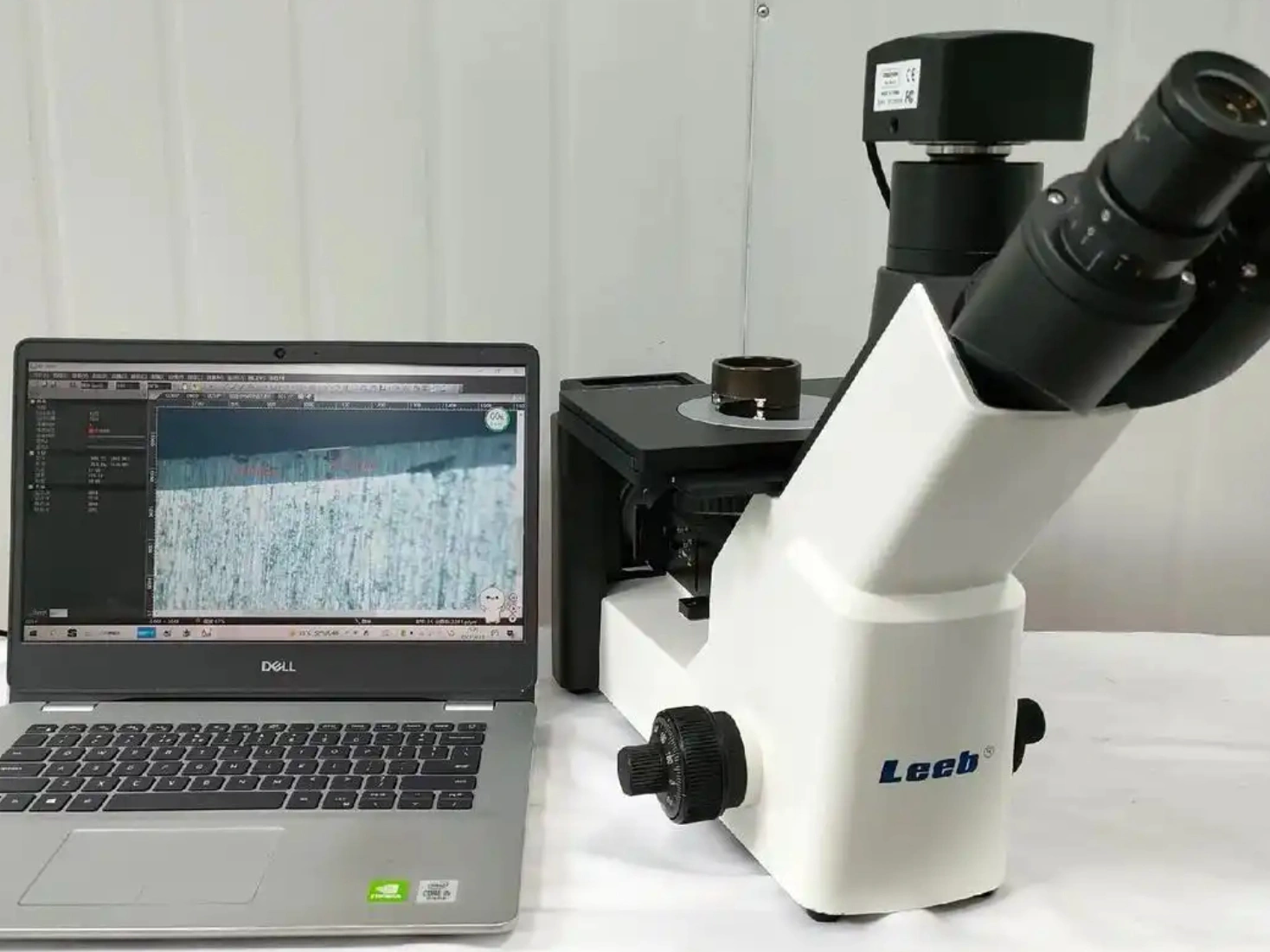

Correlation with Material Analysis

When suspected cracks or anomalies are detected on the surface, the stereo microscope plays a critical role in localization. We precisely mark suspect regions under the microscope and then prepare cross-sectional samples for metallographic analysis to examine the depth of cracks, propagation paths, and root causes.

Complementing Dimensional Control

Stereo microscopes complement 3D scanning within our quality framework. While 3D scanning ensures macro-level dimensional conformity, stereo microscopes focus on micro-level surface integrity. Together, they deliver comprehensive quality control from the overall geometry down to the smallest surface features.

Case Study: How Stereo Microscope Inspection Salvaged a Batch of High-Value Inconel 718 Turbine Blades

In an aero-engine project, a batch of Inconel 718 turbine blades produced via powder bed fusion underwent heat treatment and entered final inspection. Visual inspection revealed faint marks on the pressure side of the airfoils, initially suggesting the need for rework.

We immediately conducted a detailed evaluation using a stereo microscope. At 50x magnification, the marks were clearly identified as dense but very shallow support-removal scars, with depths measured between 20 and 30 μm, and no observable damage to the base material was observed. Moreover, these marks were located in non-primary load-bearing regions. According to our internal acceptance criteria, such defects were within allowable limits.

Based on this objective analysis, we concluded that "no rework is required, parts are acceptable." This decision not only saved the customer additional sandblasting costs but also avoided potential negative impacts on blade profile accuracy. This case clearly demonstrates the critical value of scientific inspection in quality decision-making.

Conclusion: Excellence in Every Detail – Guarding Surface Quality with Scientific Precision

The adoption of stereo microscope inspection marks a new level of capability in Neway’s surface quality control. We have transformed traditionally subjective assessments of "surface finish" into objective, quantifiable, and traceable data. Throughout each project, we focus not only on obvious imperfections but also on subtle indicators of underlying quality risks. We believe that true manufacturing excellence is reflected in uncompromising attention to every detail. We sincerely invite customers with stringent requirements on appearance and surface integrity to experience our meticulous quality inspection services and to pursue perfection in manufacturing quality together with us.