X-Ray Inspection: Rapid Internal Defect Screening for AM Parts

Introduction: Seeing the Unseen – How X-Ray Inspection Gives 3D Printed Parts "X-Ray Vision"

In the field of metal additive manufacturing, internal quality often determines the reliability of the final product. As quality engineers at Neway, we fully understand the hidden nature and potential severity of internal defects—porosity, lack of fusion, and other imperfections concealed within the part act like time bombs threatening product safety. In high-demand sectors such as aerospace and medical devices, traditional inspection methods are often powerless against such internal flaws. In response to these challenges, we have adopted industrial X-ray inspection technology, an advanced non-destructive testing method that provides a revolutionary solution for ensuring the quality of our critical components.

Introduction to Industrial X-Ray Inspection Technology

Working Principle: Penetration, Absorption, and Imaging

Industrial X-ray inspection is based on the attenuation of X-rays as they pass through materials. When X-rays penetrate the test object, internal structures of different densities absorb the radiation to varying degrees. High-density areas (such as the metal matrix) absorb more X-rays, while defect regions (such as pores and cracks) absorb less. This difference creates contrast on the detector, forming an image that clearly reveals the internal structure of the part. Our inspection systems utilize micro-focus X-ray sources, achieving a resolution of 5 μm or less, ensuring that even the most minute defects cannot escape detection.

2D X-Ray vs. 3D Industrial CT

In practice, we employ two primary X-ray inspection modes according to different requirements. 2D X-ray inspection offers fast and cost-effective screening of internal structures, making it ideal for batch inspection of relatively simple parts. For components with complex internal geometries, we use 3D industrial CT scanning. By acquiring hundreds of 2D projection images from different angles, CT reconstructs a 3D model of the part, enabling both defect detection and precise three-dimensional localization and quantitative analysis. This provides comprehensive data support for evaluating the internal structure.

How Neway Integrates X-Ray Inspection into the AM Quality Control Process

Post-Print Rapid Screening: A Replacement for Destructive Sectioning

In traditional manufacturing, evaluating internal quality often relies on destructive sectioning, which is costly and inherently limited by the need for sampling. In our quality control system, X-ray inspection fully replaces this destructive approach. Especially for parts produced via powder bed fusion, we perform 100% X-ray screening on first articles and critical parts, enabling a comprehensive assessment of process stability without damaging the parts. This non-destructive inspection approach significantly reduces cost and time while preserving the integrity and completeness of quality evaluation.

Process Development and Optimization: Locating the Root Cause of Defects

X-ray inspection plays a crucial role during process development. By analyzing defect morphology, location, and distribution, we can accurately trace issues back to 3D printing process parameters. For example, a high concentration of spherical pores often points to problems with shielding gas or powder quality; irregular lack-of-fusion defects are typically associated with improper laser power or scan strategies. These insights provide clear guidance for process optimization.

Incoming Inspection of Supplies: Ensuring Metal Powder Quality

Beyond finished parts, X-ray inspection is also used in raw material quality control. We perform sample inspections on each batch of incoming metal powders, using X-ray imaging to detect any high-density foreign inclusions. Such inclusions may originate from raw materials or contamination during powder production, and if left undetected, can become stress concentrators in printed parts, significantly affecting fatigue performance. This source-level control forms a solid foundation for our subsequent printing processes.

Applications of X-Ray Inspection in Typical AM Defect Screening

Identification of Porosity and Lack-of-Fusion Defects

Porosity and lack of fusion are among the most common internal defects in additive manufacturing. With X-ray inspection, we can clearly distinguish between spherical pores caused by insufficient shielding gas or powder contamination and irregular lack-of-fusion defects resulting from suboptimal scan strategies or energy input. Our systems can detect defects as small as 20 μm, ensuring that even subtle process deviations are captured in a timely manner.

Detection of Cracks and Inclusions

For parts that have undergone heat treatment, X-ray inspection effectively detects micro-cracks caused by thermal stresses. These cracks appear as fine, elongated dark lines on X-ray images and, due to their orientation and location, often require multi-angle imaging to avoid missed detection. At the same time, we can identify foreign inclusions in the material, providing critical information for optimizing post-processing and upstream material control.

Inspection of Residual Supports and Clogged Internal Channels

For parts with complex internal channels, X-ray inspection is the most effective method to validate internal integrity. It allows us to clearly confirm whether internal supports have been completely removed and whether cooling channels or flow paths are free from blockages. This capability is especially critical for aerospace engine components and medical implants, where the reliability of internal passages is vital.

"Fast Screening" – Core Value for AM Production

100% Non-Destructive Inspection, Enabling Full Quality Visibility

The greatest advantage of X-ray inspection lies in its non-destructive nature. We can perform internal quality verification on every critical part shipped, completely overcoming the limitations of traditional sampling inspection. This comprehensive assurance is particularly suitable for aerospace and medical device applications with extremely high reliability requirements, providing our customers with unmatched confidence in product quality.

Accelerated R&D Iterations and Lower Development Costs

During new product development, X-ray inspection significantly shortens process tuning cycles. We can obtain detailed feedback on internal quality within hours, without waiting for destructive test results. This rapid feedback mechanism allows our R&D teams to optimize process parameters more quickly, substantially reducing trial-and-error time and development costs.

Strengthening Customer Confidence with Objective Evidence

Each X-ray inspection report includes clear images and detailed analytical data, providing objective evidence of internal quality. In cases of quality disputes or failure analysis, these records become crucial references for tracing root causes, greatly enhancing customer trust in our products.

Synergy Between X-Ray Inspection and Other Quality Inspection Technologies

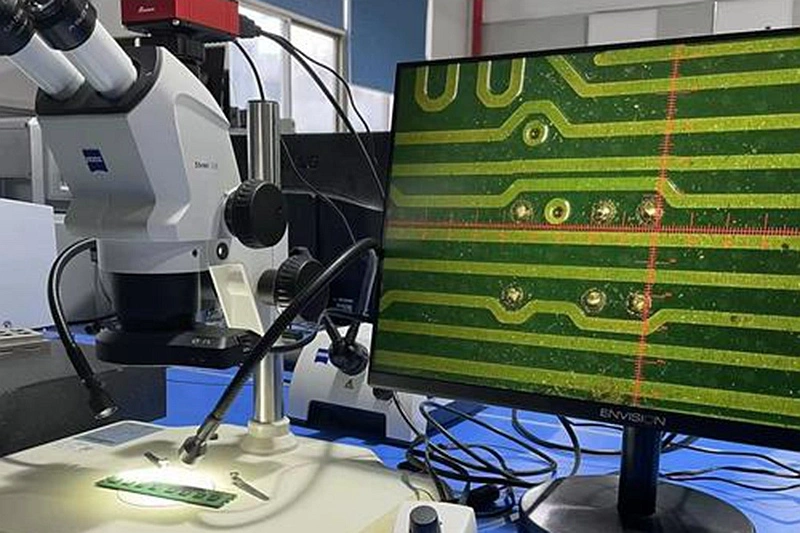

Complementarity with Surface Inspection

Within our quality system, X-ray inspection works hand-in-hand with surface inspection technologies. While X-rays reveal internal defects, stereo microscopes and other surface analysis tools evaluate external appearance and surface integrity. The combination of these methods delivers comprehensive quality assessment from the surface to the core, ensuring that every part shipped meets the highest standards.

Correlation with Mechanical Testing

By correlating X-ray inspection results with mechanical testing data, we have developed quantitative models that link defect characteristics to performance metrics. This analytical approach enables us to understand how different defect types, sizes, and locations impact part performance, providing a solid foundation for defining more precise and scientific quality standards.

Pre-Screening for In-Depth Industrial CT Analysis

In our practical workflows, we adopt a tiered inspection strategy. We first use 2D X-ray for rapid, low-cost preliminary screening. Any suspicious parts identified are then examined using 3D industrial CT for in-depth analysis. This approach ensures comprehensive coverage while optimizing resource allocation, achieving the best balance between efficiency and inspection depth.

Application Case: How X-Ray Inspection Prevented Potential Failure of a Batch of Inconel 718 Blades

In one of our recent aerospace projects, a batch of Inconel 718 turbine blades for aircraft engines underwent quality inspection after heat treatment. Following our standard procedure, we performed X-ray sampling inspection on the batch. During this process, our engineers identified fine, linearly distributed anomalies at the blade root. These indications retained consistent features across multiple viewing angles and were initially suspected to be micro-cracks.

We immediately activated our emergency response protocol, quarantined the entire batch, and expanded inspection coverage. Suspect blades were sectioned for further examination, and metallographic analysis confirmed that the anomalies were indeed stress corrosion cracks caused by improper heat treatment. Further investigation revealed a non-uniform distribution of furnace temperatures as the root cause. This timely detection prevented the delivery of defective parts with potential safety hazards, averting a serious quality incident.

Conclusion: Equipping Quality with "X-Ray Vision" to Eliminate Hidden Internal Defects

The application of X-ray inspection technology has enabled our quality assurance system to evolve from focusing solely on “surface” to fully understanding the “interior.” This technology not only uncovers defects that traditional methods fail to detect, but more importantly, provides solid, data-driven insights for process improvement and quality enhancement. At Neway, we believe that only through advanced inspection technologies can we truly realize a manufacturing philosophy of “visible quality and controllable processes.” We are committed to delivering above-standard, data-driven quality inspection services, ensuring that every part leaving our facility can withstand the most rigorous scrutiny.

Frequently Asked Questions

What is the minimum defect size that X-ray inspection can detect?

How long does it take to inspect a typical part (e.g., 100 mm x 100 mm x 100 mm)?

Does X-ray inspection pose health risks to operators? What safety measures are in place?

Is this inspection method applicable to all 3D printing materials, including plastics and ceramics?