SEM/EDS: Failure Analysis & Contamination Root Cause for AM

Introduction: Tracking the Culprits in the Microscopic World – How SEM/EDS Solves 3D Printing Failure and Contamination Puzzles

In the field of metal additive manufacturing, sudden part failures or unexplained performance fluctuations are often unexpected and disruptive. As failure analysis engineers at Neway, we understand that the root causes of these problems often lie in the microscopic world, beyond the naked eye's reach. A micron-sized inclusion, a nano-scale crack, or an unexpected trace of elemental contamination can be enough to cause complete functional failure of a part. To address these challenges, we rely on the powerful combination of Scanning Electron Microscopy (SEM) and Energy-Dispersive Spectroscopy (EDS). Like detectives, we search for evidence at the micro and nano scales, providing conclusive root-cause explanations for every failure case.

Overview of SEM/EDS Technology: Simultaneous Insight into Morphology and Composition

Scanning Electron Microscopy: Ultra-High-Resolution Imaging Beyond Optical Limits

SEM uses a focused electron beam to scan across the sample surface, constructing images by detecting emitted secondary electrons and backscattered electrons. Compared to conventional optical microscopes, SEM offers significantly higher resolution and depth of field, clearly revealing fracture morphology, crack propagation paths, pore structures, and other microfeatures. In our daily analyses, SEM can easily resolve details down to 0.1 micrometers, providing unprecedented visual evidence for understanding material failure mechanisms.

Energy Dispersive Spectroscopy: Giving Micro-Features a "Chemical ID"

EDS is a crucial complementary technique to SEM. By detecting characteristic X-rays generated when the electron beam interacts with the sample, EDS provides qualitative and semi-quantitative analysis of the elemental composition in the observed region. Whenever we identify abnormal features under SEM, EDS can immediately reveal their elemental makeup. Whether it is foreign particles, segregation, or surface contamination, EDS provides these micro-features with an accurate "chemical identity card."

How Neway Uses SEM/EDS for AM Failure Analysis and Contamination Tracing

Fractography: Decoding the Part’s "Last Moment"

A fracture surface is the "black box" that records the entire failure process of a part. By examining fracture features with SEM, we can accurately determine the failure mode. Ductile fracture is characterized by dimples, brittle fracture by cleavage facets, and fatigue fracture by distinct beach marks and striations. With EDS, we can further analyze the crack initiation zone to identify possible stress concentrators, such as inclusions, contamination, or other micro-defects.

Contamination Source Identification: Tracing Back from the Symptoms to the Root

Throughout the additive manufacturing workflow, contamination can be introduced at multiple stages. When abnormal performance is detected, EDS is used to compare the elemental composition of suspicious regions against that of the base material, helping us pinpoint the contamination source. It may originate from cross-contamination of metal powders, wear particles from printing equipment, or chemical residues from post-processing. Each type of contamination has a unique elemental fingerprint, which provides a solid scientific basis for traceability.

Process Defect Diagnosis: Linking Micro Anomalies to Macroscopic Process Parameters

SEM/EDS can directly expose issues in the 3D printing process. For example, lack-of-fusion defects appear under SEM as smooth particle boundaries and distinct gaps, while balling manifests as clusters of spherical metallic particles. Elemental segregation is revealed through backscattered electron imaging and EDS mapping. These microscopic signatures provide clear and quantitative guidance for adjusting and optimizing the process.

Typical AM Failure and Contamination Cases Analyzed by SEM/EDS

Premature Fatigue Failure of Aerospace Inconel 718 Blades

In an aerospace engine project, a batch of Inconel 718 turbine blades experienced premature fatigue failure during testing. SEM examination of the fracture origin revealed abnormal non-metallic inclusions. EDS analysis showed these inclusions to be rich in aluminum and silicon, clearly different from the base alloy composition. Further investigation traced the source to blasting media particles that were embedded during the surface treatment. During subsequent heat treatment, these hard particles acted as stress concentrators, triggering the initiation of fatigue cracks.

Internal Cracks in Medical Ti-6Al-4V Implants

In another medical device case, internal cracks were discovered in a batch of Ti-6Al-4V orthopedic implants during final inspection. SEM observations showed cracks propagating along prior β grain boundaries, indicating typical intergranular cracking. EDS detected abnormal enrichment of chlorine and potassium along the crack paths. These findings indicated that the root cause was residual chloride-containing cleaning agents, which under specific conditions induced stress corrosion cracking. Based on this, we optimized the cleaning process and eliminated the issue.

Core Value of SEM/EDS for AM Production and R&D

The value of SEM/EDS lies not only in solving existing problems, but also in preventing future ones. Through in-depth failure analysis, we transform our approach from passive "correction" to proactive "prevention." When quality fluctuations arise in production, SEM/EDS can quickly pinpoint the root cause, significantly shortening troubleshooting cycles and reducing downtime losses. More importantly, insights gained from these analyses directly support process optimization and new material development, continuously enhancing our additive manufacturing capabilities.

Collaborative Use of SEM/EDS with Other Analysis Technologies

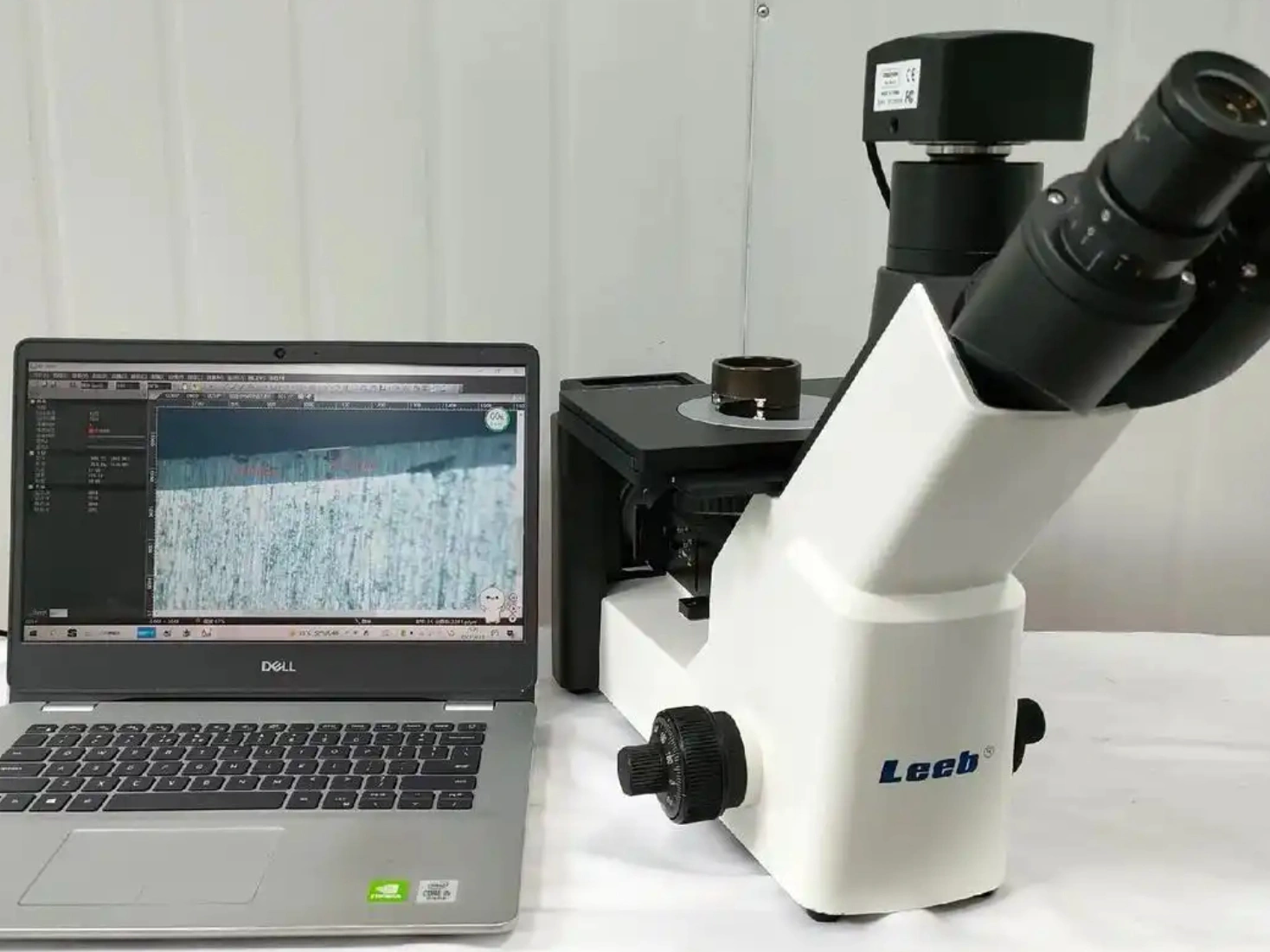

Stepwise Analysis with Stereo Microscopy

In our workflow, the stereo microscope is often used as a first-line inspection tool to quickly locate suspicious regions and assess macro-level features. SEM/EDS is then employed for high-magnification, high-resolution follow-up analysis, providing detailed morphology and compositional information. This stepwise approach from macro to micro ensures both efficiency and completeness.

Complementarity with Metallographic Analysis

Metallographic analysis reveals the distribution and morphology of defects within the bulk material through cross-sectional preparation, while SEM/EDS can then be used to perform higher-resolution imaging and local elemental analysis on specific regions of interest. Together, these techniques provide a more comprehensive picture of the microstructure and defect characteristics.

Integration with Internal Defect Inspection

When X-ray or industrial CT detects internal defects, SEM/EDS can further characterize these indications in terms of micro-morphology and chemical composition. This combination of non-destructive testing for localization and destructive analysis for characterization forms a complete analytical chain from "where is the defect" to "what is the defect".

Case Study: How SEM/EDS Resolved Batch Micro-Porosity Issues in Stainless Steel Manifolds

In an industrial project, we encountered a challenging issue: multiple batches of 316L stainless steel manifolds exhibited randomly distributed micro-pores even after hot isostatic pressing (HIP), leading to leakage during pressure testing.

We extracted samples containing these pores from failed parts and prepared them carefully for SEM observation. The micrographs revealed unusually smooth pore inner walls, distinct from typical metallurgical defects. EDS analysis detected abnormally high levels of silicon and oxygen on the pore surfaces, with ratios consistent with silicon dioxide.

Based on the spherical pore morphology and compositional data, we identified them as hollow silica microspheres. Further traceability analysis revealed that the issue originated from the powder supplier’s process, where slag-forming agents had inadvertently contaminated the material during the atomization process. We immediately switched powder batches and tightened our incoming inspection standards, thereby eliminating this long-standing quality problem.

Conclusion: Building a Quality Frontier at the Nano Scale – Turning Every Failure into a Step Forward

SEM/EDS analysis plays a crucial role in addressing the most complex and challenging quality issues in additive manufacturing. At Neway, our investment in these advanced analytical capabilities is not just about making parts; it is about delivering complete, high-level problem-solving services. Every failure case is an opportunity for us to learn and grow. Through rigorous scientific analysis, we transform failures into drivers of continuous improvement. We sincerely invite customers who are facing recurring quality issues or sudden failures to leverage our professional SEM/EDS analysis services, and together, build a robust quality defense starting from the nanoscale.

Frequently Asked Questions

What are the typical spatial resolution and minimum detectable particle size for SEM/EDS?

How should samples be prepared for SEM/EDS? Is the preparation destructive?

How long does a complete SEM/EDS-based failure analysis usually take?

Can you analyze light elements such as carbon, oxygen, and nitrogen? What is the accuracy?

Do you provide formal reports that include all raw data and expert interpretations?