Metallographic Microscopy: Microstructure & Heat-Treat Validation

Introduction: Unlocking the Secret Language of Materials – How Metallographic Microscopy Decodes the Microscopic World of 3D Printed Parts

In the field of additive manufacturing, it is often said that "microstructure determines macro performance." As a metallographic analysis engineer at Neway, my daily work involves using metallographic microscopy as a bridge to interpret the "codes" left by materials throughout the 3D printing process. The morphology of every grain and the distribution of every phase tell the story of how a part was manufactured. Especially for heat treatment process validation, metallographic analysis provides the most direct and reliable evidence, helping us ensure that every material performance verification meets design requirements.

Overview of Metallographic Microscopy Technology

Working Principle: From Sample Preparation to Microscopic Imaging

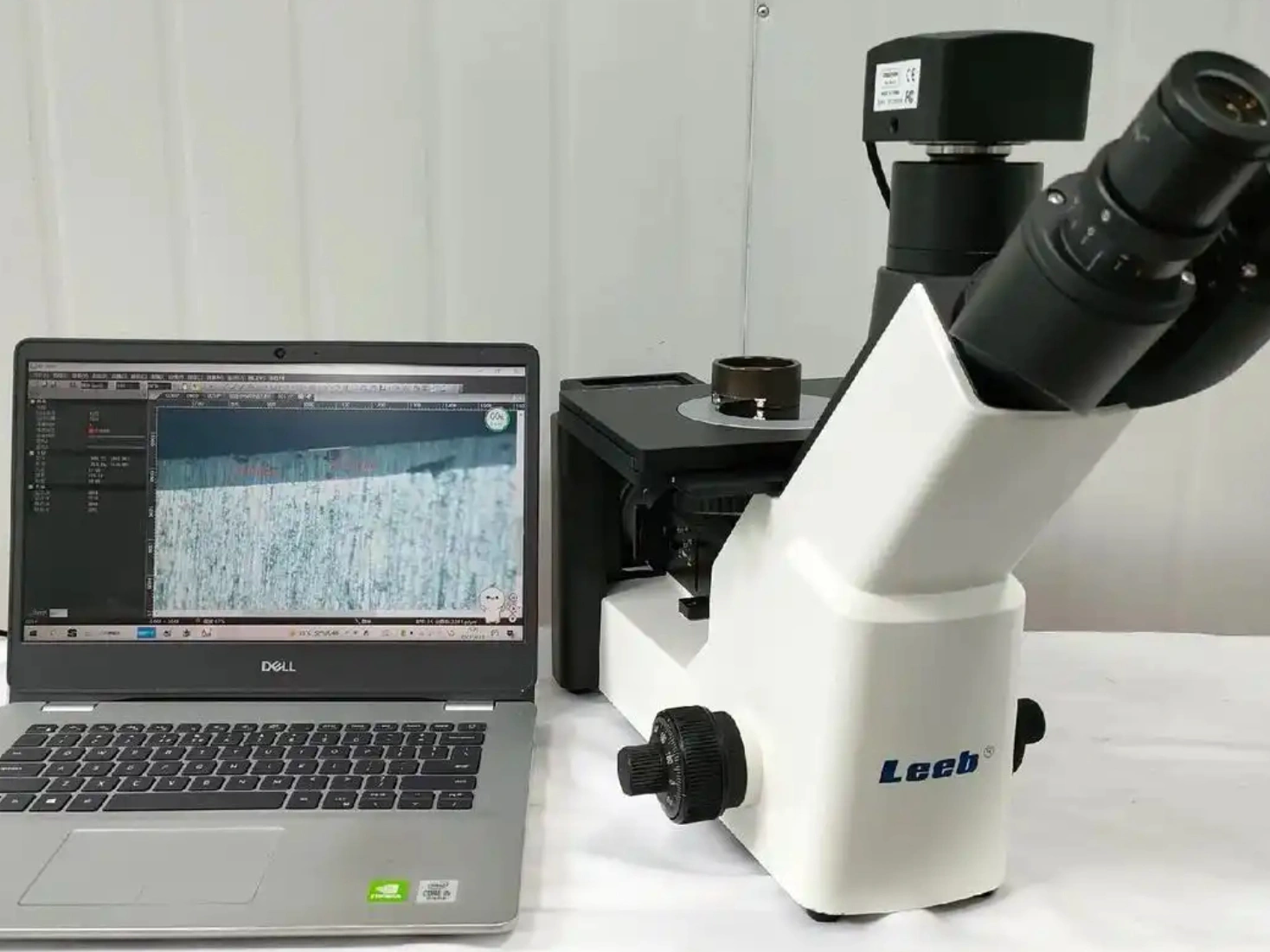

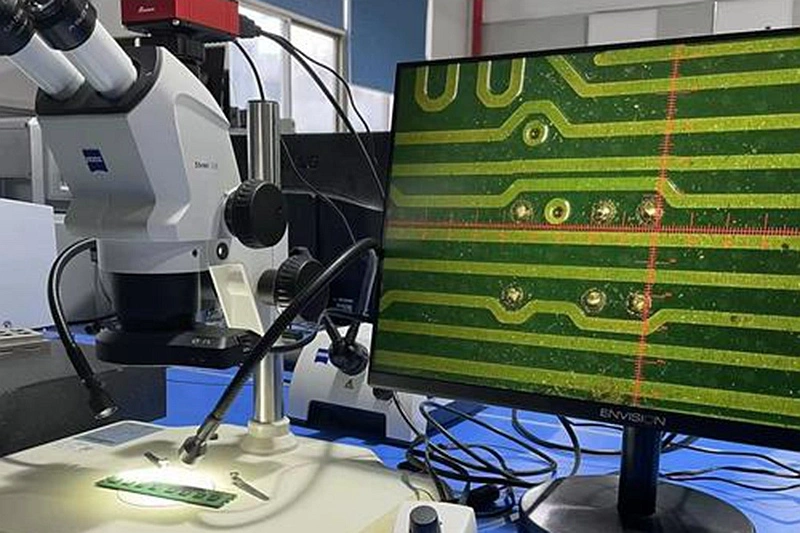

Metallographic analysis is a rigorous scientific process. First, we extract representative samples from specific locations of the part, a step that relies heavily on experience to ensure the sampling position accurately reflects the overall condition of the part. The samples are then subjected to mounting, grinding, and polishing, followed by appropriate chemical etching to reveal their microstructure. In Neway’s laboratory, we use advanced metallographic microscopes equipped with digital imaging systems, enabling us to observe micro-scale structural features and perform precise quantitative analysis.

Why Is Microstructure So Critical for 3D Printed Parts?

Microstructure is the "genetic code" of material properties. Grain size directly affects strength and toughness—according to the Hall-Petch relationship, finer grains generally result in higher strength. The composition and distribution of phases determine hardness, wear resistance, and corrosion resistance. For parts intended for high-temperature service, such as those produced via high-temperature alloy 3D printing, the stability of the microstructure is crucial to service life. Through metallographic analysis, we can predict in-service performance in advance and mitigate risks before they occur.

How Neway Integrates Metallographic Analysis into End-to-End AM Quality Control

Process Development: Establishing Microstructure–Performance Correlations

During the development of new metal materials or process parameters, we utilize systematic metallographic analysis to establish reference microstructure libraries. For example, when developing printing parameters for a new nickel-based superalloy, we study how microstructure evolves under different laser powers and scan speeds to identify a process window that produces an optimal fine dendritic structure. These foundational studies provide essential technical support for stable mass production.

Heat Treatment Validation: The Gold Standard for Evaluating Process Effectiveness

Heat treatment is a crucial step in tailoring the microstructure and performance of 3D-printed parts. We use metallographic analysis to verify whether each heat treatment batch achieves the expected outcome. For martensitic stainless steels, for instance, we confirm that they have undergone proper solution and aging treatments to obtain uniform tempered martensite. Any deviation in the process is clearly reflected in the microstructure, enabling us to promptly refine process parameters.

Batch Quality Monitoring and Root Cause Analysis of Failed Parts

In mass production, we periodically perform sampling-based metallographic inspections. When abnormalities arise, metallographic analysis becomes a critical tool for root cause investigation. By comparing the microstructures of conforming and non-conforming parts, we can determine whether issues stem from raw materials, printing parameters, or post-processing, providing clear direction for corrective actions.

Microstructure Analysis and Heat Treatment Validation for Typical 3D Printing Materials

α+β Phase Transformation in Titanium Alloys

For titanium alloy parts, metallographic analysis ensures that the microstructure matches application-specific requirements. In Ti-6Al-4V, our goal is to achieve a uniform basket-weave (Widmanstätten) microstructure through appropriate heat treatment, providing an optimal balance of strength and toughness. The presence of coarse prior β grain boundaries or continuous grain-boundary α indicates that heat treatment parameters require adjustment.

γ' Strengthening Phase in Superalloys

For nickel-based superalloys such as Inconel 718, we focus on the precipitation behavior of γ'' and γ' strengthening phases. Metallographic analysis enables us to examine the size, distribution, and volume fraction of these precipitates, thereby assessing whether aging treatments are sufficient. Ideally, fine strengthening phases should be uniformly dispersed within the γ matrix to ensure excellent high-temperature performance.

Phase Composition in Martensitic Stainless Steels

For precipitation-hardening stainless steels such as 17-4PH, metallographic analysis verifies whether heat treatment results in a uniform tempered martensitic matrix, along with copper-rich precipitates of appropriate size and distribution. These microstructural characteristics directly determine strength and corrosion resistance and are therefore key indicators in quality control.

Core Value of Metallographic Analysis for AM Production and R&D

The value of metallographic analysis lies in its ability to deliver direct visual feedback for process optimization. When microstructures observed under the microscope deviate from the ideal state, we can adjust process parameters in a targeted manner. Metallography also ensures consistency and reliability between different heat treatment batches, supporting stable product performance. More importantly, it offers clear, visual explanations for material behavior and part failures, making it an indispensable tool for solving complex technical challenges.

Synergy Between Metallographic Analysis and Other Testing Technologies

Data Correlation with Mechanical Testing

We correlate metallographic results with mechanical testing data to establish quantitative relationships between microstructure and macroscopic properties. For example, by statistically analyzing yield strength across samples with different grain sizes, we verify the applicability of the Hall-Petch relationship. This correlation greatly deepens our understanding of material behavior.

Integrated Use with SEM/EDS

When metallographic analysis reveals abnormal regions, we further employ SEM/EDS for in-depth investigation. This combined approach leverages metallography’s rapid localization and SEM/EDS’s high-resolution imaging and compositional analysis, enabling efficient and accurate characterization of defects.

Verification and Complement to Industrial CT and Other NDT Methods

When industrial CT or other non-destructive testing identifies internal anomalies, metallographic analysis provides the most direct means of confirming the nature of those indications. By examining precise cross-sections, we can determine the true morphology and type of defects, achieving perfect complementarity between non-destructive evaluation and destructive verification.

Case Study: How Metallographic Analysis Identified the Root Cause of Subpar Fatigue Performance in a Batch of Ti-6Al-4V Parts

Last year, we encountered a challenging issue: a batch of Ti-6Al-4V structural components for aerospace applications exhibited inconsistent results in high-cycle fatigue tests, with some parts falling significantly short of the design life.

We immediately launched a detailed investigation. Metallographic samples were taken from both conforming and non-conforming parts. The results showed that underperforming parts contained coarse prior β grains and large needle-like α structures, while compliant parts exhibited uniformly fine basket-weave microstructures. This clear microstructural contrast indicated excessive local heat input during printing.

Further analysis revealed that slight contamination on one of the laser optics had caused locally elevated energy density. Additionally, minor fluctuations in temperature during hot isostatic pressing (HIP) further aggravated microstructural coarsening. The combination of these factors led to degraded fatigue performance.

Based on these findings, we enhanced our equipment maintenance protocols and optimized HIP parameters. All subsequent parts passed fatigue testing. This case highlights the crucial role of metallographic analysis in resolving complex quality issues.

Conclusion: Building an Unshakable Quality Foundation at the Microscopic Scale

In the world revealed by the metallographic microscope, we see more than just microstructures—we see the solid foundation of quality assurance. At Neway, we firmly believe that a profound understanding of the microscopic world is the prerequisite for achieving exceptional macroscopic performance. Metallographic analysis, a classic discipline in materials science, has gained new vitality in the era of 3D printing and continues to provide indispensable technical support. We welcome all customers with stringent internal quality requirements to experience our science-based custom manufacturing services, and to join us in exploring the secrets of superior performance within the microscopic realm.

Frequently Asked Questions

How long does it typically take to obtain metallographic analysis results?

Can you quantitatively determine grain size or porosity levels based on metallographic analysis?

Which 3D printing materials are suitable for metallographic analysis?

Under what circumstances is metallographic analysis recommended or required?