Equipos de Ensayo Avanzados

Ensayos de Piezas Personalizadas y Aseguramiento de la Calidad

Los Ensayos de Piezas Personalizadas y el Aseguramiento de la Calidad garantizan que los componentes impresos en 3D cumplan con los más altos estándares de rendimiento, durabilidad y precisión. A través de rigurosas pruebas e inspecciones, validamos la funcionalidad, las propiedades del material y la exactitud dimensional, asegurando la fiabilidad para diversas aplicaciones.

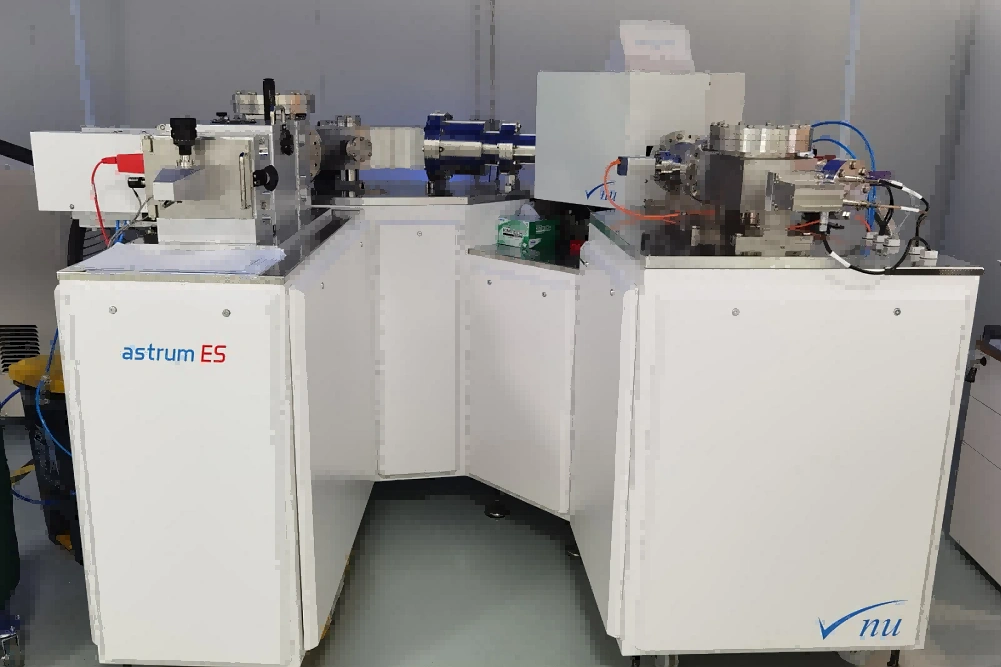

Espectrómetro de Masas por Descarga Lumínica (GDMS)

El Espectrómetro de Masas por Descarga Lumínica (GDMS) ofrece análisis elemental de ultra-traza para piezas impresas en 3D, garantizando pureza y consistencia del material. Identifica impurezas hasta niveles de ppb, crítico para aplicaciones aeroespaciales, médicas y de alto rendimiento. GDMS apoya el aseguramiento de calidad detectando contaminación de polvos, procesos de impresión y tratamientos de posprocesado.

Analizador de Carbono-Azufre

El Analizador de Carbono-Azufre es esencial para evaluar el contenido de carbono y azufre en piezas metálicas impresas en 3D, garantizando el cumplimiento de las especificaciones del material. Utiliza combustión a alta temperatura y detección infrarroja para ofrecer análisis elemental precisos. Este ensayo (no destructivo para la pieza final del cliente) verifica la consistencia química, detecta contaminación y asegura el rendimiento y la fiabilidad en aplicaciones aeroespaciales, automotrices y médicas.

Inspección por Rayos X

La Inspección por Rayos X permite evaluación no destructiva de alta resolución de estructuras internas en piezas impresas en 3D. Detecta porosidad interna, grietas, inclusiones y defectos de fusión, asegurando la integridad mecánica y el cumplimiento de estrictos estándares de calidad. El análisis por rayos X es esencial para validar componentes de seguridad en aplicaciones aeroespaciales, médicas, automotrices e industriales.

Microscopía Metalográfica

La Microscopía Metalográfica proporciona análisis de alta resolución de microestructuras en piezas impresas en 3D. Revela morfología de grano, distribución de fases, porosidad y defectos mediante secciones pulidas. Esta técnica asegura el control del proceso, verifica la eficacia del tratamiento térmico y respalda la cualificación de componentes aeroespaciales, médicos e industriales de alto rendimiento con estrictos estándares metalúrgicos.

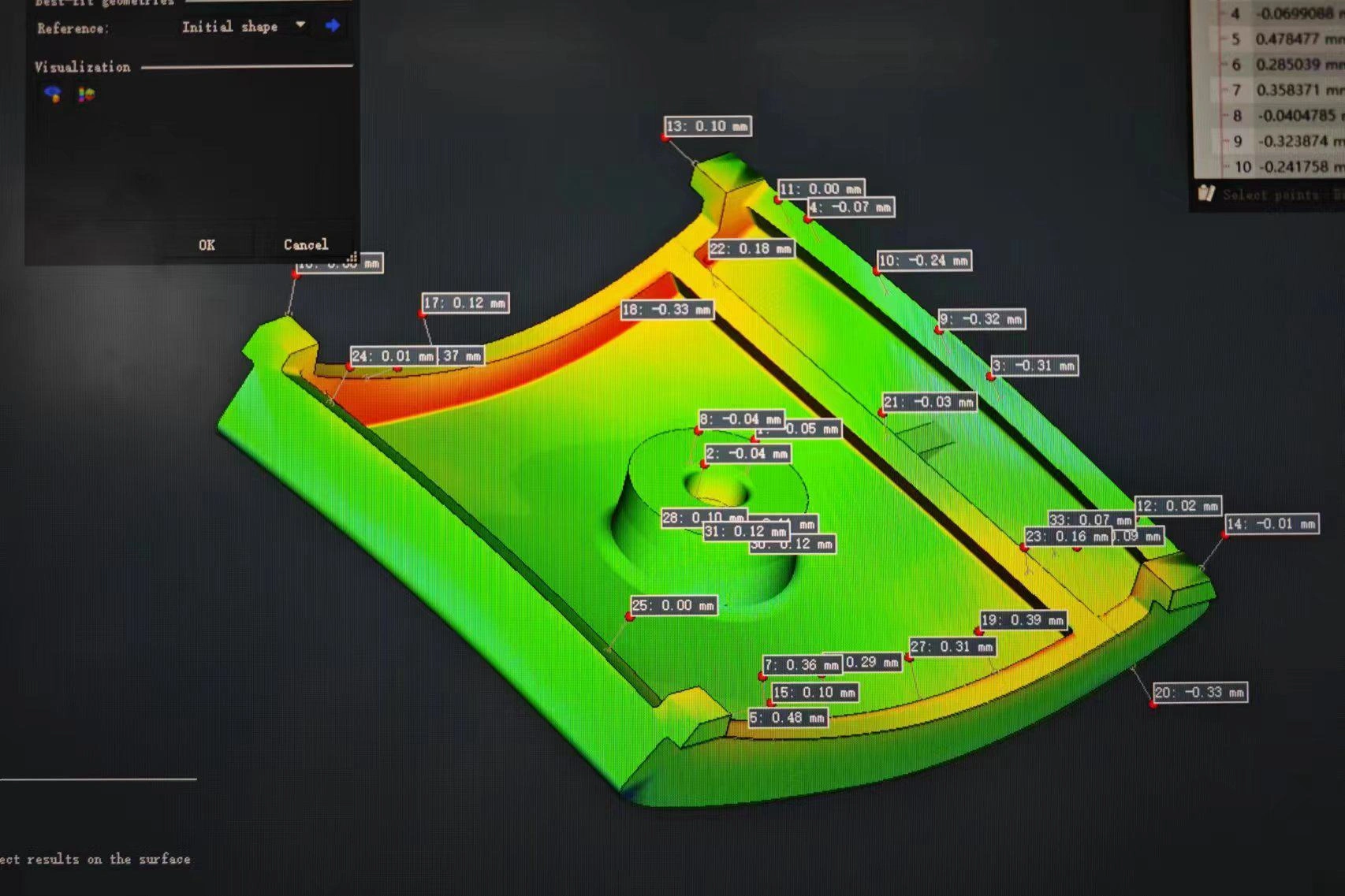

Instrumento de Medición por Escaneado 3D

El Instrumento de Medición por Escaneado 3D permite inspección dimensional de alta precisión y sin contacto de piezas impresas en 3D. Captura la geometría completa de la superficie, identificando desviaciones respecto a los modelos CAD con precisión a nivel micrón. Esta tecnología soporta la inspección de primera pieza (FAI), la ingeniería inversa y la validación de procesos en aplicaciones aeroespaciales, automotrices, médicas e industriales.

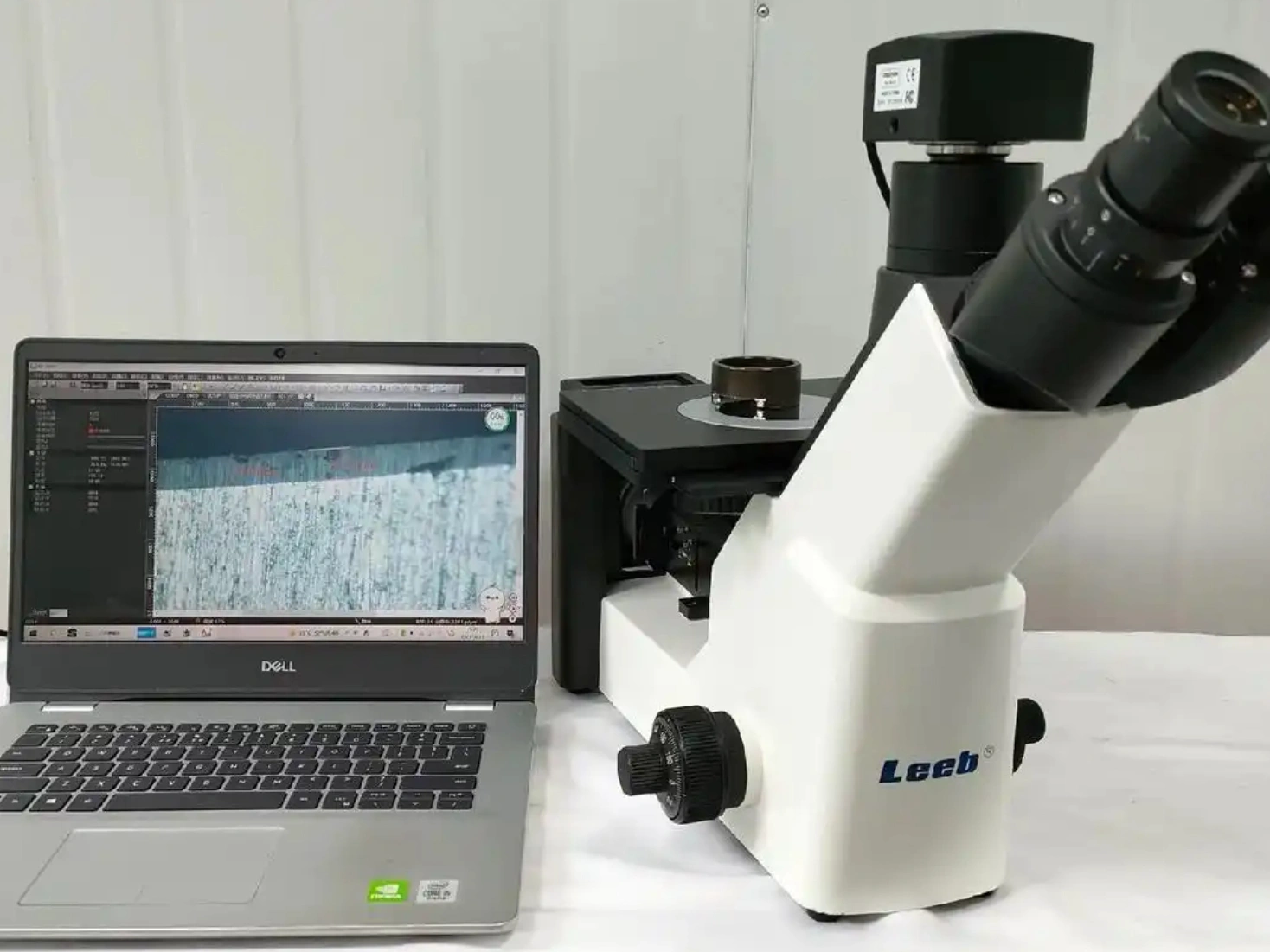

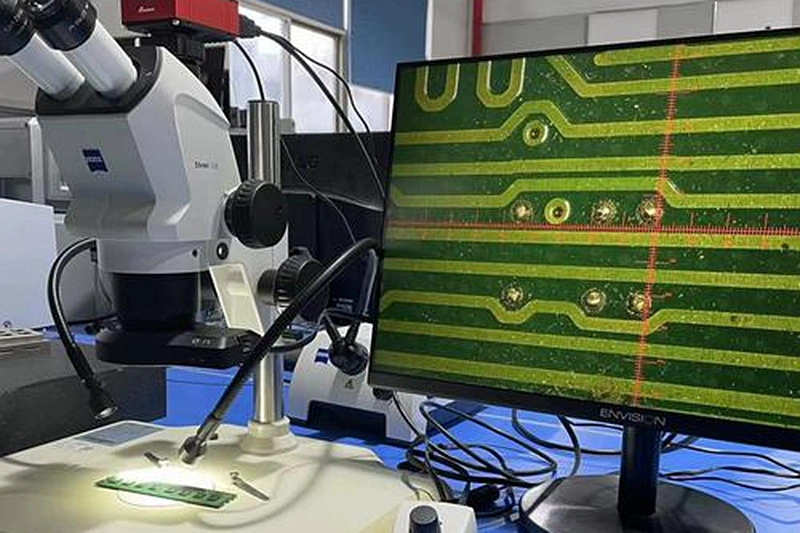

Microscopio Estereoscópico

El Microscopio Estereoscópico ofrece inspección visual tridimensional de alto aumento para piezas impresas en 3D. Permite examinar con precisión la textura superficial, la calidad de bordes y microdefectos como grietas, delaminaciones y fusión incompleta. Es esencial para la verificación de calidad superficial, inspección de ajustes y análisis de fallos en aplicaciones aeroespaciales, médicas y de fabricación de precisión.

Microscopio Electrónico de Barrido (SEM)

El Microscopio Electrónico de Barrido (SEM) ofrece imágenes de alta resolución y análisis composicional de piezas impresas en 3D. Revela características microestructurales, morfología superficial y mecanismos de defecto a escala nanométrica a micrométrica. SEM es esencial para validar la calidad del proceso, optimizar el rendimiento del material y apoyar el análisis de fallos en aplicaciones aeroespaciales, médicas e industriales avanzadas.

Máquina Electrónica Universal de Ensayo de Tracción a Temperatura Ambiente

La Máquina Electrónica Universal de Ensayo de Tracción a Temperatura Ambiente evalúa el rendimiento mecánico de materiales impresos en 3D bajo carga uniaxial. Mide con precisión resistencia a la tracción, límite elástico, elongación y módulo de elasticidad. Esta prueba valida propiedades del material, consistencia del proceso y cumplimiento de normas aeroespaciales, médicas e industriales para aplicaciones estructurales.

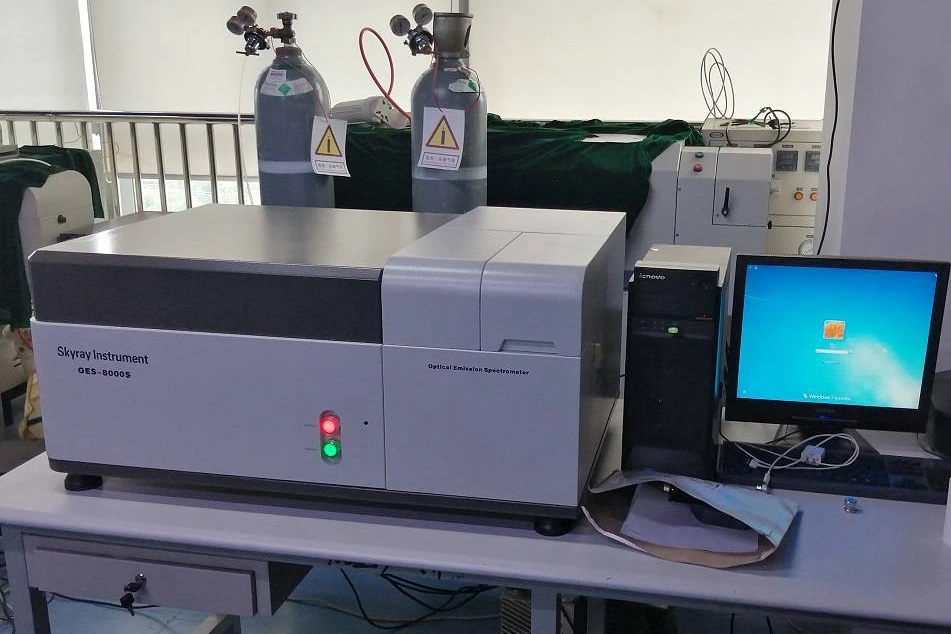

Espectrómetro de Lectura Directa

El Espectrómetro de Lectura Directa realiza análisis elemental rápido y de alta precisión de piezas metálicas impresas en 3D. Mediante espectrometría de emisión óptica (OES), cuantifica la composición de aleaciones hasta niveles de ppm. Esto asegura la consistencia del material, verifica la conformidad de la aleación y apoya el control del proceso para aplicaciones de fabricación aditiva aeroespaciales, médicas e industriales de precisión.

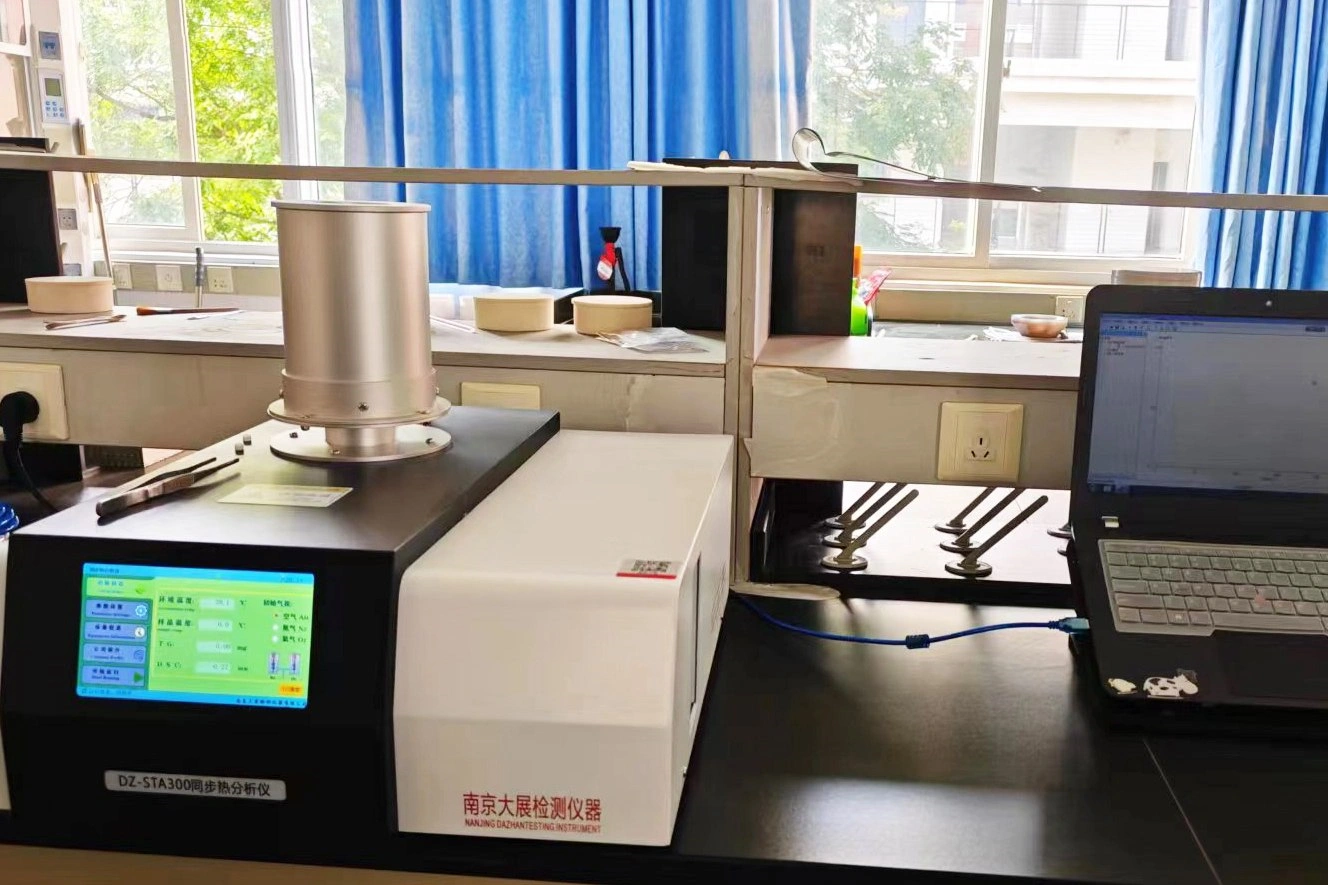

Analizador Térmico Simultáneo (STA)

El Analizador Térmico Simultáneo (STA) realiza un análisis térmico preciso de materiales impresos en 3D midiendo simultáneamente el cambio de peso (TG) y el flujo de calor (DSC). Evalúa estabilidad térmica, transiciones de fase y comportamiento de descomposición. STA apoya la cualificación de materiales, la optimización del proceso y la evaluación de fiabilidad para aplicaciones aeroespaciales, médicas e industriales de alto rendimiento.

Probador de Fatiga Dinámica y Estática

El Probador de Fatiga Dinámica y Estática evalúa el rendimiento a fatiga y la resistencia mecánica estática de componentes impresos en 3D. Simula condiciones de carga cíclica y estática para evaluar durabilidad, vida a fatiga y resistencia residual. Es esencial para aplicaciones aeroespaciales, médicas e industriales que requieren fiabilidad estructural a largo plazo validada de piezas fabricadas aditivamente.

CT Industrial de Matriz Lineal de 450KV (GE)

El CT Industrial de Matriz Lineal de 450KV (GE) proporciona imágenes 3D no destructivas de alta energía de componentes impresos en 3D. Ofrece inspección volumétrica, detección de defectos internos y metrología dimensional con precisión a nivel micrón. Es esencial para piezas aeroespaciales, médicas e industriales de precisión que requieren validación interna completa de geometrías complejas e integridad estructural.

Máquina de Medición por Coordenadas (CMM)

La Máquina de Medición por Coordenadas (CMM) proporciona inspección dimensional de alta precisión de componentes impresos en 3D. Usando palpadores táctiles u ópticos, captura geometrías complejas y verifica la conformidad con modelos CAD. La CMM es crítica para la inspección de primera pieza, validación de procesos y aseguramiento de calidad de piezas fabricadas aditivamente para los sectores aeroespacial, médico e industrial de precisión.

Comencemos un nuevo proyecto hoy