Silicon Dioxide (SiO2)

Silicon Dioxide (SiO₂), commonly known as fused silica, is a lightweight, thermally stable ceramic with excellent dielectric and thermal shock resistance. It is widely used in investment casting, microfluidic devices, and high-temperature insulation applications.

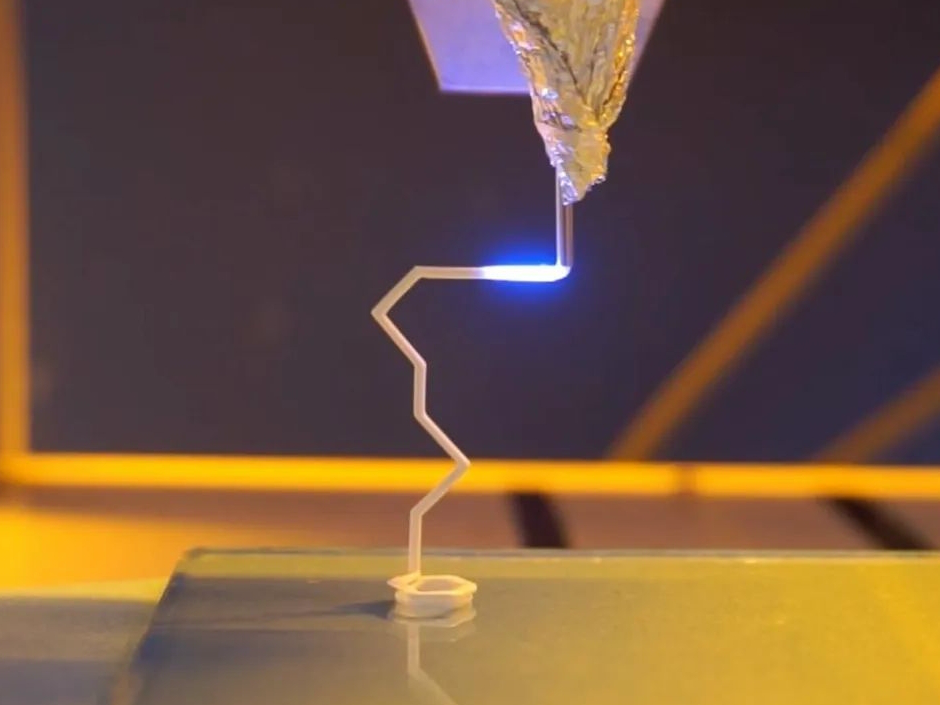

With ceramic 3D printing, complex SiO₂ parts can be fabricated with high precision and minimal post-processing. Additive manufacturing allows for internal channels, fine detail, and seamless integration of complex features into lightweight, heat-resistant structures.

Silicon Dioxide Similar Grades Table

Grade Type | Purity (%) | Typical Applications |

|---|---|---|

Fused Silica | ≥99.8 | Investment casting molds, aerospace insulation |

Quartz (Crystalline) | 99.5–99.9 | Optical components, high-frequency electronics |

Glassy SiO₂ (Amorphous) | 96–99 | Microfluidics, RF substrates, lab-on-chip devices |

Silicon Dioxide Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 2.20 g/cm³ |

Melting Point | ~1715°C | |

Thermal Conductivity (25°C) | 1.4 W/(m·K) | |

Electrical Resistivity (25°C) | >10¹⁶ Ω·cm | |

Thermal Expansion (25–1000°C) | 0.55 µm/(m·K) | |

Mechanical Properties | Hardness (Vickers) | 500–600 HV |

Flexural Strength | 60–100 MPa | |

Compressive Strength | ≥400 MPa | |

Elastic Modulus | 70 GPa | |

Fracture Toughness (K₁C) | 0.7–1.0 MPa·m½ |

3D Printing Technology of Silicon Dioxide

SiO₂ is primarily printed using Binder Jetting and Vat Photopolymerization (VPP), followed by debinding and sintering. These processes enable production of thin-walled, heat-tolerant, and highly intricate ceramic components.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

Vat Photopolymerization (VPP) | ±0.05–0.2 mm | Excellent | Good | Microfluidics, Optical Fixtures |

Binder Jetting | ±0.1–0.3 mm | Good | Moderate | Investment Casting Molds, Shells |

Silicon Dioxide 3D Printing Process Selection Principles

VPP is recommended for fine-feature applications such as microchannels and thin-walled optical or sensor components, achieving surface finishes < Ra 2 µm and high shape fidelity.

Binder Jetting is ideal for large, complex casting molds and thermal shields with moderate resolution (±0.1–0.3 mm) and excellent thermal stability after sintering.

Silicon Dioxide 3D Printing Key Challenges and Solutions

High shrinkage (~20–25%) during sintering demands accurate scaling in CAD models and the use of reliable sintering profiles. Dimensional stability is achieved by optimizing thermal gradients and support strategies.

Porosity and cracking risk are managed by controlling debinding rates and using fine powders with high packing density. Final densities of 95–98% are typical.

Low fracture toughness requires careful handling and post-processing polishing to reduce surface stress concentrators, especially for microfluidic and optical applications.

Hygroscopic behavior of silica requires storage and printing in humidity-controlled environments (RH < 40%) to prevent defect formation.

Industry Application Scenarios and Cases

Silicon dioxide 3D printing is used in:

Aerospace: Lightweight thermal insulation, RF-transparent structures, and shell cores.

Electronics: Low-loss dielectric substrates and waveguide components.

Casting: Precision investment casting molds for turbine blades and engine housings.

Medical & Lab-on-Chip: Microfluidic cartridges, sensor arrays, and inert housing components.

In a recent aerospace casting application, binder jet 3D printed fused silica molds replaced multi-part ceramic shell assemblies, reducing tooling lead time by 60% and eliminating 4 assembly steps.

FAQs

What are the advantages of 3D printing fused silica for investment casting?

How does SiO₂ compare to Alumina and Zirconia in thermal insulation?

What tolerances can be achieved in 3D printed Silicon Dioxide components?

Which industries benefit most from SiO₂ 3D printing applications?

What post-processing steps are required after sintering Silicon Dioxide parts?