What Are The 3D Printing Technologies Used for Custom Parts Additive Manufacturing?

Additive manufacturing (AM), known as 3D printing, has revolutionized custom parts production by enabling faster turnaround times, complex geometries, and cost-effective manufacturing. From rapid prototyping to end-use production, 3D printing technologies are integral to aerospace, automotive, medical, and consumer electronics industries. This blog delves into the key 3D printing technologies used for custom parts manufacturing, providing insights into each process's materials, benefits, and specific industry applications.

Additive manufacturing (AM), known as 3D printing, has revolutionized custom parts production by enabling faster turnaround times, complex geometries, and cost-effective manufacturing. From rapid prototyping to end-use production, 3D printing technologies are integral to aerospace, automotive, medical, and consumer electronics industries. This blog delves into the key 3D printing technologies used for custom parts manufacturing, providing insights into each process's materials, benefits, and specific industry applications.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies for producing plastic parts. FDM works by heating a thermoplastic filament, which is then extruded through a nozzle to form layers, one on top of the other.

Materials:

Polylactic Acid (PLA): A biodegradable thermoplastic, ideal for basic prototypes.

Acrylonitrile Butadiene Styrene (ABS): Known for its toughness and impact resistance.

Polycarbonate (PC): Offers high strength and thermal resistance.

Thermoplastic Polyurethane (TPU): Flexible and durable, used for rubber-like parts.

Applications:

Prototyping: Commonly used for prototyping in the automotive and consumer electronics industries, where design iterations and quick turnaround times are crucial.

Small-Batch Production: Ideal for low-volume custom parts production requiring moderate mechanical properties.

Functional Parts: Common for low-stress components, enclosures, and accessories.

Benefits:

Cost-Effective: Low-cost and readily available materials make FDM accessible for various industries.

Fast Production Speed: Quick setup times and reduced waste make FDM a time-efficient option for prototyping.

Material Variety: Multiple thermoplastic materials, including high-performance options like Polycarbonate (PC).

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses a powerful laser to selectively fuse powdered materials, typically nylon, into solid parts. The process builds parts layer by layer from the powder bed, offering high-strength parts without requiring support structures.

Materials:

Nylon 12: Widely used for functional prototypes and low-volume production.

Metal Powders: SLS can also be applied to metal powders such as stainless steel, aluminum, and titanium for higher-strength applications.

Glass-filled Nylon: Enhances strength and stiffness and is suitable for demanding applications.

Applications:

End-Use Parts: Ideal for parts with complex geometries, such as air ducts, internal supports, and lattice structures for aerospace and automotive industries.

Functional Prototypes: High mechanical properties make SLS suitable for testing functionality in real-world conditions.

Low-Volume Production: SLS is ideal for producing low-quantity, high-strength parts in aerospace and automotive industries where traditional manufacturing might be too costly.

Benefits:

Strength and Durability: SLS parts are tough and durable, often used in functional testing and end-use applications.

Complex Geometries: Can create highly complex shapes with internal structures that would be impossible with traditional methods.

No Support Structures: The surrounding powder acts as natural support, eliminating the need for additional support materials.

Direct Metal Laser Sintering (DMLS)

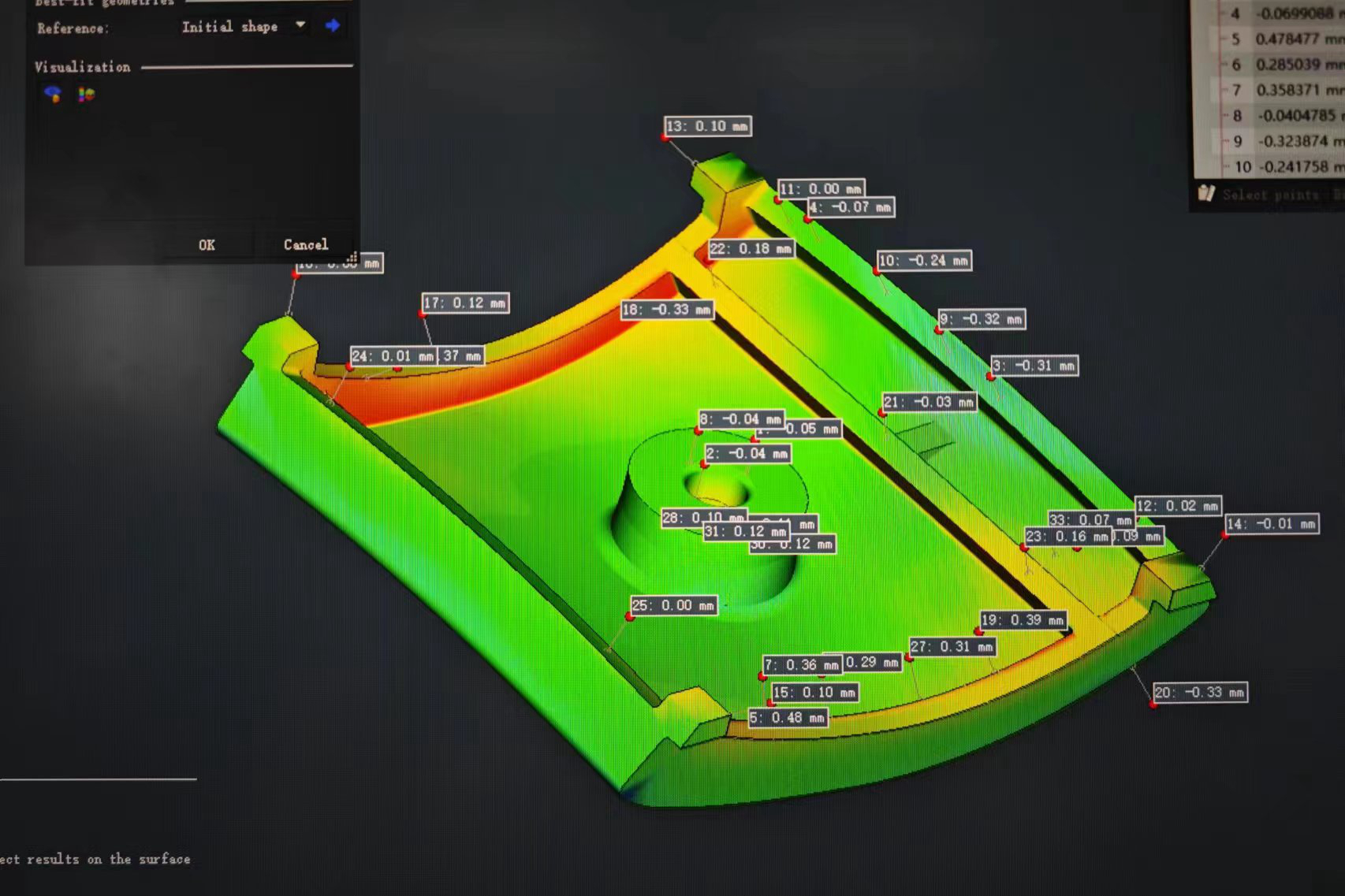

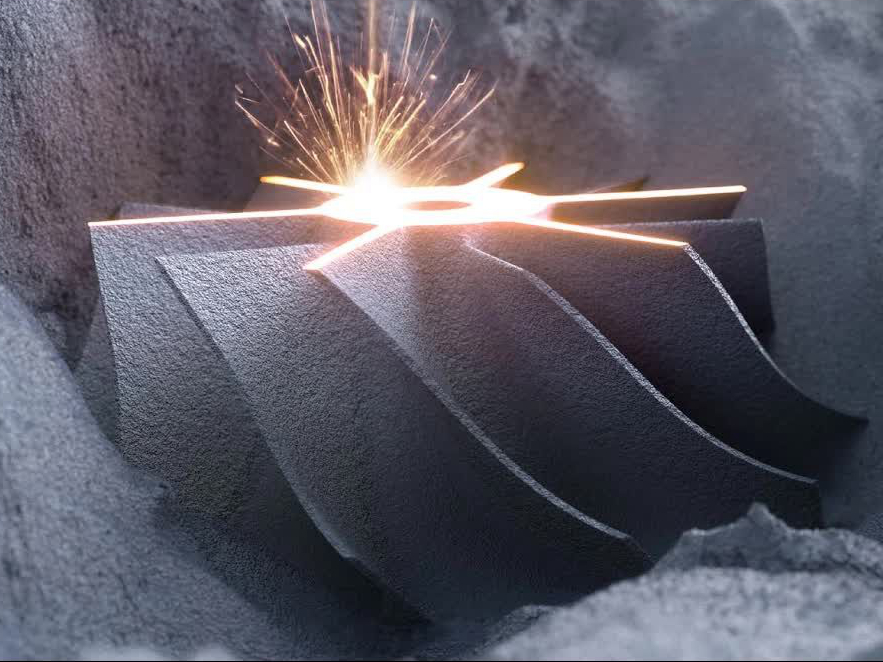

Direct Metal Laser Sintering (DMLS) is a metal 3D printing process that uses a laser to fuse metal powders into solid parts. DMLS is particularly useful for creating high-performance metal parts that require strength and thermal resistance.

Materials:

Titanium Alloys: Widely used in aerospace for their strength-to-weight ratio and resistance to high temperatures.

Stainless Steel: Common for manufacturing strong, durable parts used in the automotive and medical industries.

Inconel: Superalloys like Inconel 625 are used for parts exposed to high heat and pressure, commonly in aerospace.

Applications:

Aerospace Engine Components: Used for turbine blades, engine components, and structural elements that must withstand high temperatures and stresses.

Medical Implants: Titanium and cobalt-chrome alloys are frequently used for medical implants like joint replacements and dental parts.

Tooling: Ideal for creating highly durable tooling components such as jigs, fixtures, and dies.

Benefits:

High Strength-to-Weight Ratio: DMLS parts can be lightweight and durable, making them ideal for aerospace and automotive applications.

Material Variety: For specialized needs, a wide range of metal powders, including high-performance alloys like Inconel.

Precision: DMLS provides high-resolution parts with excellent mechanical properties.

Stereolithography (SLA)

Stereolithography (SLA) is a laser-based 3D printing technology that cures liquid resin into solid parts layer by layer. SLA is ideal for creating highly accurate and detailed parts.

Materials:

Standard Resins: Used for general prototyping.

Tough Resins: Designed to simulate the mechanical properties of ABS, ideal for functional prototypes.

Dental Resins: Biocompatible materials for dental and medical applications.

Applications:

Prototyping: Beneficial for industries requiring high detail and smooth finishes, such as the medical, dental, and jewelry sectors.

Small-Batch Production: Ideal for high-quality custom parts, such as surgical guides or dental implants.

Consumer Products: These are used to create detailed models for testing and product design in the consumer electronics industry.

Benefits:

High Precision: SLA produces parts with excellent surface finish and fine details, ideal for industries requiring high-resolution models.

Smooth Surface Finish: Minimal post-processing is required to achieve smooth surfaces.

Versatility: SLA resins can be tailored for various mechanical properties, including toughness, flexibility, and biocompatibility.

Binder Jetting

Binder Jetting uses a liquid binder to join powder materials into solid layers. Unlike other methods, this technology does not involve melting the material; instead, the binder binds the powder particles together, which are later sintered to form the final part.

Materials:

Stainless Steel: Used for creating durable metal parts, particularly for automotive and aerospace industries.

Sand and Ceramics: Used for producing casting molds and prototypes.

Applications:

Casting Patterns: Binder Jetting is widely used for creating sand or metal molds in the casting process.

Prototyping and Low-Volume Production: Ideal for producing prototypes and small batches of parts with complex geometries.

Benefits:

Cost-Effective: Suitable for low-cost production of large parts or large numbers of parts.

No Need for High Temperatures: The binder is used to bind the material rather than melting it, making it more energy-efficient.

Material Jetting

Material Jetting is a technology that deposits droplets of material onto the build platform, where each layer is cured with UV light. It allows for multi-material printing, enabling the creation of parts with varying mechanical properties in a single print.

Materials:

Flexible Resins: Used for printing parts that need to bend or stretch.

Transparent Resins: Ideal for producing clear parts, such as light housings and display components.

Applications:

Multi-Material Parts: Perfect for applications requiring different material properties in a single part.

Detailed Prototypes: Ideal for creating highly detailed prototypes for industries such as fashion, consumer electronics, and medical devices.

Benefits:

Multi-Material Printing: Ability to print multiple materials simultaneously with varying properties (e.g., soft and rigid in one part).

High Surface Quality: Produces high-quality, fine-detail parts with smooth surfaces.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is a metal 3D printing process that uses an electron beam in a vacuum to melt metal powder layer by layer, creating highly durable and dense parts.

Materials:

Titanium Alloys: Used for aerospace and medical applications.

Cobalt-Chrome: Commonly used for medical implants due to its biocompatibility and corrosion resistance.

Applications:

Medical Implants: Titanium and cobalt-chrome alloys are used to produce orthopedic and dental implants.

Aerospace Components: Ideal for parts requiring extreme strength and heat resistance.

Benefits:

Excellent Mechanical Properties: Parts made using EBM have high strength and resistance to fatigue.

Fully Dense Parts: EBM produces parts with almost no porosity, making them ideal for critical applications.

FAQs

Which 3D printing technology is best for producing high-strength metal parts?

What materials are commonly used in Stereolithography (SLA) 3D printing?

How does Direct Metal Laser Sintering (DMLS) differ from Selective Laser Sintering (SLS)?

What industries benefit most from using Electron Beam Melting (EBM) in 3D printing?

Can Continuous Liquid Interface Production (CLIP) technology be used for large-scale production?