Metal 3D Printing Services: How to Rapidly Produce Custom Metal Parts Today

Introduction

Metal 3D printing services have revolutionized the way industries produce complex, high-performance parts. Compared to traditional subtractive manufacturing, metal additive manufacturing reduces lead times by up to 70% and minimizes material waste by 50% to 80%. Advanced technologies like Powder Bed Fusion and Directed Energy Deposition enable the fabrication of intricate geometries that were previously impossible to machine. These capabilities make metal 3D printing indispensable for sectors requiring fast, custom solutions, from aerospace to medical implants.

Manufacturers can now leverage a broad spectrum of 3D printing materials—including superalloys, titanium, stainless steel, carbon steel, and copper—to achieve application-specific performance. Coupled with advanced post-processing options, metal 3D printed components today meet or exceed the mechanical properties and surface quality standards of traditionally machined parts.

The Advantages of Metal 3D Printing for Custom Parts

Faster Prototyping and Production

Metal 3D printing significantly accelerates product development cycles. Traditional CNC machining or casting typically requires weeks for tooling and setup, whereas metal additive manufacturing delivers functional prototypes or end-use parts in as little as 3–7 days. This is especially advantageous for rapid prototyping in industries such as aerospace, automotive, and consumer electronics, where iterative design validation is critical.

For example, aerospace manufacturers use metal 3D printing to reduce the time required to produce jet engine components by up to 60%, while enabling faster design changes without tooling delays.

Design Freedom and Complex Geometries

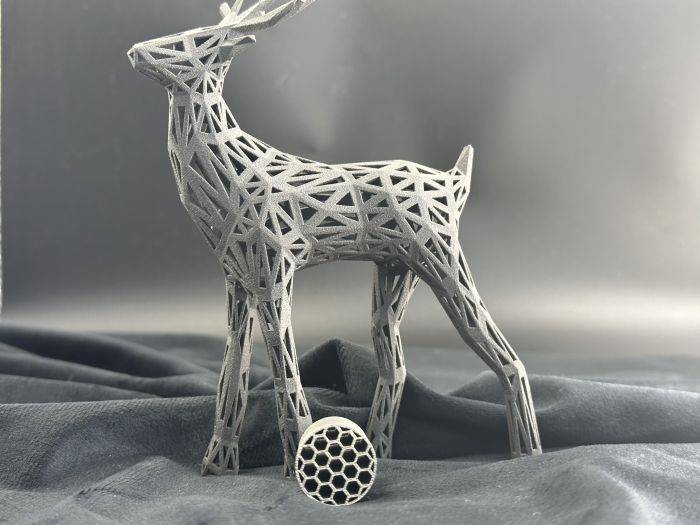

Metal 3D printing excels in producing complex structures, such as lattice designs, conformal cooling channels, and topology-optimized parts. These geometries, often unachievable with conventional methods, enhance part functionality and reduce weight. Technologies such as Powder Bed Fusion and Binder Jetting support the fabrication of highly detailed components with feature sizes down to 0.1 mm and wall thicknesses as thin as 0.3 mm.

These capabilities are ideal for industries requiring innovative designs, such as medical and healthcare for patient-specific implants and aerospace for lightweight structural components.

Cost Efficiency for Low to Medium Volumes

Metal 3D printing eliminates the need for expensive tooling, making it cost-effective for low to medium volume production. In production runs of 50–500 units, additive manufacturing can lower unit costs by 30% to 50% compared to traditional CNC or investment casting. This is particularly valuable for manufacturing and tooling applications where flexibility and customization are essential.

Additionally, material utilization is optimized, with minimal waste, resulting in more sustainable production practices and lower overall material costs.

Common Metal Materials Used in 3D Printing

Superalloys

Superalloys are engineered for extreme environments, offering exceptional strength, corrosion resistance, and thermal stability. Alloys like Inconel 625, Inconel 718, Hastelloy C-276, and Haynes 230 are commonly used in superalloy 3D printing to manufacture gas turbine blades, aerospace components, and high-temperature tooling. Components printed in Inconel 718 can maintain mechanical properties at temperatures exceeding 700 °C, with tensile strengths above 1,200 MPa.

Titanium Alloys

Titanium 3D printing delivers lightweight, high-strength parts with excellent biocompatibility and corrosion resistance. Alloys like Ti-6Al-4V (Grade 5) are widely adopted in aerospace for structural brackets and in medical implants for orthopedic and dental applications. Titanium’s strength-to-weight ratio of approximately 160 kN·m/kg makes it ideal for weight-critical components.

Stainless Steels

Stainless steel 3D printing is well-suited for functional prototypes and production parts that require durability and corrosion resistance. Grades such as SUS316L and 17-4 PH (SUS630) achieve tensile strengths exceeding 900 MPa, making them ideal for tooling inserts, chemical processing equipment, and marine components.

Carbon Steels

Carbon steel 3D printing enables the production of robust structural components and wear-resistant tooling. Tool steels such as D2 and H13 are frequently printed to create dies, cutting tools, and molds with excellent hardness and wear resistance after post-processing. Carbon steels offer yield strengths up to 1,100 MPa, providing reliable performance in demanding applications.

Copper Alloys

Copper alloy 3D printing supports the fabrication of components requiring high thermal and electrical conductivity. Alloys like C101 and CuCr1Zr are used for heat exchangers, cooling systems, and electrical contacts. Copper 3D printing enables fine-feature cooling channels with wall thicknesses under 0.5 mm, optimizing heat transfer efficiency in high-performance systems.

Leading Metal 3D Printing Technologies

Powder Bed Fusion (PBF)

Powder Bed Fusion is the most established technology for metal additive manufacturing. It uses a laser or electron beam to selectively melt fine layers of metal powder. Techniques such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM) allow for precise control over microstructure and porosity, producing parts with near-wrought mechanical properties.

PBF is capable of achieving layer thicknesses between 20–60 microns and dimensional tolerances of ±0.1 mm. It is ideal for complex, high-value components used in aerospace and aviation, medical implants, and tooling.

Directed Energy Deposition (DED)

Directed Energy Deposition builds parts by depositing metal powder or wire into a melt pool created by a focused energy source. DED supports multi-material builds and can repair or add features to existing components. With deposition rates of 50–150 cm³/hour, DED is particularly advantageous for large-scale parts and industrial tooling.

DED is commonly used in industries such as energy and power for producing or refurbishing large turbine components.

Binder Jetting

Binder Jetting is a high-speed metal printing technology that uses a liquid binder to selectively join metal powder layers. After printing, parts undergo sintering to achieve final density and mechanical properties. Binder Jetting 3D printing enables cost-effective production of large batches of complex metal parts without the need for support structures.

Binder Jetting is increasingly adopted in automotive manufacturing, where cost, scalability, and throughput are critical for functional components and series production.

Key Post-Processing for Metal 3D Printed Parts

CNC Machining for Precision Finishing

Many metal 3D printed components require post-machining to achieve final dimensional tolerances and surface finishes. CNC machining is employed to refine critical surfaces, tight tolerances (±0.01 mm), and mating features. Complex parts such as aerospace brackets and medical implants are often hybrid manufactured — combining additive with subtractive machining — to optimize both geometry and performance.

Heat Treatment for Enhanced Properties

Heat treatment plays a critical role in relieving residual stresses and enhancing mechanical properties. Depending on the material, treatments such as annealing, aging, and solution heat treatment can improve ductility, hardness, and fatigue life. For example, post-process heat treatment of titanium parts can achieve tensile strengths exceeding 1,000 MPa. In high-performance applications, processes like heat treatment post-process significantly improve resistance to wear and fatigue.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is used to eliminate internal porosity and achieve near-full density in metal printed parts. By applying high pressure (up to 200 MPa) and elevated temperatures (up to 1,250 °C), HIP enhances fatigue strength, toughness, and reliability. This is especially valuable for enhanced mechanical properties required in aerospace and energy-critical components.

Surface Treatments

Final surface treatments are applied to improve corrosion resistance, wear resistance, and cosmetic appearance. Common techniques include anodizing, passivation, electropolishing, and PVD coatings. Surface treatment ensures that metal 3D printed parts meet the required performance standards in their operational environments. For example, typical surface treatments for 3D-printed parts can achieve surface roughness (Ra) below 0.8 µm, extending component service life in harsh environments.

Industries Benefiting from Metal 3D Printing

Aerospace and Aviation

Aerospace and aviation are among the most advanced sectors in adopting metal 3D printing. The technology enables the production of lightweight, topology-optimized parts that reduce aircraft weight and improve fuel efficiency. Components such as turbine blades, heat exchangers, and structural brackets benefit from the design freedom and material performance of metal additive manufacturing. In aerospace applications, parts produced through Powder Bed Fusion exhibit high fatigue strength and temperature resistance, meeting stringent FAA and EASA certification requirements.

Automotive

The automotive industry leverages metal 3D printing for rapid prototyping, tooling inserts, and low-volume production of performance components. Metal printed parts are used in motorsport, electric vehicles, and luxury car segments to deliver optimized thermal management, weight reduction, and enhanced part integration. Binder Jetting is increasingly used to manufacture cost-effective metal components at production volumes in the thousands.

Medical and Healthcare

Medical and healthcare rely on metal 3D printing for custom implants, surgical instruments, and dental restorations. Patient-specific implants made from titanium alloys are designed from CT/MRI data, achieving a perfect anatomical fit and rapid surgical turnaround. Metal 3D printing also enables porous surface structures that promote osseointegration, improving long-term implant performance.

Energy and Power

In the energy and power sector, metal 3D printing supports the production of critical components for gas turbines, nuclear reactors, and oil and gas equipment. Superalloy parts with optimized cooling channels and internal geometries enhance thermal efficiency and extend component life in high-temperature environments. Directed Energy Deposition is widely used for repair and refurbishment of large, high-value energy components.

Consumer Electronics

Consumer electronics manufacturers use metal 3D printing to create lightweight, high-performance enclosures, connectors, and heat sinks. Copper and aluminum alloys are printed to produce advanced thermal management solutions for compact electronic devices. The ability to fabricate fine-feature components with excellent surface finishes supports the aesthetic and functional requirements of modern consumer products.

Conclusion: Why Choose Professional Metal 3D Printing Services?

Metal 3D printing offers unmatched flexibility, speed, and material performance for modern manufacturing needs. By leveraging advanced superalloy parts and stainless steel 3D printing solutions, manufacturers can rapidly produce complex custom components with superior mechanical properties and surface quality.

When combined with precision post-processing and robust material options, professional metal 3D printing services provide end-to-end solutions that meet the most demanding industry standards. From aerospace to medical to automotive sectors, businesses can now achieve faster time-to-market, greater design innovation, and improved product performance through metal additive manufacturing.