Stereolithography (SLA): An Overview of This 3D Printing Technology

Stereolithography (SLA) is one of the most precise and widely used 3D printing technologies, known for producing high-resolution models with intricate details. SLA utilizes a laser to cure liquid resin into solid layers, creating parts with accuracy that surpasses many other 3D printing methods. This process is highly favored for applications requiring fine features and smooth surfaces, making it ideal for aerospace, medical, and consumer electronics industries.

In this guide, we will explore SLA technology, how it works, its advantages, the materials it uses, and its typical applications in various industries. Whether designing prototypes or looking for high-precision end-use parts, SLA offers a reliable and efficient solution for creating complex geometries and detailed models.

How Stereolithography (SLA) 3D Printing Works

Stereolithography is an additive manufacturing process that uses a laser to cure photosensitive resin, solidifying it layer by layer. The process starts with a digital design file, usually a CAD model, which is then sliced into thin layers. A laser beam is directed onto the resin surface, which hardens in the areas where the laser is directed. This curing process continues until the part is fully formed.

Unlike other 3D printing methods, such as Fused Deposition Modeling (FDM), which extrudes filament, SLA works with liquid resin, allowing for much finer details and smoother finishes. The SLA printer typically uses a build platform submerged in the resin tank, where the laser scans each layer to harden the material selectively.

Key Features of SLA Technology

High Precision and Resolution: SLA technology is known for its superior resolution, offering layer thicknesses as small as 25 microns. This makes it ideal for creating parts with intricate geometries and smooth surfaces.

Versatile Material Options: SLA supports various photopolymer resins, each with unique mechanical properties such as rigidity, flexibility, or heat resistance. These materials make SLA suitable for various applications, including detailed prototypes, functional parts, and dental applications.

Smooth Surface Finish: SLA parts typically exhibit smoother surface finishes than other 3D printing technologies like FDM. This is particularly beneficial for parts that require post-processing or parts that will be used for molding.

The SLA 3D Printing Process

1. Material Preparation

The SLA process begins with a photosensitive resin that is available in various formulations. Some resins are clear, while others are opaque, offering a range of properties such as flexibility, toughness, or temperature resistance. SLA printers typically use a resin tank, and the material is dispensed into this tank at the start of the printing process.

2. Layer-by-Layer Curing

Once the material is prepared, the SLA printer lowers the build platform into the resin tank. A laser is then directed across the surface of the resin, curing it layer by layer according to the digital model. Each layer is hardened before the platform is lowered, and the process repeats until the part is entirely constructed.

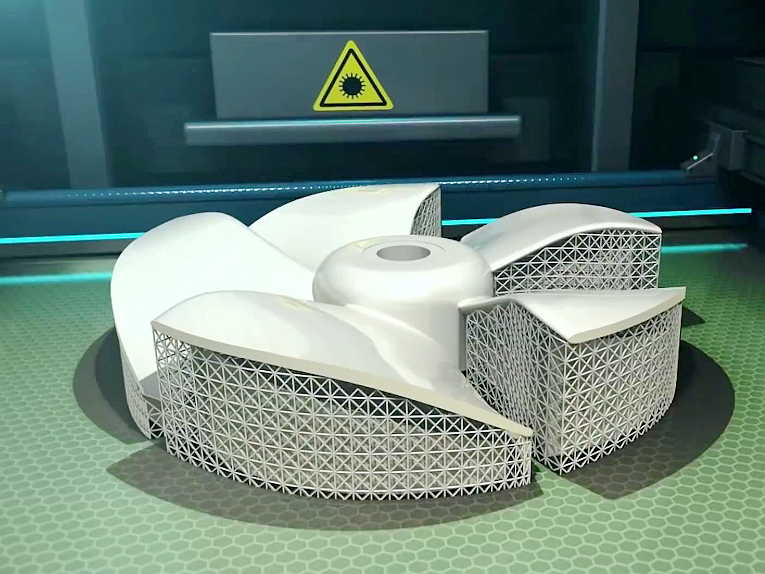

3. Support Structures

Support structures are needed for parts with overhangs or complex features to prevent distortion during the curing process. These supports are typically made from a different resin or a soluble material, which can be easily removed after the print is complete. SLA printers are equipped with support generation tools that automatically create the necessary supports for the model.

4. Post-Processing

After printing, SLA parts undergo post-processing, typically washing the part in isopropyl alcohol to remove any uncured resin. Once cleaned, the parts are subjected to post-curing, often using ultraviolet (UV) light or heat, to harden the material further and enhance its mechanical properties.

Materials Used in SLA 3D Printing

SLA 3D printing supports various resin materials, each designed for different applications. Below is a comparison table highlighting some of the most commonly used SLA resins and their properties:

Material | Properties | Applications |

|---|---|---|

Smooth finish, excellent resolution, rigid | Prototypes, models, architectural models | |

Impact-resistant, similar to ABS, high durability | Functional prototypes, mechanical parts, tooling | |

Biocompatible, ideal for dental applications | Dental models, crowns, bridges, orthodontic devices | |

Transparent finish, can be polished for clarity | Medical applications, lenses, prototypes requiring clarity |

Advantages of SLA 3D Printing

High Accuracy: SLA produces parts with wonderful details, making it ideal for precision applications, such as jewelry, dental models, and small intricate components.

Smooth Surface Quality: Unlike FDM and other 3D printing methods, SLA parts generally require little post-processing to achieve a smooth surface finish, reducing the time spent on sanding or polishing.

Wide Material Range: SLA supports a variety of materials with specific properties, such as high-temperature resistance, flexibility, or biocompatibility, making it versatile for many industries.

Speed and Efficiency: While SLA printing can be slower than FDM, it is often faster than traditional manufacturing methods when producing small or intricate parts.

Common Applications of SLA 3D Printing

SLA is highly versatile and is used in a variety of industries for applications requiring precision and fine detail:

Prototyping: SLA is widely used for rapid prototyping, especially in consumer electronics and automotive industries. Its ability to quickly produce highly detailed parts makes it an invaluable tool in product development.

Medical and Dental: SLA technology is commonly used in the medical industry for custom implants, surgical guides, and anatomical models. The accuracy of SLA makes it ideal for creating highly detailed medical devices and dental molds.

Jewelry and Fashion: SLA is also popular in the jewelry industry for creating highly detailed wax patterns for casting. The fine details and smooth surface finish allow jewelers to develop complex designs easily.

Aerospace: SLA is used to manufacture high-precision parts and prototypes in aerospace. Its ability to handle complex geometries and achieve tight tolerances is crucial for flight testing and production parts.

Why Choose SLA 3D Printing?

SLA 3D printing is an excellent choice for applications that require high precision and intricate details. Producing smooth, high-resolution parts quickly and efficiently makes it a valuable technology for rapid prototyping and small production runs. Whether you're in medical, aerospace, or consumer goods, SLA provides a reliable solution for creating functional, high-quality components.

To learn more about SLA 3D printing and other 3D printing technologies, visit our website.

FAQs:

What is the difference between SLA and FDM 3D printing technologies?

How can SLA be used in the medical field?

What materials are best suited for SLA 3D printing?

How does SLA provide better surface finish compared to other 3D printing methods?

What industries benefit most from SLA 3D printing?