Metal 3D Printing vs CNC Machining: Which is More Cost-Effective for Custom Parts?

Introduction

In today’s advanced manufacturing landscape, both metal 3D printing and CNC machining are essential technologies for producing high-performance custom parts. Designers and procurement teams increasingly evaluate cost-effectiveness as a key factor when selecting the optimal process for a project.

Metal additive manufacturing offers unparalleled design freedom and material efficiency, while CNC machining delivers superior precision and surface finish for established geometries. Depending on production volume, complexity, and material requirements, each technology presents distinct cost advantages.

This blog provides a detailed comparison of metal 3D printing and CNC machining, analyzing their respective cost drivers across various manufacturing scenarios. With insights into process capabilities, material utilization, and post-processing requirements, this guide will help engineers and buyers make informed decisions when sourcing custom metal parts.

Core Differences Between Metal 3D Printing and CNC Machining

Core Differences Between Metal 3D Printing and CNC Machining

Process Overview

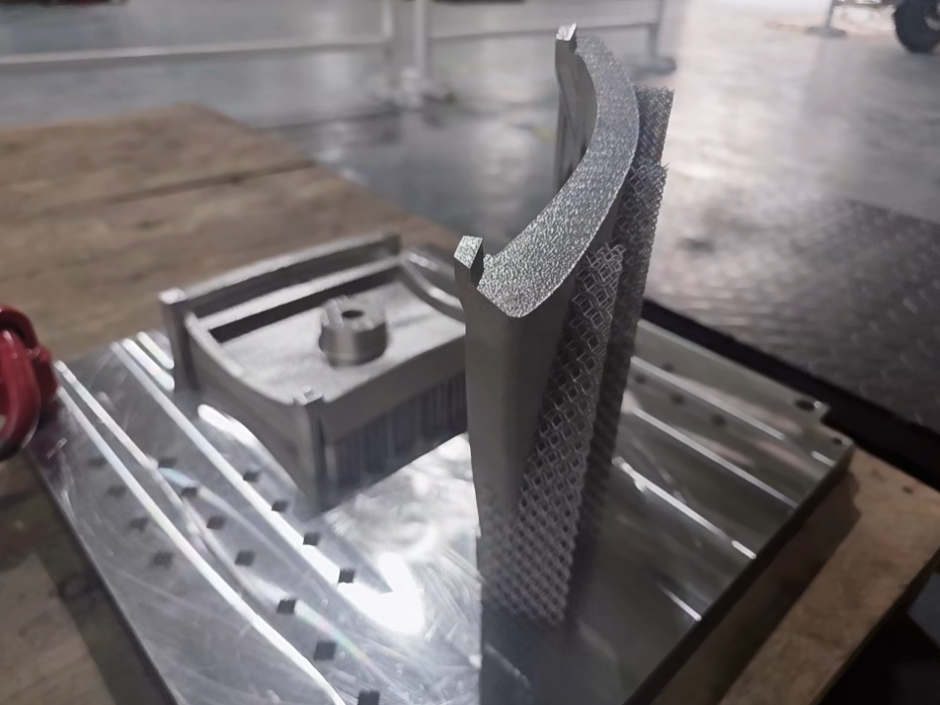

Metal 3D printing is an additive process where parts are built layer by layer from digital designs, enabling highly complex geometries without the need for tooling. Common technologies include Powder Bed Fusion and Directed Energy Deposition. In contrast, CNC machining is a subtractive process that removes material from a solid block (billet) using computer-controlled cutting tools.

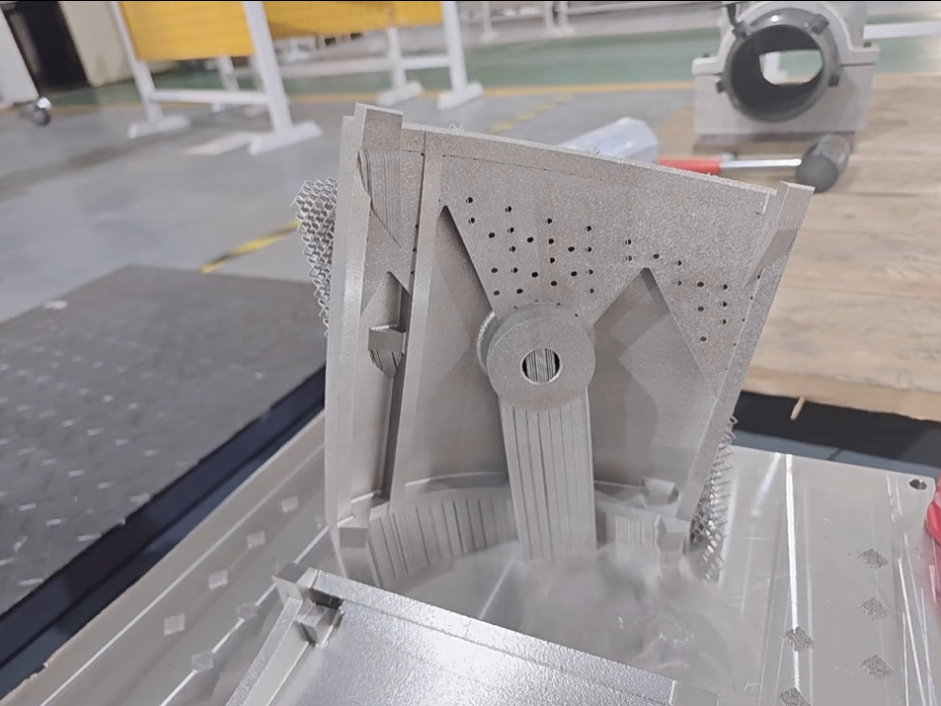

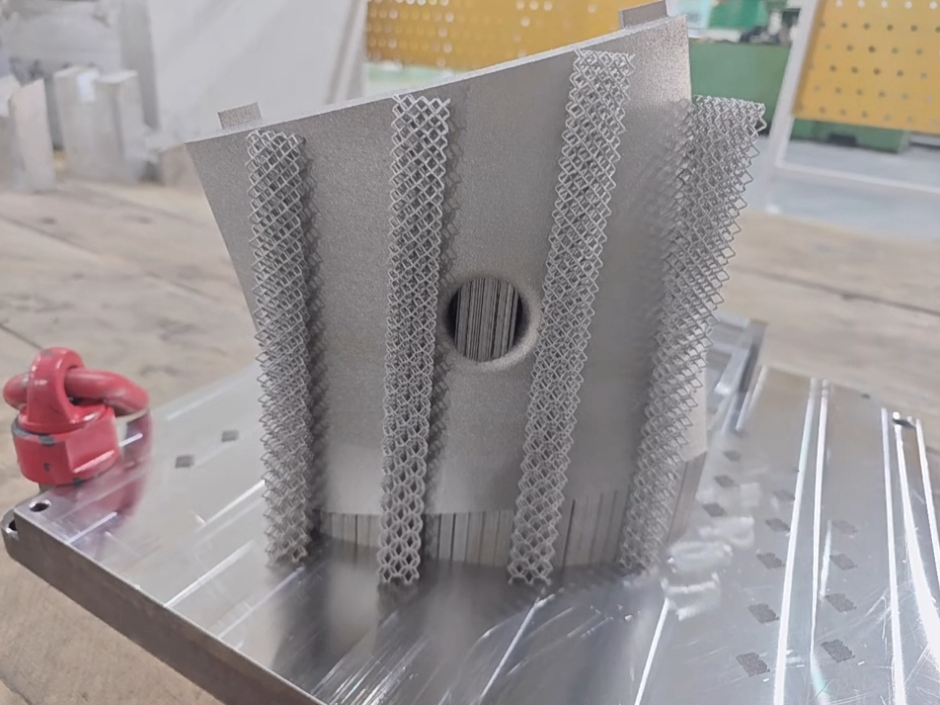

Both processes are digitally driven but fundamentally different in material flow and geometric possibilities. For components with internal channels or lattice structures, metal additive manufacturing offers unmatched design flexibility. CNC machining excels in precision parts with well-defined surfaces and tight tolerances.

Design Freedom

Metal 3D printing allows for freeform geometries such as integrated cooling channels, lattice structures, and topologically optimized parts—designs that are impossible or highly inefficient to produce through traditional methods. Engineers using 3D printing technologies for custom parts manufacturing can consolidate multiple components into a single printed part, reducing assembly complexity.

Conversely, CNC machining provides superior control for external surfaces and sharp edges, making it ideal for mating components and assemblies requiring ±0.01 mm tolerances. It is also highly effective for producing parts with large planar surfaces and simple prismatic geometries.

Material Compatibility

Both technologies support a broad range of metals, though with different limitations. Metal 3D printing efficiently processes high-value materials like titanium, superalloys, and stainless steel. For example, carbon steel 3D printing is frequently used for structural components where the strength-to-weight ratio is critical.

CNC machining offers even wider material flexibility, including hardened steels, exotic alloys, and non-metallics such as composites. Machinability, material hardness, and tool wear must be factored into cost calculations when comparing to 3D printing.

Summary

When comparing core differences, metal 3D printing dominates in geometrical complexity and material efficiency, whereas CNC machining offers superior precision and scalability for well-established part designs. The choice between these technologies often depends on specific project requirements, which will be further explored in the next sections.

Cost Factors for Metal 3D Printing

Setup and Tooling Costs

One of the primary advantages of metal 3D printing is the minimal upfront investment. Unlike CNC machining or casting, no custom tooling, molds, or fixtures are required. This is particularly valuable for short production runs or prototype development. With superalloy 3D printing, complex aerospace or energy components can move from digital model to physical part with significantly reduced lead time and startup costs.

This flexibility also enables engineers to iterate designs rapidly without incurring additional tooling expenses—a key factor in industries where agility is critical.

Material Utilization and Waste

Metal additive manufacturing is highly efficient in material usage. Powder Bed Fusion processes typically achieve 95%–98 % material utilization, as unused powder is reclaimed and recycled for future builds. In contrast, CNC machining removes large volumes of material from solid stock, often resulting in 50%–70% material waste, especially for complex geometries.

This material efficiency is particularly impactful when working with expensive alloys such as titanium or Inconel, where raw material costs dominate the total part cost.

Lead Time and Production Speed

Metal 3D printing offers exceptionally fast turnaround for low to medium volume production. Parts can often be printed and delivered within 3–7 days, bypassing long lead times associated with traditional manufacturing. This is why rapid prototyping for critical industries like aerospace and medical has embraced metal AM.

For custom parts in quantities of 1–100, the per-unit cost of metal 3D printing is typically lower than CNC machining, especially when considering reduced design-to-production cycle times.

Post-Processing Requirements

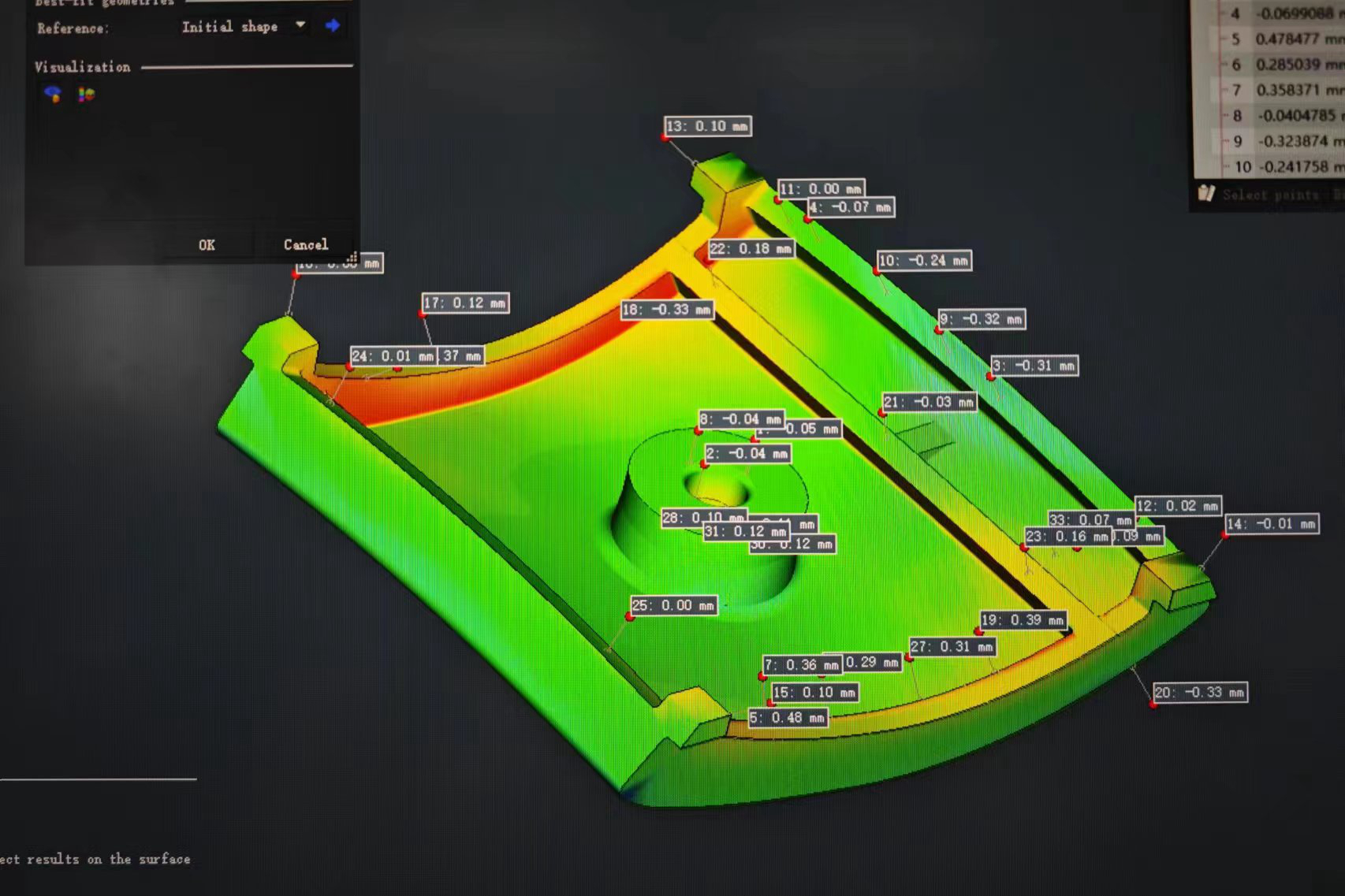

Post-processing is an important cost factor in metal 3D printing. Depending on the application, parts may require heat treatment, HIP, and machining to achieve the required mechanical properties and surface finishes. Standard heat treatment is used to optimize material performance, while hot isostatic pressing (HIP) improves density and fatigue life.

While these steps add to the total cost, they are comparable to secondary processes used in CNC machining (grinding, polishing), and for many applications, the overall part cost remains competitive when considering the advantages in lead time and design freedom.

Cost Factors for CNC Machining

Setup and Programming Costs

CNC machining requires upfront investment in both programming and fixture setup. For each new part, CAM (Computer-Aided Manufacturing) programming is required to generate tool paths, which can be time-consuming for complex geometries. Additionally, custom jigs or fixtures are often needed to securely hold parts during machining, especially for multi-axis operations.

While these setup costs are amortized over large production volumes, they can make CNC machining less cost-effective for prototypes or short runs compared to metal 3D printing.

Machining Time and Tool Wear

Material hardness and geometry complexity directly impact CNC machining costs. For example, machining Inconel 718, a superalloy commonly used in aerospace, requires specialized tooling and reduced feed rates due to its work-hardening behavior. This increases machining time and accelerates tool wear, leading to higher operational costs.

Additionally, intricate internal geometries or undercuts often require complex setups or cannot be machined at all, further driving up costs when compared to additive manufacturing.

Material Waste and Efficiency

CNC machining is inherently wasteful, particularly when starting with billet material for complex parts. Material removal rates can result in 50%–70% of the raw material being converted to chips, especially when machining parts with hollow features or organic geometries.

By contrast, stainless steel 3D printing processes produce near-net-shape parts with minimal waste, making AM more efficient for high-value materials.

Surface Finish and Tolerances

CNC machining excels at achieving tight tolerances and superior surface finishes. Standard CNC operations can deliver dimensional accuracy of ±0.01 mm or better and surface finishes down to Ra 0.4–0.8 µm, which is critical for mating parts and functional surfaces.

For components requiring mirror-like finishes or ultra-precise features, EDM is often used. Techniques such as EDM machining for mirror surfaces further enhance finish quality, though they add processing time and cost.

When is Metal 3D Printing More Cost-Effective?

Low to Medium Volume Production

Metal 3D printing is particularly cost-effective for low to medium volume production, typically in the range of 1 to 500 parts. Because there is no need for tooling or fixtures, additive manufacturing eliminates the high setup costs associated with CNC machining. This enables cost-effective small batch production and rapid iteration cycles without incremental investment.

For product development phases or limited series production, rapid prototyping with metal AM dramatically shortens time-to-market and reduces upfront costs.

Complex Geometries

When manufacturing parts with complex internal geometries, integrated features, or organic structures, metal 3D printing provides a clear cost advantage. CNC machining struggles or becomes prohibitively expensive for such designs due to the need for multi-axis machining, special tooling, or assembly of multiple components.

In sectors such as aerospace and power generation, metal AM enables designs that optimize cooling efficiency and reduce part count. Custom superalloy parts with internal channels or lattice structures are an excellent example of where metal 3D printing outperforms machining from both a cost and performance standpoint.

Short Lead Times

For applications requiring short lead times, metal 3D printing offers unmatched flexibility. Parts can be printed, post-processed, and delivered in as little as 3 to 7 days, while CNC machining, particularly when involving complex setups, often requires significantly longer lead times.

This makes metal AM a preferred choice for time-sensitive programs, emergency replacement parts, or early-stage product development where speed is critical to market success.

When is CNC Machining More Cost-Effective?

High Volume Production

CNC machining becomes more cost-effective as production volume increases. Once the initial setup and programming are completed, the marginal cost per part decreases significantly for high-volume production runs. For orders exceeding 1,000 units, CNC machining often outperforms metal 3D printing in cost per part due to faster cycle times and optimized material purchasing.

Additionally, automation with multi-axis CNC machines and pallet changers enables continuous, unattended machining, further driving down per-unit costs.

Tight Tolerance Parts

When applications demand extremely tight tolerances—typically ±0.01 mm or better—CNC machining remains the preferred process. For example, many components used in the medical and healthcare industries, such as surgical instruments and orthopedic implants, must meet rigorous dimensional and surface finish standards that are best achieved through precision machining.

While metal 3D printing can produce near-net-shape parts, additional machining is often required to achieve such fine tolerances, which adds cost and time. For parts where tolerance is the primary driver, CNC machining is more cost-efficient.

Standard Geometries and Materials

For parts with standard geometries—such as flat plates, shafts, or simple prismatic shapes—CNC machining is typically more cost-effective. These designs can be machined rapidly from stock material with minimal waste and tooling complexity.

Common materials like carbon steel, aluminum, and standard stainless steels are widely available in billet form and are highly optimized for CNC processes. In such cases, CNC machining delivers faster throughput and lower cost than printing.

Conclusion: How to Choose the Right Process

Selecting between metal 3D printing and CNC machining depends on multiple factors—design complexity, production volume, required tolerances, material type, and lead time. For projects involving intricate geometries, low to medium volumes, or fast turnaround needs, metal additive manufacturing offers clear cost and design advantages.

Conversely, for high-volume production, tight tolerance components, or simple geometries, CNC machining remains the most cost-effective solution. Many manufacturers are now adopting a hybrid approach, combining the strengths of both processes to optimize performance and cost.

Emerging applications, such as custom stainless steel 3D printing, continue to push the boundaries of what is achievable with additive technologies. Ultimately, understanding the trade-offs and matching the right process to your project’s specific requirements ensures the best return on investment and product performance.