3D Printed Metal vs Forged Metal: Strength Comparison for Custom Industrial Components

Introduction

In modern industrial manufacturing, the demand for high-strength, high-performance metal components is continuously increasing. Among various metal fabrication technologies, 3D printed metal and forged metal have emerged as two key options for producing custom industrial components.

3D metal printing provides unmatched design flexibility, enabling engineers to create complex geometries that are impossible with traditional methods. In contrast, forged metal delivers exceptional mechanical integrity through grain refinement and deformation processes. Each approach offers distinct advantages, particularly in strength-critical applications.

This article presents a technical comparison between 3D printed and forged metals from a strength perspective, helping engineers make informed decisions for their projects. Leveraging advanced 3D Printing Service platforms and an extensive selection of 3D printing materials, modern manufacturers can now tailor metal components to precise industrial requirements.

Overview of 3D Printed Metal and Forged Metal Processes

3D Printed Metal Process Overview

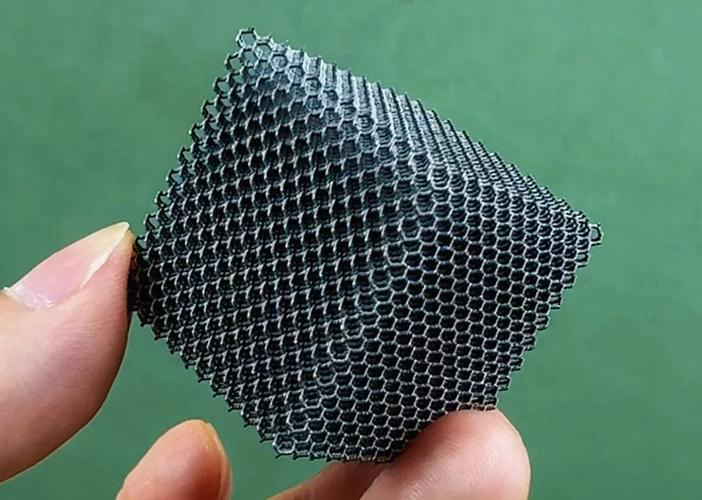

3D printed metal parts are produced layer by layer using various additive manufacturing processes. This allows for the creation of complex geometries, internal channels, and lightweight lattice structures.

The most widely used technique is Powder Bed Fusion (PBF), where a laser or electron beam selectively melts layers of fine metal powder to form dense components. It delivers excellent accuracy and mechanical performance, making it suitable for aerospace, medical, and tooling applications.

Another important process is Directed Energy Deposition (DED), which uses a focused energy source to melt metal feedstock (either powder or wire) during deposition. DED is ideal for manufacturing large-scale parts, component repairs, and hybrid builds where complex structures are combined with forged substrates.

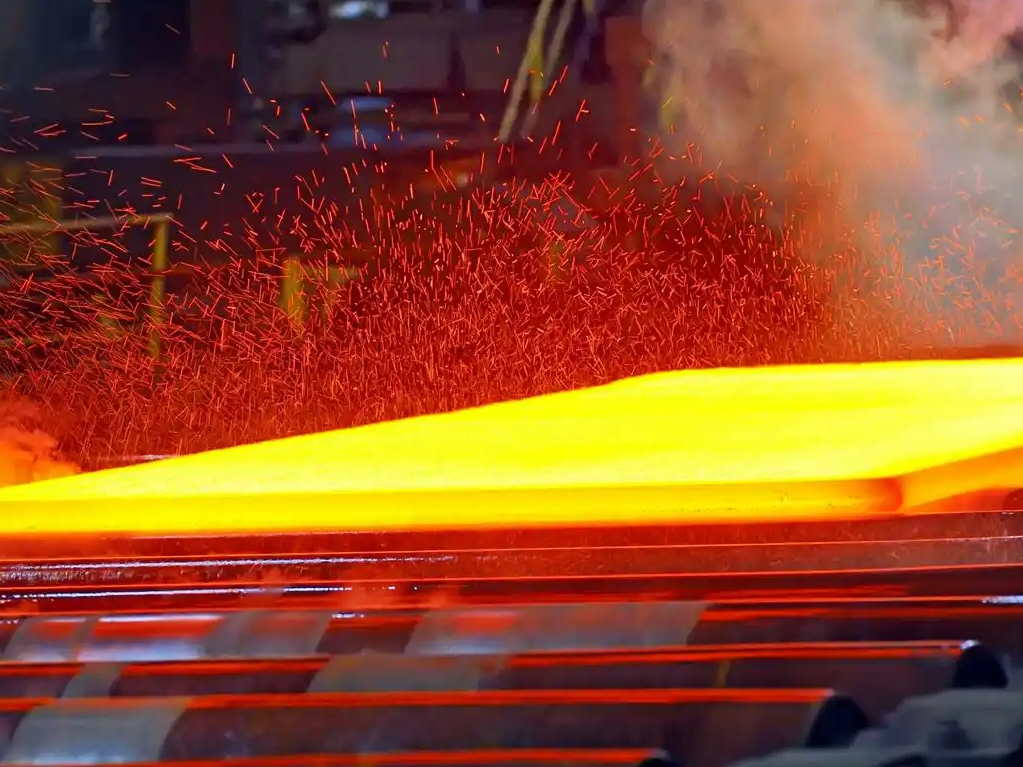

Forged Metal Process Overview

Forged metal components are produced by applying compressive forces to deform metal billets into the desired shape. Common techniques include open-die forging, closed-die forging, and precision forging. During forging, the material undergoes plastic deformation that refines the grain structure, improving strength, fatigue resistance, and impact toughness.

Forging is typically used for structural parts that require superior mechanical properties, such as aircraft landing gear, automotive drivetrain components, and energy sector hardware. However, forging is limited in its ability to produce intricate internal geometries or lightweight lattice structures, which are strengths of 3D printed metal processes.

Material Strength Comparison: 3D Printed Metal vs Forged Metal

Tensile Strength and Yield Strength

Tensile strength and yield strength are fundamental metrics for evaluating load-bearing capability. Forged metals typically exhibit superior strength due to their dense, directionally aligned grain structure. The deformation during forging breaks up inclusions and eliminates voids, resulting in homogeneous material with high strength.

For example, forged Ti-6Al-4V achieves tensile strengths up to 1000 MPa with yield strengths around 900 MPa. In contrast, 3D printed Ti-6Al-4V via Powder Bed Fusion can reach tensile strengths of 950–1000 MPa and yield strengths around 850–900 MPa, provided optimized printing parameters and post-processing are applied. The slight reduction in strength is attributed to process-induced porosity and residual microstructural variations in additive builds.

In stainless steel alloys, forged SUS316L typically delivers tensile strengths of 570–620 MPa, while high-quality 3D printed counterparts achieve similar values (~600 MPa), with proper densification and heat treatment. Thus, with advanced processes, 3D printed metals can approach the strength of forged equivalents.

Fatigue Strength and Fracture Toughness

Fatigue performance is more sensitive to surface quality, residual stresses, and internal defects. Forged metals, with their refined grain structure and absence of layer interfaces, exhibit superior fatigue life. They can withstand millions of cycles under fluctuating loads without crack initiation.

3D printed metals inherently have layer-induced anisotropy and potential for micro-voids or lack-of-fusion defects, which can act as fatigue initiation sites. However, through process optimization and Heat Treatment, fatigue life can be significantly enhanced. Stress-relief heat treatments, hot isostatic pressing (HIP), and surface finishing can close internal porosity and smooth surface roughness, improving fatigue resistance.

Fracture toughness also favors forged metals, especially in safety-critical components where crack propagation resistance is vital. Advanced post-processing allows 3D printed metals to achieve competitive fracture toughness for many non-safety-critical industrial applications.

Residual Stresses and Defects

Forged components benefit from uniform residual stress distribution due to mechanical deformation and controlled cooling. This provides inherent dimensional stability.

In contrast, 3D printed metals are prone to thermal gradients during layer-by-layer processing, which induce residual tensile stresses. If not properly managed, these stresses can lead to part distortion or cracking. Post-print heat treatment is essential to relieve residual stresses and stabilize the printed structure.

Defects such as porosity, inclusions, or incomplete fusion can occur in both forged and printed metals, but modern 3D printing technologies—combined with in-situ monitoring and rigorous post-processing—can achieve >99.9% density, rivaling that of forged components.

Post-Processing Impact on Strength

CNC Machining for Dimensional Precision

CNC Machining plays a critical role in achieving dimensional accuracy and surface finish on 3D printed metal parts. Additive processes inherently produce surface roughness and slight dimensional deviations due to layer-based deposition.

Post-process CNC machining refines critical surfaces, removes surface defects, and achieves the tight tolerances required for assembly and functional interfaces. Additionally, machining can eliminate surface-connected porosity, reducing fatigue initiation sites and improving overall strength and reliability.

For complex geometries produced via Powder Bed Fusion or Directed Energy Deposition, hybrid manufacturing—combining 3D printing with CNC machining—offers optimal structural integrity and precision.

Surface Treatment for Enhanced Wear and Corrosion Resistance

Surface Treatment further enhances the mechanical properties of metal components, particularly in terms of wear resistance, corrosion protection, and fatigue performance.

Common treatments include anodizing, nitriding, PVD coatings, and polishing. For 3D printed stainless steel or titanium parts, surface treatments can smooth micro-roughness, seal surface porosity, and introduce compressive surface stresses that improve fatigue life.

In corrosive environments, applying protective coatings extends component lifespan and maintains structural integrity under harsh conditions. Surface treatments are equally valuable for forged parts, offering tailored surface properties based on application needs.

Hot Isostatic Pressing (HIP) for Density and Mechanical Properties

Hot Isostatic Pressing (HIP) is a highly effective post-process for improving the density and mechanical properties of 3D printed metal components. The process applies high pressure and elevated temperature in an inert gas environment, eliminating internal porosity and improving interlayer bonding.

HIP-treated 3D printed metals can achieve mechanical properties—tensile strength, fatigue resistance, and fracture toughness—that closely match or exceed those of forged equivalents. This makes HIP a vital post-process for aerospace, medical, and critical industrial components where reliability is paramount.

Through the combined use of CNC machining, surface treatment, and HIP, 3D printed metal parts can be engineered to meet the most demanding industrial strength and durability requirements.

Application-Specific Strength Considerations

Aerospace and Aviation

In the Aerospace and Aviation sector, weight reduction, fatigue performance, and high-temperature strength are paramount. Forged metals such as titanium and superalloys have long been used for flight-critical components due to their proven reliability and superior fatigue resistance.

However, 3D printed metals are increasingly adopted for non-flight-critical and optimized structural components. The ability to produce lightweight lattice structures and complex geometries offers significant weight savings. When combined with post-processing such as HIP and surface finishing, 3D printed aerospace parts can meet stringent mechanical performance standards for satellite components, brackets, and heat exchangers.

Automotive and Industrial Components

In Automotive and industrial applications, strength-to-weight ratio, wear resistance, and production scalability are key considerations. Forged steel and aluminum alloys remain dominant in critical load-bearing components like crankshafts, suspension arms, and drivetrain gears due to their high strength and cost efficiency in mass production.

3D printed metals, meanwhile, excel in low-to-medium volume production of complex, weight-optimized components. They are ideal for motorsports, custom performance parts, and prototyping of advanced designs. For example, 3D printed aluminum and titanium components with optimized topologies are used in racing and high-performance vehicles to achieve both strength and weight reduction.

Energy Sector and High-Temperature Applications

In the Energy and Power industry, components must endure high mechanical loads, cyclic stresses, and extreme temperatures. Forged superalloys continue to dominate turbine discs, shafts, and high-pressure valves due to their unmatched fatigue resistance and thermal stability.

3D printed metals are rapidly gaining ground for complex heat exchangers, turbine blades with internal cooling channels, and the repair of worn components. Advanced materials like Inconel 718 and Hastelloy, combined with optimized printing and post-processing, deliver components with excellent high-temperature strength and corrosion resistance, meeting the demanding needs of modern energy systems.

Conclusion

Both 3D printed and forged metals offer distinct strengths that serve different industrial needs. Forged metals provide superior fatigue resistance, fracture toughness, and reliability in highly stressed structural components. Conversely, 3D printed metals deliver unparalleled design freedom, enabling lightweight geometries, functional integration, and rapid prototyping.

Through advanced post-processing, such as CNC machining, heat treatment, surface treatment, and HIP, 3D printed metals can approach or match the mechanical performance of forged components in many applications.

Ultimately, material selection and process choice should be guided by application-specific requirements: critical load-bearing aerospace and energy components may favor forging, while automotive, custom industrial parts, and complex geometries benefit greatly from metal additive manufacturing.

By understanding the comparative strengths of these technologies, engineers can make informed decisions and leverage the right process to optimize component performance for modern industrial challenges.