¿Qué materiales son los más adecuados para el mecanizado EDM?

Tabla de contenidos

What Materials Are Best Suited for EDM Machining?

Overview of EDM Material Suitability

Best Material Categories for EDM Machining

Customer-Oriented Solutions and Services

Español / ES

Título

¿Qué materiales son los más adecuados para el mecanizado EDM?

Descripción

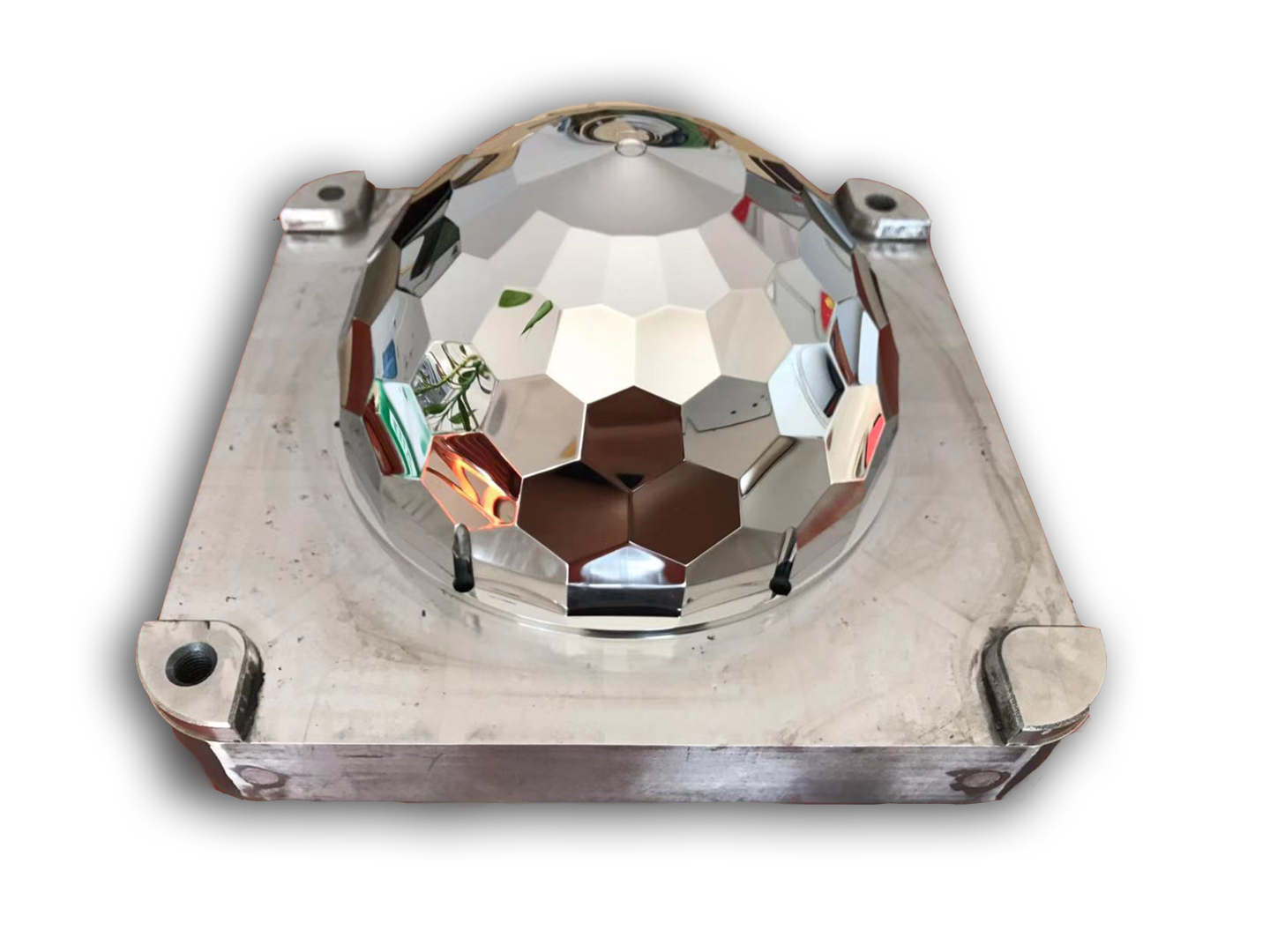

El EDM es ideal para mecanizar aceros para herramientas, titanio, superaleaciones y aceros inoxidables con alta precisión y sin deformación, perfecto para aplicaciones aeroespaciales, médicas y de moldes.

Palabras clave

compatibilidad de materiales EDM, mecanizado EDM de acero herramienta, corte EDM de titanio, erosión de Inconel, piezas EDM de acero endurecido, mecanizado EDM de aleaciones de cobre, superaleaciones de alta precisión, conformado metálico sin contacto

Related Blogs

Suscríbase para recibir consejos de diseño y fabricación de expertos en su bandeja de entrada.

Compartir esta publicación: