Copper CuCr1Zr

Introduction to Copper CuCr1Zr for 3D Printing

Copper CuCr1Zr (UNS C18150) is a high-performance precipitation-hardened copper alloy containing 0.6–1.2% chromium and 0.03–0.3% zirconium. It combines excellent thermal conductivity (~320 W/m·K), electrical conductivity (~80–90% IACS), and superior strength (~500 MPa), making it ideal for tooling, welding electrodes, and aerospace thermal structures.

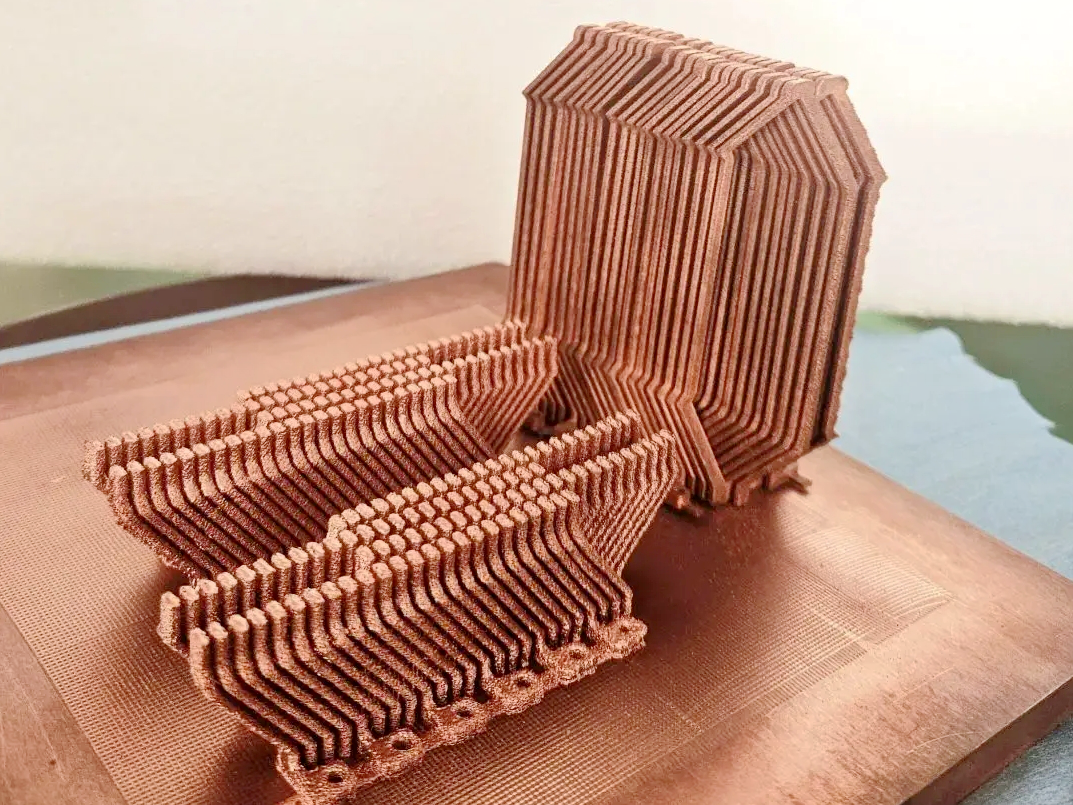

Through Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), CuCr1Zr delivers excellent print quality with dimensional accuracy ±0.05 mm, while maintaining key mechanical and thermal properties for demanding industrial use.

International Equivalent Grades of Copper CuCr1Zr

Country | Grade Number | Other Names/Titles |

|---|---|---|

USA | C18150 | RWMA Class 2 |

Europe | CW106C | EN 12163 |

China | QCr0.5-0.2 | GB/T 5231 |

Japan | C18080 | JIS H3100 |

Comprehensive Properties of Copper CuCr1Zr

Property Category | Property | Value |

|---|---|---|

Physical | Density | 8.89 g/cm³ |

Melting Point | 1,080°C | |

Thermal Conductivity | ~320 W/m·K | |

Electrical Conductivity | 80–90% IACS | |

Chemical | Copper (Cu) | Balance |

Chromium (Cr) | 0.6–1.2% | |

Zirconium (Zr) | 0.03–0.3% | |

Mechanical | Tensile Strength (aged) | 480–550 MPa |

Yield Strength (aged) | 400–500 MPa | |

Elongation | 10–20% | |

Hardness (Vickers HV) | 120–160 HV |

Suitable 3D Printing Processes for Copper CuCr1Zr

Process | Typical Density Achieved | Surface Roughness (Ra) | Dimensional Accuracy | Application Highlights |

|---|---|---|---|---|

≥99% | 10–14 µm | ±0.05 mm | Suitable for fine cooling channels, electrode inserts, and compact thermal parts | |

≥99.5% | 6–10 µm | ±0.05 mm | Ideal for high-strength copper molds, RF tooling, and aerospace heat transfer components |

Selection Criteria for CuCr1Zr 3D Printing Processes

Mechanical Strength Needs: Aged CuCr1Zr provides tensile strengths up to 550 MPa, suitable for load-bearing thermal tooling and high-cycle production parts.

Thermal and Electrical Requirements: With 80–90% IACS conductivity, it is perfect for welding electrodes, heat sinks, and power-carrying connectors.

Complex Geometry Capabilities: SLM and DMLS support conformal cooling, lattice structures, and tight internal channels with fine features down to 0.4 mm.

Post-Processing Requirements: Age-hardening and machining are essential for final performance, ensuring strength, conductivity, and surface quality.

Essential Post-Processing Methods for CuCr1Zr 3D Printed Parts

Age Hardening: Aging at 460–480°C for 2–4 hours increases strength, hardness, and conductivity without sacrificing ductility.

CNC Machining: Precision finishing down to ±0.02 mm for mold inserts, cooling interfaces, and assembly features.

Polishing and Electropolishing: Improves surface finish to <0.8 µm Ra and enhances thermal contact and corrosion resistance.

Tumbling: Mechanical finishing used to smooth and deburr parts with complex geometries or dense internal features.

Challenges and Solutions in CuCr1Zr 3D Printing

Laser Absorption Efficiency: Standard IR lasers struggle with pure copper; optimized process parameters and powder composition improve melt pool stability.

Oxidation Sensitivity: Printing in an inert argon atmosphere ensures minimal oxide formation, preserving both conductivity and mechanical properties.

Shrinkage Control: Proper support design and heat-treatment simulation reduce dimensional distortion during cooling and aging stages.

Applications and Industry Case Studies

CuCr1Zr is extensively applied in:

Automotive: High-performance cooling blocks, spot welding electrodes, e-power connectors.

Mold & Tooling: Conformal cooling channels, mold cores, and copper inserts for improved cycle time.

Aerospace: Thermal management modules, avionics grounding lugs, heat spreaders.

Electronics: Connector pins, busbars, thermal vias, and RF tooling components.

Case Study: 3D printed CuCr1Zr cooling inserts with conformal channels improved cycle time by 35% in plastic injection tooling, while maintaining over 85% IACS conductivity post-aging.

Frequently Asked Questions (FAQs)

What is the typical strength and conductivity of 3D printed CuCr1Zr after aging?

Which industries benefit most from CuCr1Zr additive manufacturing?

How do you control oxidation and porosity during CuCr1Zr printing?

What surface finishing options are available for CuCr1Zr components?

How does CuCr1Zr compare to pure copper in high-stress applications?