Tool Steel D2

D2 3D Printing Materials Introduction

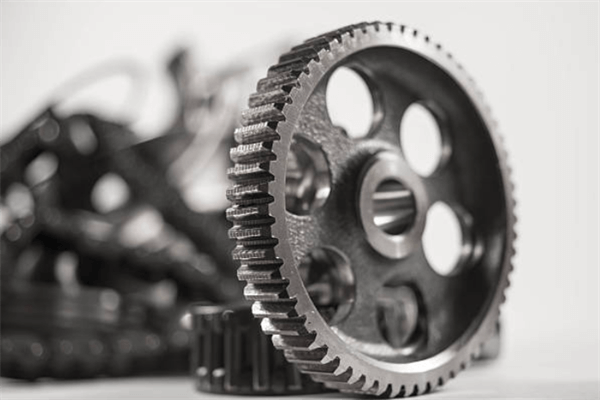

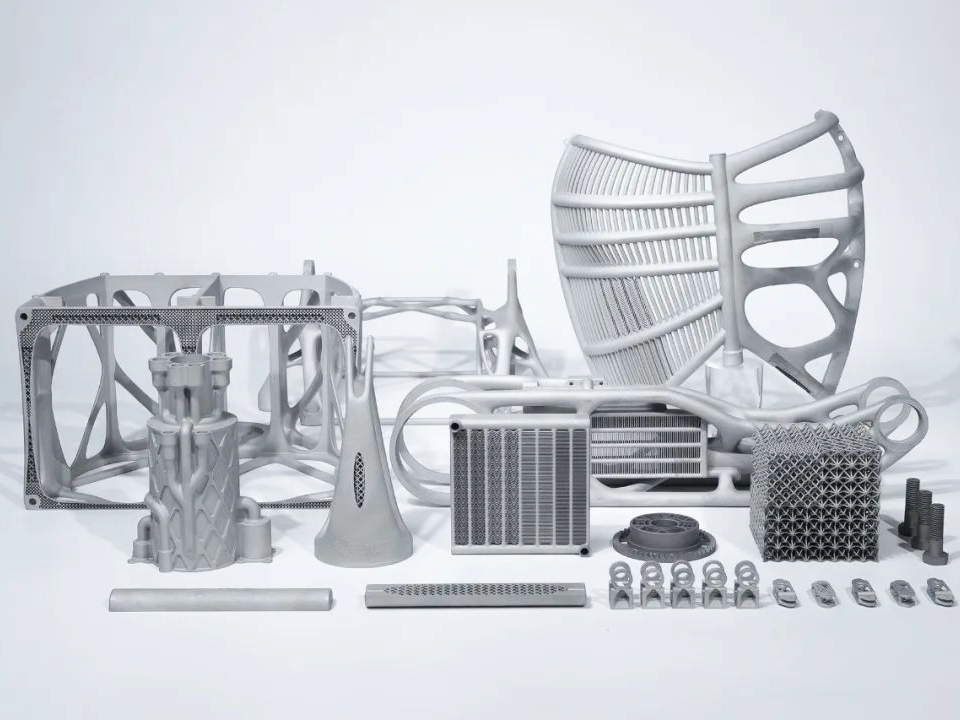

Tool Steel D2 is a high-carbon, high-chromium alloy known for excellent hardness, wear resistance, and dimensional stability. It is ideal for manufacturing cutting tools, dies, and molds used in high-load, abrasive environments. Through D2 3D printing, complex and durable tooling components can be produced with high precision, enabling performance improvements and material efficiency across automotive, aerospace, and industrial manufacturing sectors.

D2 Similar Grades Table

Country/Region | Standard | Grade or Designation | Synonyms |

|---|---|---|---|

USA | ASTM | D2 | Tool Steel D2, DIN 1.2379 |

UNS | Unified | T30402 | - |

ISO | International | 1.2379 | X155CrMoV12 |

China | GB/T | Cr12MoV | Cr12MoV |

Germany | DIN/W.Nr. | 1.2379 | - |

D2 Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 7.85 g/cm³ |

Melting Point | 1425°C | |

Thermal Conductivity (100°C) | 25.0 W/(m·K) | |

Electrical Resistivity | 60 µΩ·cm | |

Chemical Composition (%) | Carbon (C) | 1.50–1.60 |

Chromium (Cr) | 11.0–13.0 | |

Molybdenum (Mo) | 0.70–1.20 | |

Vanadium (V) | 0.90–1.20 | |

Iron (Fe) | Balance | |

Mechanical Properties | Tensile Strength | 1080 MPa |

Yield Strength (0.2%) | 850 MPa | |

Elongation at Break | 12% | |

Hardness (HRC) | 55–62 HRC | |

Modulus of Elasticity | 210 GPa |

3D Printing Technology of D2

Tool Steel D2 can be 3D printed using technologies such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These methods ensure high precision, excellent surface finish, and superior mechanical properties suitable for tooling applications.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

SLM | ±0.05–0.1 mm | Excellent | Excellent | Tooling, Dies, Cutting Tools |

DMLS | ±0.05–0.1 mm | Very Good | Excellent | Aerospace, Automotive Components |

EBM | ±0.1–0.3 mm | Good | Excellent | Complex Tooling, Molds |

D2 3D Printing Process Selection Principles

SLM is ideal for high-precision tooling parts, achieving superior part density (>99%) and uniform mechanical properties, ensuring excellent wear resistance in tooling applications. DMLS allows the creation of complex geometries, internal lattice structures, and part consolidation, improving tool longevity and reducing material waste in production environments. EBM is ideal for manufacturing large, tough tooling parts, providing high mechanical properties with better tolerance to temperature changes during operation.

D2 3D Printing Key Challenges and Solutions

Residual stress and warping are common challenges in printing Tool Steel D2. Post-processing heat treatment at 1100–1150°C is critical for relieving these stresses and ensuring dimensional stability. CNC machining is often necessary for achieving the final tolerances and surface finishes, especially for tooling applications where smooth finishes and precise geometries are required. Another challenge is the relatively high hardness of D2, which can make post-processing, such as electropolishing, more difficult. Utilizing precise machining or abrasive finishing techniques can help address this issue. Passivation is often applied to enhance corrosion resistance, especially in tools used in chemical or high-wear environments.

Typical Post-Processing for D2 3D Printed Parts

Annealing Heat Treatment at 1100–1150°C restores hardness, relieves stress, and ensures dimensional accuracy, critical for maintaining tool performance. CNC Machining achieves high tolerance for cutting edges, hole features, and sharp geometries, which are vital for tooling components used in precise applications. Electropolishing is used to enhance surface smoothness and remove any imperfections, ensuring cleanability and corrosion resistance, especially for tooling components in contact with abrasive materials. Passivation enhances corrosion resistance by creating a stable oxide layer, ensuring that D2 tools perform well in environments with high temperatures or chemical exposure.

Industry Application Scenarios and Cases

D2 is widely used in:

Tooling: Punches, dies, and cutting tools in automotive, aerospace, and manufacturing industries where wear resistance is essential.

Molds: Injection molds, extrusion dies, and stamping dies requiring high hardness and toughness.

Machining: End mills, drills, and other cutting tools used in high-precision applications with high wear resistance. A case study from the automotive industry featured D2 3D printed dies that exhibited superior durability and extended tool life by 30% over traditionally manufactured dies.

FAQs

What is the maximum hardness achievable for 3D printed D2 tool steel after heat treatment?

Can D2 tool steel 3D printed parts replace traditional CNC-machined dies in high-volume stamping applications?

What are the ideal post-processing steps for improving D2 part performance and dimensional accuracy?

Which industries benefit most from D2 3D printing in terms of cost or lead time?

Is D2 suitable for injection mold applications requiring abrasion resistance and long cycle durability?