What Are The 3D Printing Technologies Used for Carbon Steel Parts Additive Manufacturing?

Carbon steel, known for its strength, durability, and versatility, is widely used in automotive, construction, energy, and manufacturing industries. 3D printing technologies have revolutionized carbon steel production, creating complex geometries, reducing material waste, and faster production times. This blog explores the primary 3D printing technologies used for carbon steel parts, focusing on materials, applications, and specific advantages of each technology.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is a widely used powder-bed fusion technology for producing carbon steel parts. A laser selectively fuses carbon steel powder layer by layer, creating solid parts with high density and mechanical strength.

Materials:

Carbon Steel 1018: Known for its excellent machinability and good tensile strength (approximately 440 MPa), it is commonly used in automotive and structural applications.

Carbon Steel 4340: Offers high tensile strength (up to 1,100 MPa) and toughness, ideal for heavy-duty applications such as automotive and aerospace.

Carbon Steel 1020: Provides good weldability and is used in applications requiring low to moderate strength.

Applications:

Automotive: Manufacturing of engine parts, transmission components, and structural parts.

Construction: Used for producing durable and strong parts for building structures.

Manufacturing: Ideal for creating custom parts, such as gears, shafts, and brackets.

Benefits:

High Density: DMLS produces parts with up to 99.9% density, providing excellent mechanical properties.

Complex Geometries: Can create parts with internal structures, lightweight designs, and intricate features.

Minimal Post-Processing: Achieves high precision, reducing the need for additional finishing steps.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) uses a laser to fully melt carbon steel powder, forming fully dense parts with superior mechanical properties. This method is ideal for producing high-strength components for demanding applications.

Materials:

Carbon Steel 4340: Offers high tensile strength (1,100 MPa) and is suitable for aerospace, automotive, and heavy machinery applications.

Carbon Steel 1018: Ideal for low-stress applications requiring good machinability and moderate strength.

Applications:

Automotive: Production of high-strength automotive parts such as engine blocks and chassis components.

Aerospace: Manufacturing of critical components that require high tensile and fatigue resistance.

Energy: Used in power generation systems for producing robust parts that can withstand high temperatures and mechanical stresses.

Benefits:

Full Density: Achieves 100% material density, ensuring parts have superior strength and durability.

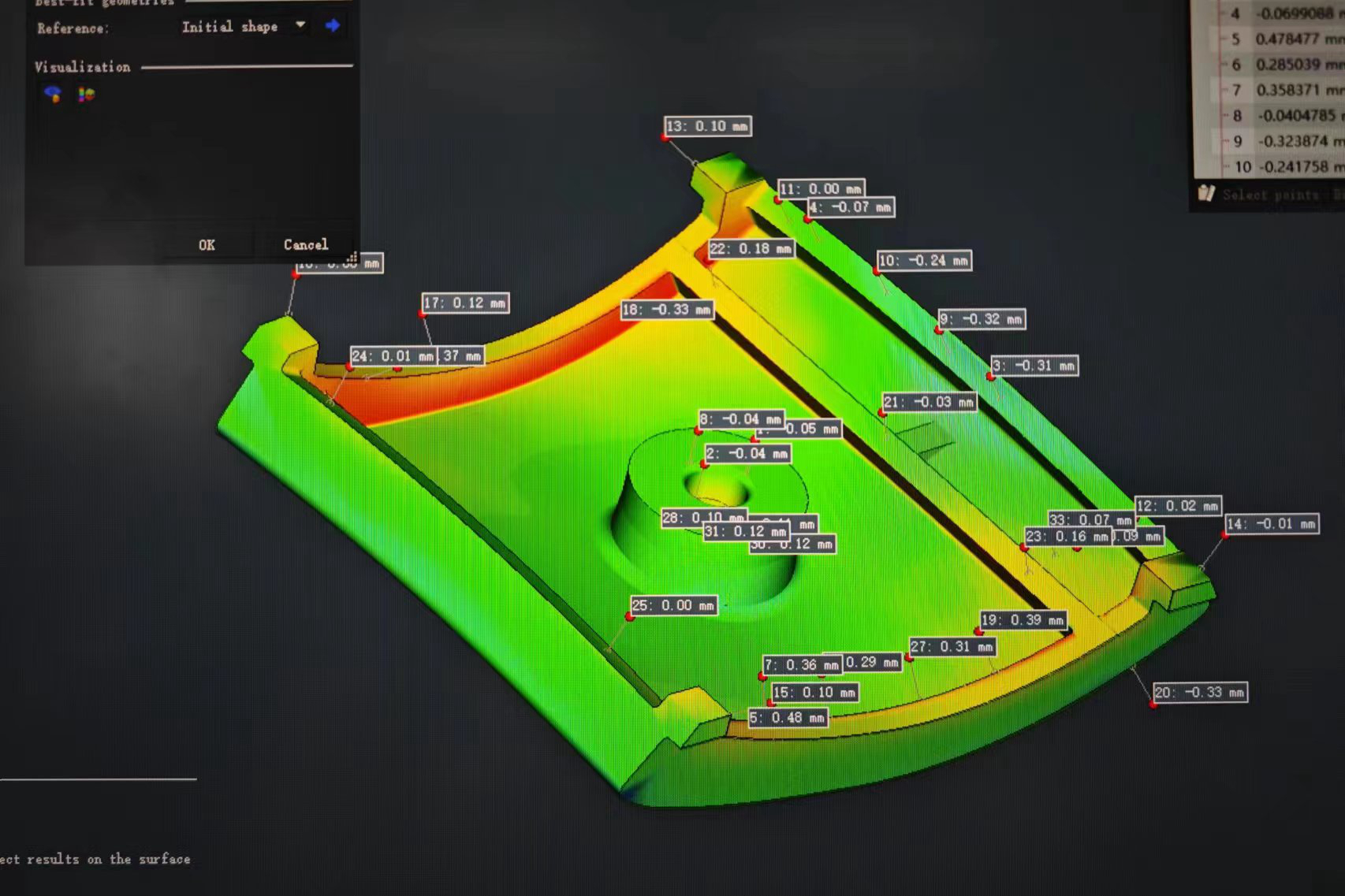

Precision: Offers high resolution with tight tolerances (±0.05 mm), ideal for producing complex and intricate designs.

Customization: Allows for the production of highly customized parts with tailored properties for specific applications.

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) is a high-performance additive manufacturing technology that uses an electron beam to melt carbon steel powder in a vacuum. This process produces high-density parts with excellent mechanical properties, which is ideal for extreme environments.

Materials:

Carbon Steel 4340: Known for its high strength (up to 1,100 MPa) and toughness, used in aerospace and energy industries.

Carbon Steel 1020: Provides good weldability and is used in structural applications with moderate mechanical requirements.

Applications:

Aerospace: EBM is used to manufacture complex turbine components and structural parts that require high strength and resistance to heat.

Energy: Components for power generation systems must endure high pressure and temperature.

Medical: Custom implants and prosthetics that require high strength and biocompatibility.

Benefits:

High Strength: EBM produces parts with minimal porosity, ensuring excellent mechanical properties.

Minimal Porosity: The vacuum environment ensures low porosity, enhancing the durability of parts.

Low-Volume Production: Ideal for producing complex stainless steel parts in low- to medium-volume runs.

Binder Jetting for Carbon Steel Parts

Binder Jetting is a cost-effective 3D printing technology that uses a liquid binder to fuse carbon steel powder selectively. The printed parts are then sintered to achieve full density.

Materials:

Carbon Steel 1018: A general-purpose material used for prototyping and low-stress applications.

Carbon Steel 4340: A high-strength material suitable for applications requiring toughness and resistance to wear.

Applications:

Prototyping: Binder jetting is ideal for producing quick prototypes and design iterations before moving to full production.

Casting Patterns: Used for producing casting molds, reducing material waste and improving casting efficiency.

Benefits:

Cost-Effective: Affordable for producing prototypes and small batches.

Fast Production: Capable of producing parts quickly, ideal for short lead times and low-volume production.

Complex Geometries: Suitable for creating intricate, lightweight designs with minimal material waste.

Conclusion

The 3D printing technologies used for carbon steel parts, including DMLS, SLM, EBM, and Binder Jetting, provide significant advantages for producing high-performance components across automotive, aerospace, energy, and manufacturing industries. Whether producing strong, lightweight engine components with Carbon Steel 4340 or creating cost-effective prototypes with Carbon Steel 1018, these technologies offer design flexibility, material efficiency, and reduced production times.

FAQs

Which 3D printing technology is best for carbon steel parts in automotive applications?

What carbon steel materials are commonly used in Selective Laser Melting (SLM)?

How does Electron Beam Melting (EBM) benefit carbon steel parts for aerospace applications?

Can Binder Jetting produce carbon steel parts, and what are its advantages?

What is the role of carbon steel alloys in additive manufacturing for energy sector components?