What carbon steel materials are commonly used in Selective Laser Melting (SLM)?

What Carbon Steel Materials Are Commonly Used in Selective Laser Melting (SLM)?

Overview

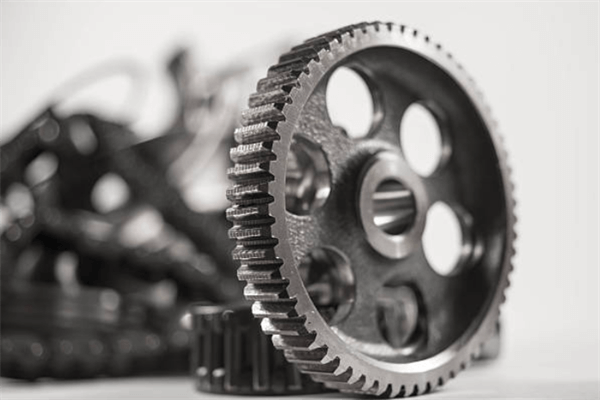

Selective Laser Melting (SLM) is capable of producing fully dense carbon steel parts with excellent strength, wear resistance, and toughness, making it a suitable technology for high-performance industrial and automotive applications. Common carbon steel grades processed via SLM include alloy steels, tool steels, and case-hardening steels, each selected based on mechanical and thermal performance requirements.

Common Carbon Steel Grades for SLM

AISI 4140

A chromium-molybdenum alloy steel known for its high fatigue strength and good machinability.

Tensile strength: ~950–1100 MPa (after heat treatment)

Applications: Suspension arms, transmission shafts, gear housings

AISI 4130

A versatile low-alloy steel with high impact strength and good weldability.

Tensile strength: ~850 MPa (heat treated)

Applications: Roll cages, brackets, linkages, aircraft fittings

Tool Steel D2

A high-carbon, high-chromium tool steel with excellent wear resistance and dimensional stability.

Hardness: Up to 60 HRC after heat treatment

Applications: Dies, cutting tools, forming molds, injection tooling

20MnCr5

A case-hardening steel with excellent toughness and surface hardness post-carburizing.

Core toughness with surface hardness > 58 HRC

Applications: Gears, drive shafts, camshafts

Tool Steel H13

A chromium hot-work tool steel offering excellent thermal fatigue resistance.

Common in high-temperature tooling applications

Applications: Die casting molds, hot stamping dies, extrusion tooling

Customer-Oriented Solutions and Services

We offer complete carbon steel part production using SLM:

3D Printing Technologies:

Access our Carbon Steel 3D Printing capabilities using SLM for parts requiring strength, wear resistance, and heat treatment compatibility.

Material Options:

Choose from high-performance carbon steel grades like AISI 4140, Tool Steel D2, and 20MnCr5 tailored for tooling, drivetrain, and structural components.

Post-Processing Support:

Enhance properties through heat treatment, CNC machining, and surface treatment for end-use readiness.