What Metals Are Suitable for 3D Printing? Guide to Material Selection for Custom Parts

Introduction

Metal additive manufacturing is revolutionizing custom part production. From aerospace to medical applications, metal 3D printing enables the creation of complex geometries and functional components that traditional methods cannot easily achieve. However, the success of a 3D-printed part heavily depends on selecting the right material.

This guide explores the key metals suitable for 3D printing and offers insights into selecting optimal materials for your application. Leveraging advanced 3D Printing Service platforms and an extensive portfolio of 3D printing materials, engineers can now produce precision parts with tailored properties, ensuring superior performance and reliability in demanding environments.

Overview of Metal 3D Printing Processes

Overview of Metal 3D Printing Processes

Metal 3D printing utilizes various additive manufacturing techniques to fabricate high-performance parts layer by layer. Each process offers distinct capabilities, allowing engineers to select the optimal method based on part geometry, material, and performance requirements.

Common 3D Printing Technologies for Metals

Powder Bed Fusion (PBF) is the most widely used process for metal 3D printing. It employs a high-energy laser or electron beam to selectively fuse fine metal powder, achieving excellent dimensional accuracy and mechanical properties. Technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM) fall under this category, making it ideal for aerospace, medical, and tooling applications.

Directed Energy Deposition (DED) uses a focused energy source (laser, electron beam, or plasma arc) to melt metal feedstock—either powder or wire—as it is deposited. DED excels at building large-scale parts and repairing existing components, often used in aerospace maintenance and energy sectors.

Binder Jetting is an emerging technology where a liquid binder selectively joins metal powder layers. The printed "green" parts undergo post-process sintering to achieve final density. Binder Jetting enables high-volume, cost-effective production of complex geometries, suitable for tooling, automotive, and consumer industries.

Advantages of Metal 3D Printing for Custom Parts

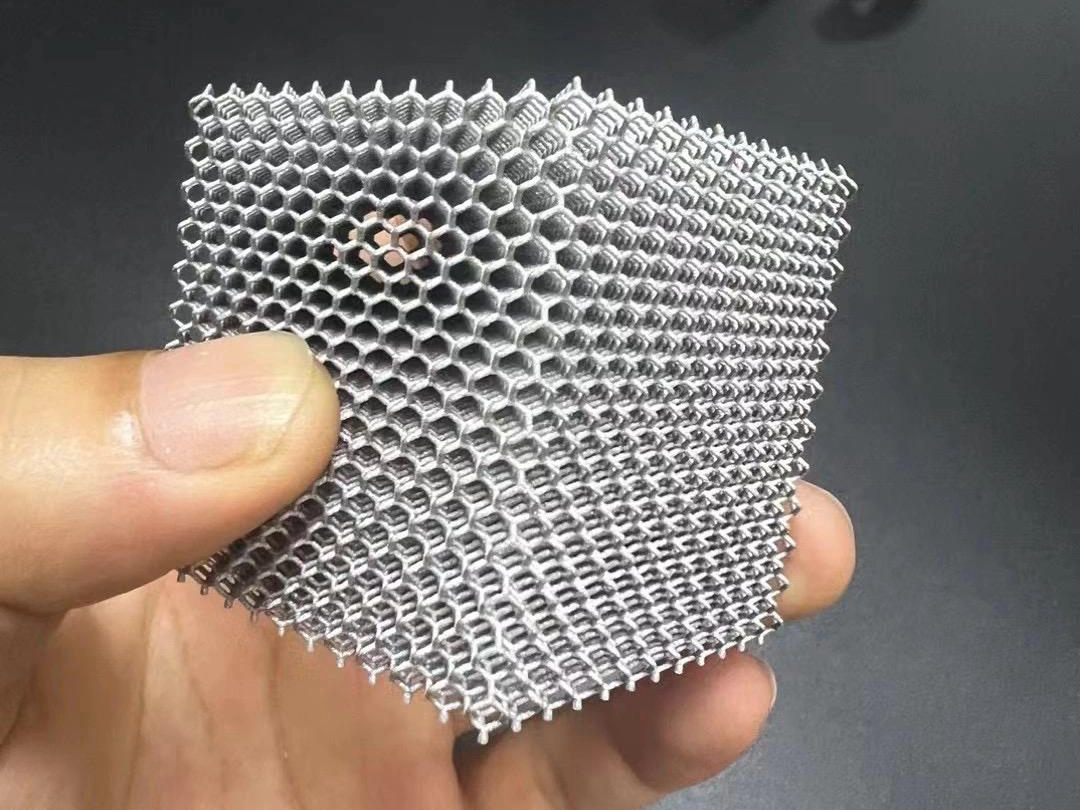

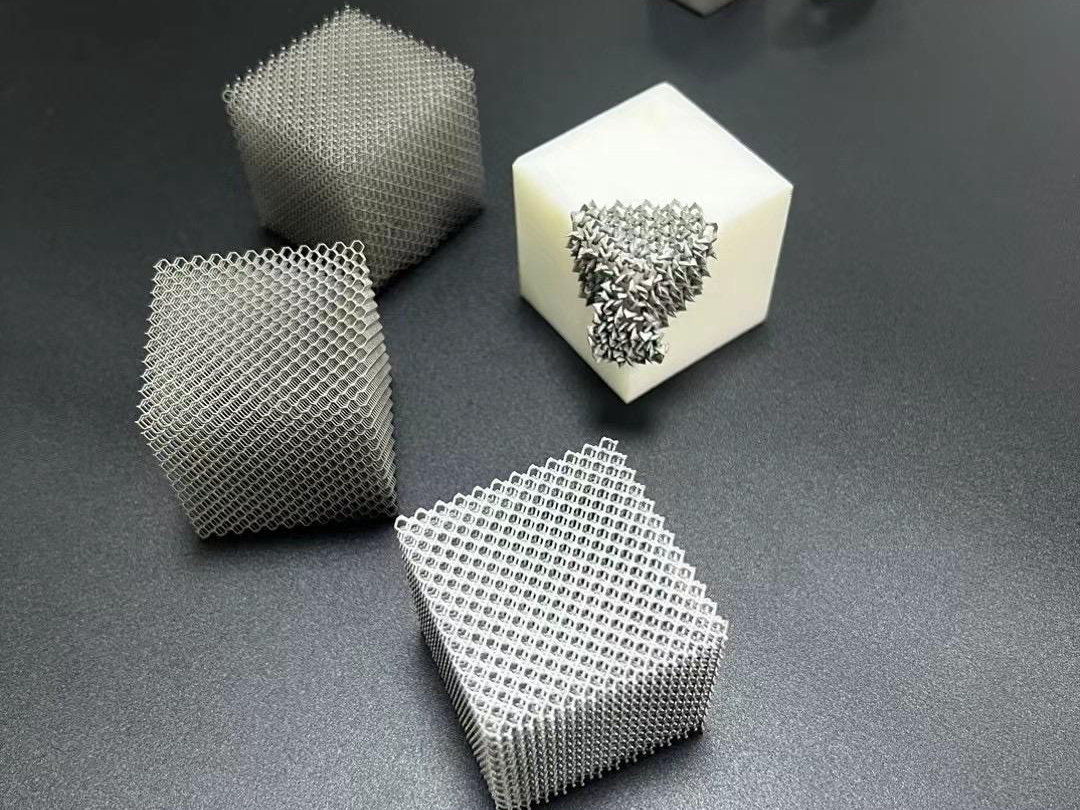

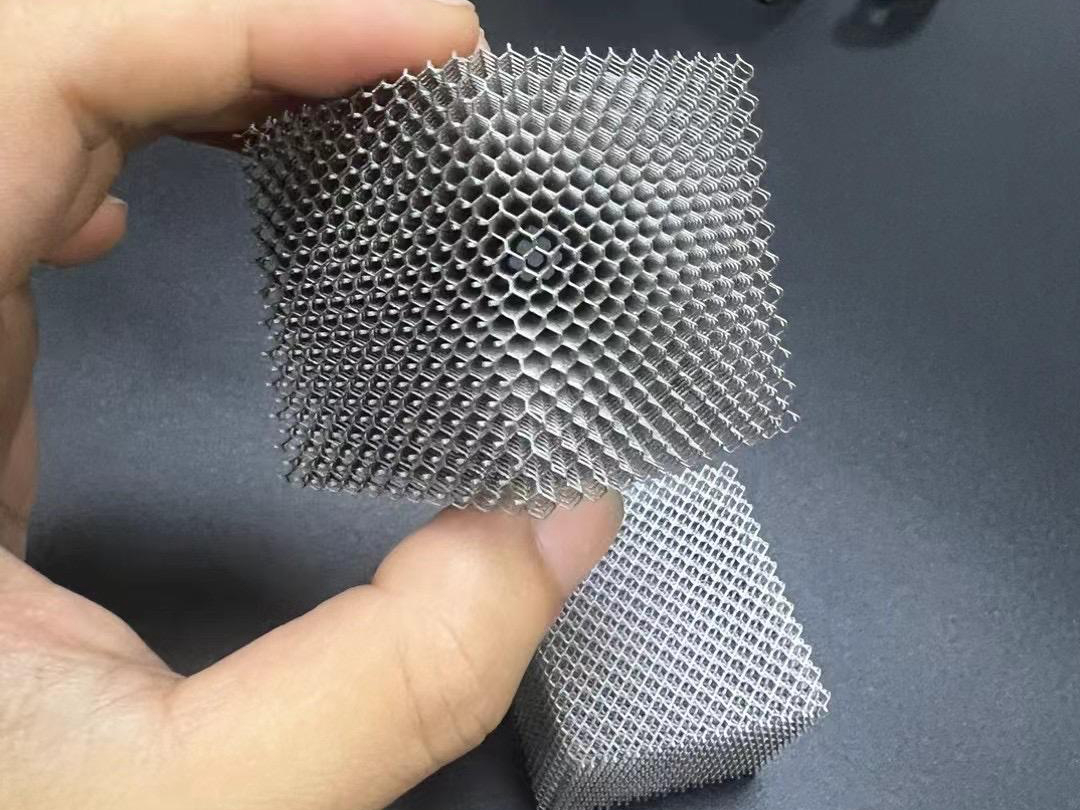

Metal 3D printing supports intricate internal structures, lightweight lattice designs, and functional integration, reducing assembly steps. It offers unmatched design freedom while maintaining high-performance standards, making it an indispensable solution for custom part manufacturing across various industries.

Common Metal Materials Suitable for 3D Printing

Material selection is fundamental to the success of any metal 3D printing project. The following are the most commonly used metals, each offering unique mechanical properties, printability, and application potential.

Superalloys

Superalloy 3D Printing enables the fabrication of parts with exceptional strength, corrosion resistance, and thermal stability. These materials are engineered for use in extreme environments, such as jet engines, gas turbines, and chemical processing equipment.

Among them, Inconel 718 is a preferred choice due to its excellent fatigue resistance, tensile strength, and high-temperature performance up to 700°C. It is widely used for turbine blades, aerospace components, and structural parts in energy systems.

Titanium Alloys

Titanium alloys are synonymous with strength-to-weight optimization and biocompatibility. Titanium 3D Printing is popular in aerospace, automotive, and medical applications.

Ti-6Al-4V (TC4) is the most utilized grade. It offers excellent corrosion resistance, outstanding fatigue strength, and superior mechanical properties while being approximately 40% lighter than steel. It is ideal for aircraft structures, medical implants, and racing components.

Stainless Steel

Stainless Steel 3D Printing provides a cost-effective solution for durable, corrosion-resistant parts with high mechanical performance. It is suitable for a wide range of applications, including automotive, industrial tooling, consumer products, and medical devices.

Stainless Steel SUS316L is an austenitic stainless steel with excellent corrosion resistance and good mechanical strength. It is widely used in marine, chemical processing, and medical equipment applications.

Carbon Steel

Carbon Steel 3D Printing enables the production of parts with high hardness, wear resistance, and toughness, making it an excellent choice for industrial tools and dies.

Tool Steel H13 is one of the most common tool steels for 3D printing. It maintains excellent strength and hardness at elevated temperatures, making it ideal for injection molds, die casting dies, and tooling inserts.

Copper and Copper Alloys

Copper Alloy 3D Printing is gaining traction for thermal management and electrical applications, thanks to copper’s excellent conductivity. These parts are increasingly used in electronics, automotive heat exchangers, and induction systems.

Copper C101, a high-purity grade, offers exceptional electrical conductivity (~101% IACS) and excellent thermal conductivity. It is suitable for busbars, RF components, heat exchangers, and industrial conductors.

Aluminum Alloys

Aluminum alloys combine lightweight characteristics with good mechanical strength and corrosion resistance. They are widely used in aerospace, automotive, and consumer electronics.

Aluminum AlSi10Mg is the most frequently used aluminum alloy in metal 3D printing. It features an excellent strength-to-weight ratio, high corrosion resistance, and good thermal conductivity. Typical applications include aerospace components, lightweight automotive parts, housings, and structural elements.

Key Considerations When Selecting Metals for 3D Printing

Choosing the right metal for a 3D printing project requires careful evaluation of several critical factors. The material must not only meet design specifications but also align with process capabilities and post-processing requirements to ensure final part quality and performance.

Mechanical Properties

Engineers should first assess the mechanical properties needed for the application, such as tensile strength, yield strength, fatigue resistance, hardness, and elongation. For example, aerospace components may require high strength-to-weight ratios, while tooling applications prioritize wear resistance and toughness. Material datasheets and testing should guide selection to ensure optimal performance in the intended environment.

Printability

Not all metals exhibit the same printability. Factors such as laser absorption, powder flowability, and susceptibility to cracking influence print quality and process stability. Some superalloys and titanium grades may require process optimization or specialized equipment to achieve consistent results. Additionally, geometry considerations like overhangs, thin walls, and internal channels may impact material choice.

Post-Processing Requirements

Post-processing is often essential to achieve the final desired properties and surface finish of metal 3D printed parts.

CNC Machining is frequently used to refine dimensional accuracy and surface finish, especially for mating surfaces and precision-critical features.

Heat Treatment improves mechanical properties such as strength, hardness, and ductility, and helps relieve residual stresses induced during printing.

Surface Treatment enhances corrosion resistance, wear resistance, and aesthetic appearance, depending on the application environment.

Considering these factors holistically allows engineers to select metals that not only print well but also meet the final performance and quality expectations of custom parts.

Conclusion

Metal 3D printing offers engineers unmatched flexibility in producing high-performance custom parts. By carefully selecting materials that align with design objectives, application demands, and post-processing needs, manufacturers can achieve optimal outcomes in terms of functionality, durability, and precision.

With a comprehensive understanding of available metal options—from superalloys and titanium to stainless steel, carbon steel, copper, and aluminum—engineers are well-equipped to drive innovation across aerospace, automotive, medical, and industrial sectors. Thoughtful material selection remains the foundation of successful metal additive manufacturing.