20MnCr5

Introduction to 20MnCr5 for 3D Printing

20MnCr5 is a low-alloy, case-hardening steel comprising approximately 0.17-0.22% carbon, 1.10-1.40% manganese, and 1.00-1.30% chromium. Renowned for excellent case-hardening properties achieving surface hardness of 60-62 HRC and a tensile strength around 980 MPa, it is widely utilized for high-wear automotive components, industrial gears, and precision mechanical assemblies.

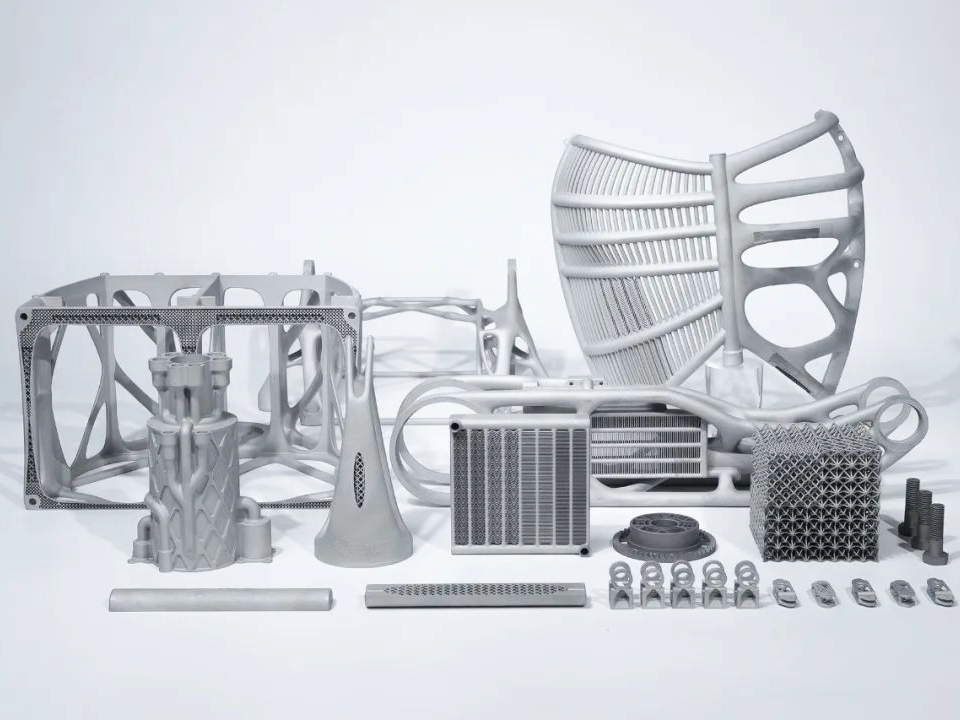

Advanced 3D printing technologies like Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) enable 20MnCr5 to produce precise geometries, intricate features, and dimensional tolerances within ±0.05 mm, satisfying stringent industrial requirements for custom printed parts.

International Equivalent Grades of 20MnCr5

Country | Grade Number | Other Names/Titles |

|---|---|---|

Germany | 1.7147 | DIN 20MnCr5 |

USA | SAE 5120 | UNS G51200 |

China | 20CrMn | GB/T 3077 |

Japan | SMnC420H | JIS G4052 |

UK | 805M20 | BS970 |

Comprehensive Properties of 20MnCr5

Property Category | Property | Value |

|---|---|---|

Physical | Density | 7.85 g/cm³ |

Melting Point | 1,460°C | |

Thermal Conductivity | 42.7 W/m·K | |

Coefficient of Thermal Expansion (CTE) | 12.1 µm/m·°C | |

Chemical | Carbon (C) | 0.17-0.22% |

Manganese (Mn) | 1.10-1.40% | |

Chromium (Cr) | 1.00-1.30% | |

Silicon (Si) | ≤0.40% | |

Iron (Fe) | Balance | |

Mechanical | Tensile Strength (core) | 980 MPa |

Yield Strength (core) | 685 MPa | |

Elongation | ≥15% | |

Surface Hardness (after case-hardening) | 60-62 HRC |

Suitable 3D Printing Processes for 20MnCr5

Process | Typical Density Achieved | Surface Roughness (Ra) | Dimensional Accuracy | Application Highlights |

|---|---|---|---|---|

≥99% | 8-12 µm | ±0.05 mm | Ideal for intricate geometries requiring precise tolerances, essential for gear components and precision assemblies | |

≥99.5% | 6-10 µm | ±0.05 mm | Excellent for highly detailed automotive parts, tool inserts, and prototypes demanding high surface integrity |

Selection Criteria for 20MnCr5 3D Printing Processes

Component Complexity: SLM and DMLS deliver high geometric precision (±0.05 mm), suitable for complex, small-scale automotive gears and precision mechanical components.

Mechanical Strength and Hardness: Case-hardening capability, achieving 60-62 HRC surface hardness, makes 20MnCr5 ideal for components subjected to extreme wear and dynamic loading.

Build Size Considerations: SLM efficiently handles intricate small to medium-sized components, whereas DMLS is flexible for detailed parts with precise dimensional requirements.

Post-Processing Needs: Essential heat treatments, including carburizing and case-hardening, significantly enhance surface hardness, wear resistance, and overall durability.

Essential Post-Processing Methods for 20MnCr5 3D Printed Parts

Carburizing Heat Treatment: Performed at temperatures around 900-950°C, it achieves a hardened surface of 60-62 HRC and improves wear resistance drastically.

CNC Machining: Ensures precision machining with tolerances within ±0.02 mm, vital for gear teeth profiles, bearing surfaces, and high-precision interfaces.

Nitriding: Surface treatment at 500-550°C, forming nitrides that significantly increase surface hardness, reaching 65-70 HRC, and corrosion resistance.

Shot Peening: High-velocity abrasive treatment improves fatigue life by approximately 25%, enhancing mechanical durability for heavily loaded parts.

Challenges and Solutions in 20MnCr5 3D Printing

Residual Stresses: Controlled preheating (~200°C) and stress-relieving heat treatments effectively reduce residual stresses, minimizing deformation and enhancing stability.

Case-Hardening Uniformity: Precision-controlled carburizing environments achieve consistent surface hardening depths (0.6-1.0 mm), ensuring uniform properties across complex geometries.

Surface Finish Quality: Post-processing machining and controlled parameter optimization (laser power: 180-200W, scanning speeds: 800-1000 mm/s) reduce surface roughness below 8 µm Ra.

Applications and Industry Case Studies

20MnCr5 is extensively applied in:

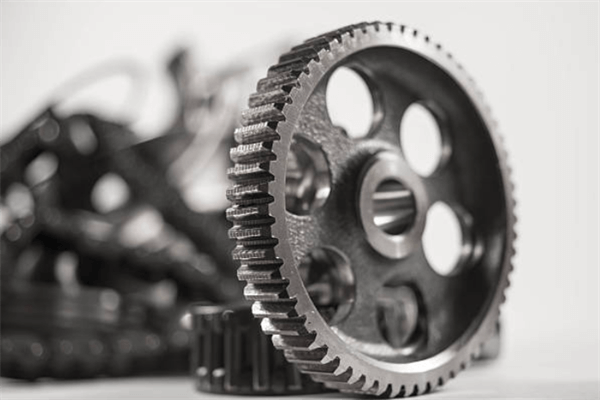

Automotive: Transmission gears, drive pinions, crankshafts.

Machinery and Tooling: High-precision machine components, tool holders.

Industrial Equipment: Heavy-duty sprockets, gearboxes, mechanical assemblies.

Aerospace: Structural brackets, gear drives, critical load-bearing parts.

Case Study: Automotive transmission gears produced via DMLS followed by carburizing treatment and CNC finishing demonstrated enhanced wear resistance and dimensional precision, significantly extending operational life.

Frequently Asked Questions (FAQs)

What are the benefits of using 20MnCr5 steel in 3D printed automotive components?

Which 3D printing technologies achieve the best dimensional accuracy for 20MnCr5 steel?

How do heat treatments influence surface hardness and wear resistance in 20MnCr5 printed parts?

What size limitations exist for components printed in 20MnCr5 steel?

How does 20MnCr5 compare with other case-hardening steels for additive manufacturing?