What is the role of carbon steel alloys in additive manufacturing for energy sector components?

What Is the Role of Carbon Steel Alloys in Additive Manufacturing for Energy Sector Components?

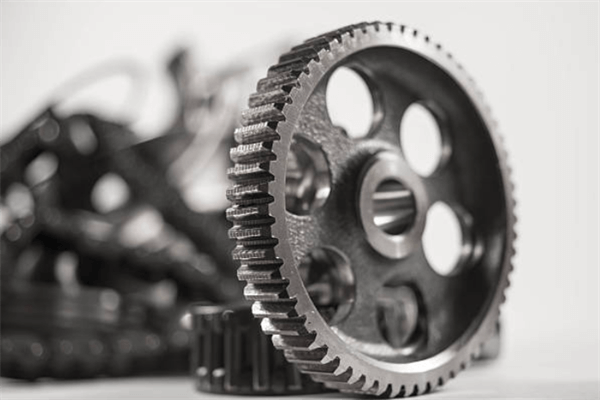

Structural Strength for Load-Bearing Applications

Carbon steel alloys like AISI 4140 and AISI 4130 play a critical role in additive manufacturing for energy sector components due to their high tensile strength, fatigue resistance, and toughness. These properties are essential for parts subjected to mechanical loading and vibration in turbines, valve bodies, compressor housings, and power transmission assemblies.

Pressure and Thermal Resistance in Harsh Environments

Energy systems such as oil and gas drilling, geothermal operations, and power generation demand materials that perform reliably under high-pressure, high-temperature conditions. Additively manufactured carbon steels can be heat treated after printing to enhance surface hardness and yield strength, ensuring long-term performance in pipeline components, flanges, and pressure seals.

Repair and Redesign of Critical Components

Using technologies like Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), carbon steel parts can be rapidly reproduced or redesigned with integrated channels, reduced weight, or optimized stiffness. This supports maintenance and lifecycle extension strategies for turbines, pumps, and pressure vessels in the energy sector.

Cost-Effective Manufacturing for Large and Customized Parts

Carbon steel’s affordability and material availability make it an economical choice for large-format or customized energy components. When combined with Binder Jetting, additive manufacturing enables high-throughput production of carbon steel parts for energy infrastructure without the cost of traditional tooling.

Customer-Oriented Solutions and Services

We support carbon steel additive manufacturing for energy sector needs with:

3D Printing Technologies:

Explore Carbon Steel 3D Printing solutions using DMLS, EBM, and Binder Jetting for structural and pressure-handling components.

Material Selection:

Choose from high-strength carbon steels like AISI 4140, Tool Steel D2, and 20MnCr5 tailored for dynamic and thermal demands.

Energy Industry Applications:

Discover our energy and power solutions, with support for heat treatment, CNC machining, and surface treatment for energy-grade certification and performance.