Which 3D printing technology is best for carbon steel parts in automotive applications?

Which 3D Printing Technology Is Best for Carbon Steel Parts in Automotive Applications?

Optimal Technology: Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is the most suitable 3D printing technology for manufacturing carbon steel parts in automotive applications. DMLS uses a high-power laser to fully fuse metal powders layer by layer, producing high-density parts with mechanical properties equivalent to wrought materials. It is ideal for fabricating carbon steel components that require strength, toughness, and wear resistance under dynamic and load-bearing conditions.

Suitable Carbon Steel Grades for Automotive Use

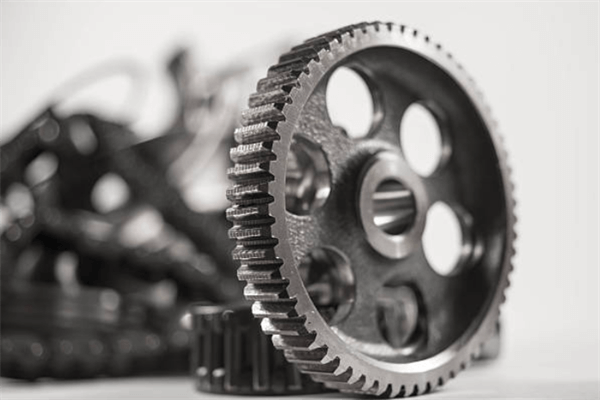

AISI 4140

Chromium-molybdenum alloy steel with high fatigue strength. Used for gears, shafts, and suspension components

AISI 4130

Excellent strength-to-weight ratio and weldability. Common in roll cages, brackets, and linkages

Tool Steel D2

High wear resistance and dimensional stability. Ideal for dies, inserts, and cutting tools

20MnCr5

Case-hardened alloy steel is used in transmission components. Excellent core toughness and surface hardness after heat treatment

Advantages of DMLS for Automotive Carbon Steel Parts

Near-net-shape production reduces machining and material waste

High resolution for integrating functional features (e.g., internal oil channels)

Fatigue and impact resistance suitable for drivetrain and structural parts

Compatible with heat treatment to enhance hardness and tensile strength

Supports the consolidation of multi-part assemblies into single, optimized structures

Customer-Oriented Solutions and Services

To meet your carbon steel part requirements in the automotive sector, we offer:

3D Printing Technologies:

Utilize our Carbon Steel 3D Printing solutions based on DMLS for high-performance, complex automotive components.

Automotive-Grade Materials:

Choose from AISI 4140, AISI 4130, Tool Steel D2, and 20MnCr5 for different structural and wear-resistant applications.

Automotive Manufacturing Support:

Explore our full automotive solutions, including CNC machining, surface treatment, and heat treatment to deliver end-use-ready parts.