Fatigue Testing: Verified Service Life for Critical AM Parts

Introduction: Beyond Static Strength – How Fatigue Testing Safeguards the Lifecycle of Critical AM Components

As additive manufacturing technology continues to mature, our challenge has shifted from “Can we make it?” to “Can it perform reliably in service?”. As a fatigue testing engineer at Neway, I have witnessed many seemingly perfect parts fail prematurely under cyclic loading. Static strength testing only tells us how a material behaves under a single load event, while in reality, most critical components—from aircraft engine blades to medical implants—operate under repeated loads. Fatigue testing is the crucial bridge between laboratory data and real-world service performance. It provides essential assurance for the reliability of AM parts operating in demanding environments.

Fundamentals of Fatigue Testing: Understanding High-Cycle and Low-Cycle Fatigue

High-Cycle Fatigue: Enduring Massive Cycles at Lower Stress Levels

High-cycle fatigue occurs when components are subjected to a large number of cycles at relatively low stress levels, typically resulting in failure after more than 10^4 cycles. This phenomenon is particularly common in high-speed rotating components, such as turbine disks and blades in the aerospace sector. In such applications, even when the applied stress is far below the material’s yield strength, fatigue failure may still occur after millions of cycles. Our focus is on determining the fatigue limit—the maximum stress amplitude at which the material can theoretically endure an infinite number of cycles without failure.

Low-Cycle Fatigue: Enduring Fewer Cycles at High Strain

In contrast, low-cycle fatigue occurs when components experience relatively few cycles at high strain amplitudes, typically resulting in failure before 10^4 cycles. This condition is typical for parts exposed to cyclic thermo-mechanical loads, such as engine blocks or certain pressure vessels. In the low-cycle regime, plastic strain dominates the damage process, so we conduct strain-controlled rather than stress-controlled tests to more accurately capture material behavior under cyclic plastic deformation.

Constructing the S-N Curve: The “Map” of Fatigue Life

The S-N curve (stress–life curve) is the fundamental tool for evaluating fatigue performance. By testing multiple specimens at different stress levels and recording the number of cycles to failure, we construct this critical curve. At Neway, we apply statistical methods to process the results, ensuring that the derived S-N curves are robust and reliable. The curve illustrates how fatigue strength varies with life and provides essential input data for fatigue-resistant design.

How Neway Conducts Fatigue Testing and Life Verification Tailored to AM

Load Spectra Designed from Real Service Conditions

We recognize that fatigue testing divorced from real service conditions is meaningless. Therefore, we work closely with our customers to develop accurate load spectra based on actual operating conditions—including load type, amplitude, frequency, and environment. For aerospace components, we simulate realistic flight profiles; for medical implants, we reproduce gait-related loading in a physiological environment. This application-driven approach ensures that test results are directly relevant and trustworthy.

Sampling Orientation Considering AM Anisotropy

The anisotropic nature of AM components is a critical factor that cannot be ignored. In powder bed fusion, the layerwise build process often leads to directional dependencies in mechanical properties. Our sampling strategy strictly follows design and qualification requirements, extracting specimens both parallel and perpendicular to the build direction. This systematic approach provides a comprehensive understanding of directional fatigue performance, supporting optimized build orientation strategies.

Quantifying the Influence of Surface Condition and Post-Processing

Surface condition has a decisive impact on fatigue life. We systematically evaluate the effect of various surface treatment methods, including shot peening/blasting, polishing, and hot isostatic pressing (HIP), on fatigue performance. By comparing fatigue life before and after each treatment, we provide data-backed recommendations for the most effective post-processing route.

Applications of Fatigue Testing in Critical Industry AM Component Development

Aerospace Engine Blades and Structural Components

In aerospace, we provide comprehensive high-cycle fatigue testing for superalloy and titanium alloy blades and structural components. By simulating actual engine thermal and mechanical loading conditions, we can accurately predict in-service fatigue life under combined high-speed rotation and thermal cycling. These results directly support compliance with FAA, EASA, and other aviation regulatory requirements.

Durability Validation for Medical Implants

For medical implants such as hip and knee joints, we use specialized test setups to simulate physiological conditions. Implants made from biocompatible materials, such as Ti-6Al-4V ELI, are subjected to tens of millions of loading cycles in simulated body fluids to verify that they can safely function for decades in vivo. These evaluations address not only fatigue strength but also corrosion fatigue behavior under physiological environments.

Testing Automotive Chassis and Powertrain Components

In the automotive sector, we conduct fatigue testing for 3D-printed lightweight suspension and powertrain components. By reproducing real-world road load spectra, we assess fatigue resistance under complex, multi-axial service conditions. These tests help customers achieve maximum lightweighting while maintaining safety, supporting the broader advancement of automotive technologies toward higher efficiency and lower emissions.

The Core Value of “Verified Service Life” for Design and Certification

The greatest value of fatigue testing lies in elevating design from empirical estimates to data-driven precision. Systematic fatigue data enable us to define safety factors based on real behavior, rather than overly conservative assumptions—crucial for weight-sensitive designs. At the same time, fatigue validation data is often mandatory for certification by authorities such as the FAA, EASA, and FDA for critical components, enabling regulatory approval and market entry. Furthermore, fatigue life predictions based on test data support predictive maintenance strategies, helping end users reduce operational risk and lifecycle costs.

Synergy Between Fatigue Testing and Other Performance Evaluations

Correlation with Tensile Test Properties

We establish empirical correlations between tensile test results and fatigue performance. While such correlations cannot replace dedicated fatigue testing, they provide useful early-stage estimates. Generally, materials with higher yield and tensile strengths tend to exhibit higher fatigue strength, helping guide design decisions when full fatigue datasets are not yet available.

Integration with Fracture Mechanics Analysis

For AM parts that inevitably contain small defects, we apply fracture mechanics-based approaches to predict fatigue life. By determining crack growth rate parameters, we can estimate the number of cycles required for a defect to grow from its initial size (as detected by inspection) to a critical size under a given loading condition. This methodology is particularly valuable when assessing the impact of defects identified by X-ray or CT inspections.

Closed-Loop Validation with Nondestructive Testing

We integrate fatigue testing with advanced NDT methods, periodically performing X-ray or CT scans during fatigue tests to monitor defect evolution. This closed-loop approach deepens our understanding of how internal flaws behave under cyclic loading and supports the development of rational, risk-based acceptance criteria.

Case Study: How Fatigue Testing Optimized the Heat Treatment Process of Inconel 718 Turbine Disks

In an aerospace engine project, we faced an interesting technical challenge. Two different heat treatment processes (A and B) applied to Inconel 718 turbine disks yielded nearly identical tensile properties, with differences in yield and tensile strength of less than 2%.

To reveal the true impact of these processes, we conducted systematic high-cycle fatigue tests. The results were striking: process B delivered approximately 15% higher fatigue strength than process A, meaning significantly longer life at the same stress level.

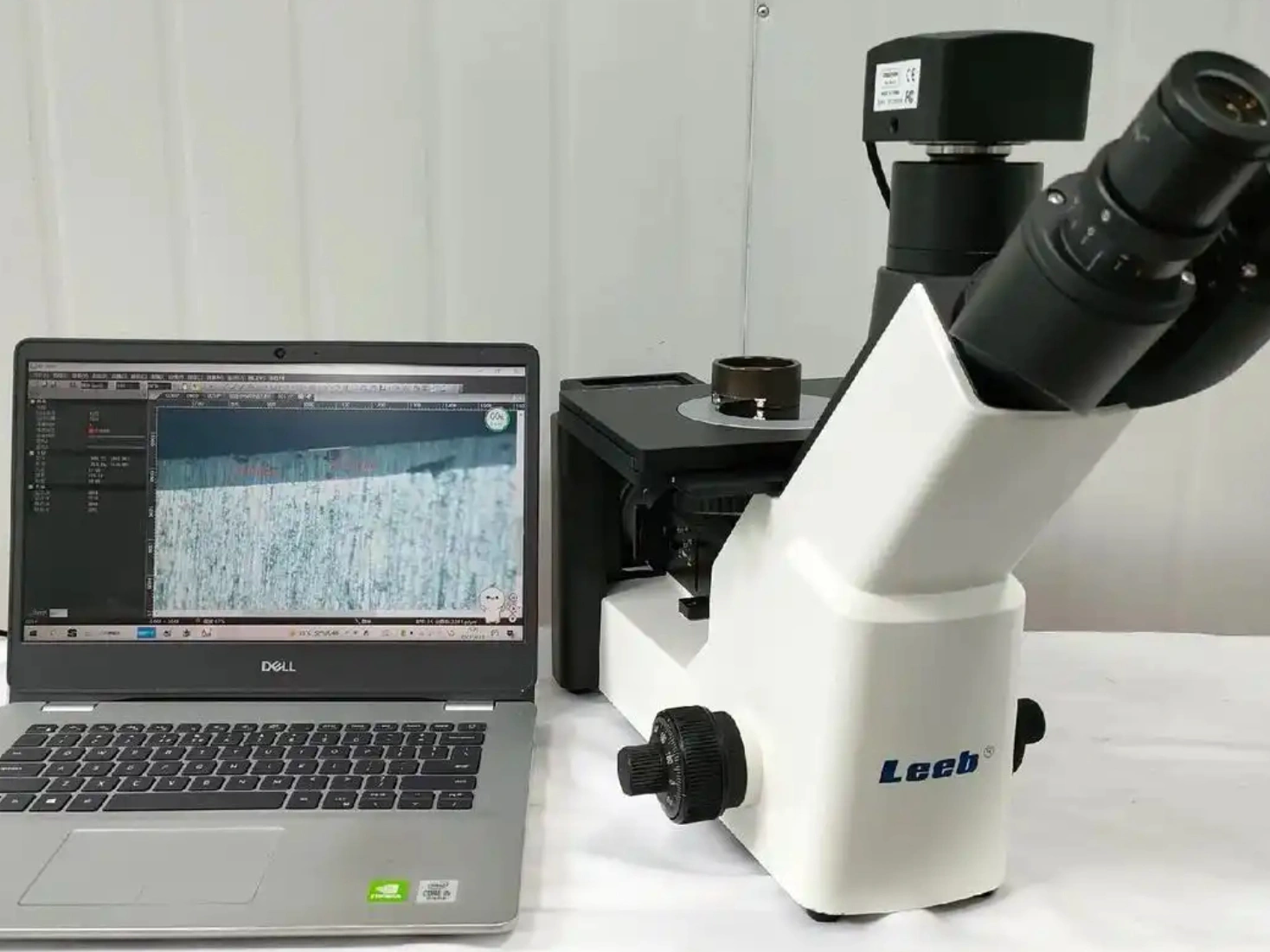

Further metallographic analysis uncovered the underlying mechanism: process B produced finer grains and a more uniform distribution of γ′ strengthening phases. While this microstructural refinement had a limited effect on static strength, it markedly improved fatigue resistance.

Based on these findings, the customer selected process B as the standard for production. This decision not only enhanced the in-service reliability of the turbine disks but also reduced maintenance costs by enabling longer inspection intervals. The case clearly demonstrates the irreplaceable role of fatigue testing in process optimization.

Conclusion: Quiet Confidence for AM Components in a Dynamic World

In today’s rapidly evolving additive manufacturing landscape, fatigue testing has become a crucial enabler for transforming innovative designs into reliable products. At Neway, through systematic methodologies and rigorous data analysis, we help our customers validate the service life of every critical component. We believe that only products verified by sound science can deliver silent, dependable performance under dynamic loading. We sincerely invite all partners who are deploying AM in critical applications to work with us in validating the future of your designs and jointly driving manufacturing toward greater reliability and efficiency.

Frequently Asked Questions

How many specimens and what duration are typically required to establish a complete S-N curve?

Can you conduct fatigue testing at elevated temperatures or in corrosive environments?

How do you prepare standard-compliant fatigue specimens from complex-shaped AM components?

How can fatigue test results be used to determine the safe service life of my parts?

How does the fatigue performance of AM parts compare with that of conventionally forged components?