How to Reduce 3D Printing Costs: 7 Practical Tips

How to Reduce 3D Printing Costs: 7 Practical Tips

Reducing 3D printing costs is essential for manufacturers aiming to transition from prototyping to scalable production. By optimizing every stage—from design to post-processing—engineers can significantly improve part economics without compromising performance or quality. The following strategies are based on Neway’s experience delivering cost-efficient solutions across high-demand industries like medical, energy, and robotics.

1. Design for Additive Manufacturing (DfAM)

A critical cost driver is how well the design leverages additive processes. Overly complex geometries, unnecessary internal voids, and sharp overhangs can increase print time and support material consumption. Applying DfAM principles such as topology optimization and lattice structures reduces mass while maintaining strength.

For example, switching from solid infill to optimized gyroid or hexagonal lattice structures in plastic 3D printing reduces raw material volume by 20–40% without affecting mechanical function. Similarly, reducing part height by reorienting geometry can cut Z-axis build time in SLA or DLP processes.

2. Choose the Right Material for the Application

Material cost can account for up to 50% of a part’s total 3D printing cost. Using high-performance materials where not needed can be wasteful. For non-load-bearing components, switching from titanium alloys to carbon steel or plastics like PA or PETG significantly lowers expenses.

For instance, polylactic acid (PLA) is ideal for display models and test fits due to its low price and printability, while nylon is preferable for functional prototypes with mechanical loads. In metal AM, aluminum AlSi10Mg offers a good strength-to-weight ratio at a lower cost than superalloys.

3. Optimize Support Structures

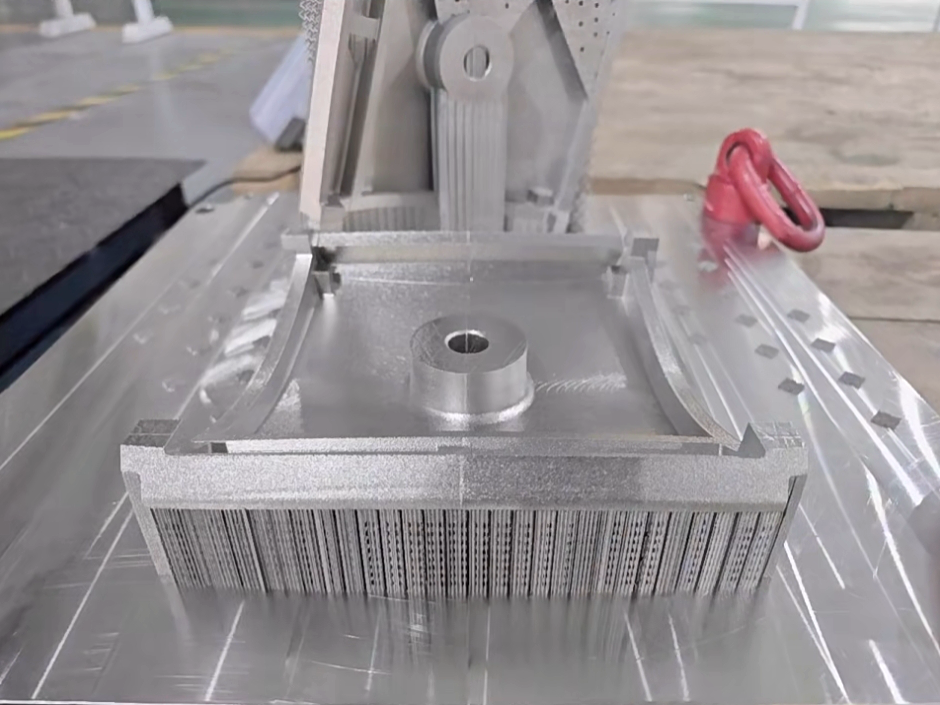

Support structures increase material usage and extend post-processing labor. Selecting the right orientation during build setup minimizes support volume. For example, minimizing overhangs exceeding 45° allows parts to print self-supported in FDM or SLS.

In metal printing technologies like DMLS, using tree-like or lattice supports reduces both powder consumption and cutting/removal effort. Advanced slicing software now allows custom support density zones and breakaway points, further lowering post-processing hours and consumable costs.

4. Consolidate Assemblies into Fewer Parts

Traditional assemblies often consist of multiple components requiring separate manufacturing, fastening, and inspection. Additive manufacturing excels at combining these into a single build. Part consolidation reduces per-unit cost by cutting handling time, inventory, and the need for fasteners.

A stainless steel 3D printed turbine nozzle previously built from five machined parts was consolidated into one, slashing production time by 60% and cost by 35%. The approach also enhances structural integrity and reduces leak paths in fluid systems.

5. Select the Most Cost-Efficient Printing Technology

Choosing the wrong 3D printing process can significantly inflate costs. Each technology has different throughput, resolution, and post-processing needs. For example, Binder Jetting enables batch production of metal or ceramic parts at a lower cost-per-part compared to DMLS, making it ideal for low-complexity components.

For large-volume plastic parts, Multi Jet Fusion (MJF) offers better speed and consistency than FDM. Resin-based technologies like SLA and CLIP deliver high-resolution finishes but at a premium, so they're better suited to dental, jewelry, or display models rather than bulk parts.

Matching part volume, tolerance, and surface requirements with the right process ensures optimal use of machine time and material, ultimately reducing cost.

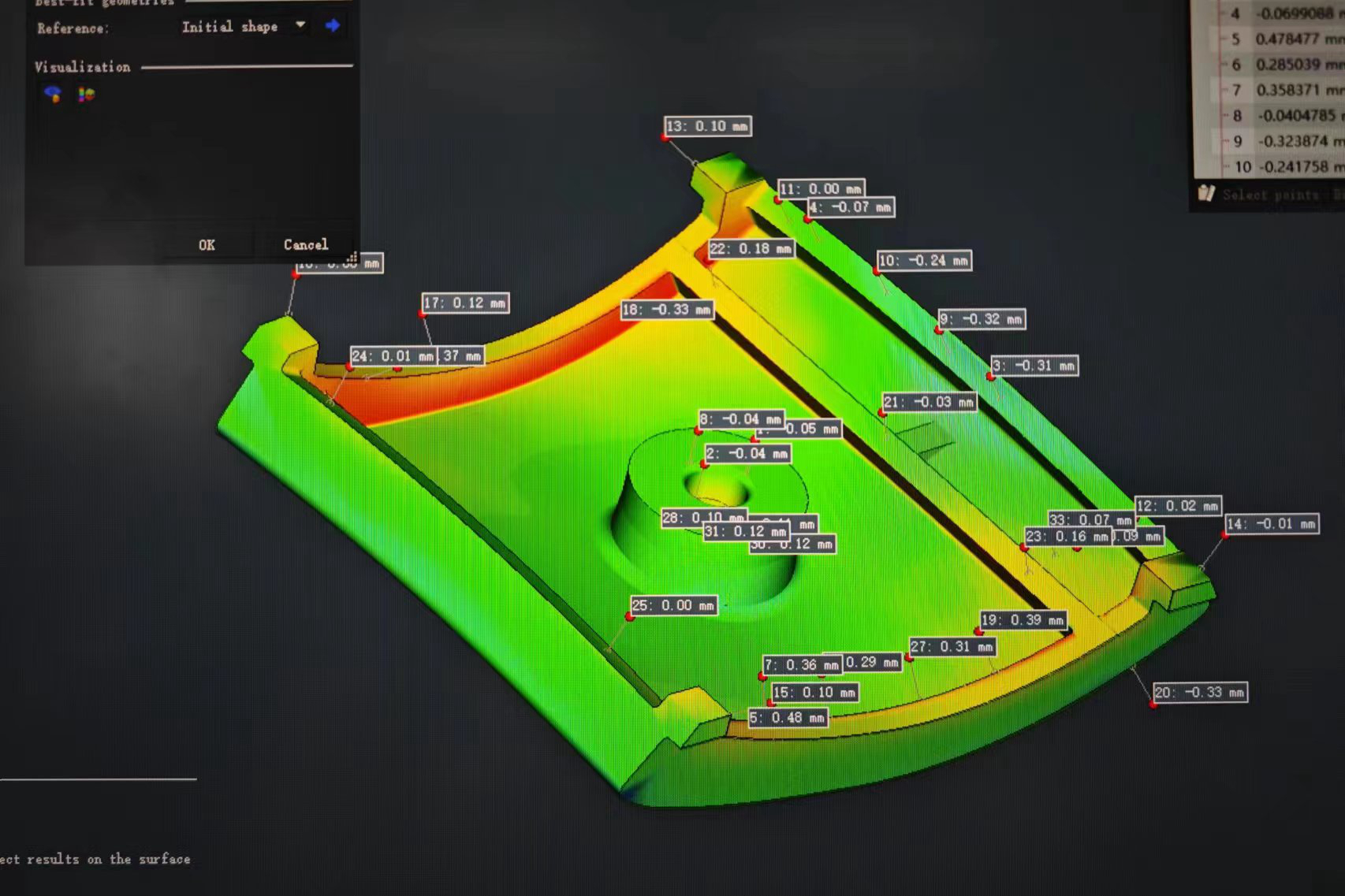

6. Optimize Post-Processing Strategy

Post-processing steps like support removal, heat treatment, surface finishing, and machining often double the cost of a printed part. Streamlining these processes reduces labor and lead time. For instance, using powder coating instead of manual polishing for surface enhancement provides a consistent finish at lower operational expense.

Minimizing the need for secondary machining through tighter process control or printing to near-net-shape is also beneficial. In metal printing, applying Hot Isostatic Pressing (HIP) eliminates internal porosity and improves fatigue strength in one step, reducing the need for costly CNC finishing or structural testing.

For precision applications, combining additive with EDM machining allows for tight-tolerance surfaces only where required, which avoids full-part secondary processing.

7. Batch Production and Nesting Strategies

Cost per part decreases significantly when print beds are fully utilized. In powder-based systems like SLM and MJF, parts can be stacked in vertical z-heights or nested in horizontal X-Y planes to fill unused build volume. Nesting multiple components into a single print job maximizes throughput and amortizes machine time across more parts.

For example, nesting 100 connectors in a single carbon steel batch reduced the cost per unit by 42% compared to individual prints. Automated nesting algorithms in advanced slicers make this process efficient even for mixed-part production runs.

Production-scale 3D printing services, such as Neway’s manufacturing and tooling offering, integrate these optimization algorithms to deliver volume pricing advantages to clients.

Cost Comparison Table: Practical Savings from Each Tip

Tip | Cost Impact | Savings Potential | Application Example |

|---|---|---|---|

DfAM | Reduces material and time | 10–30% | Gyroid infill, lattice |

Material Selection | Lower raw material cost | 15–50% | PLA vs PA6 |

Support Optimization | Minimizes post-processing | 10–25% | Breakaway supports |

Part Consolidation | Fewer assemblies, less labor | 30–60% | Integrated nozzles |

Technology Selection | Process-matched production | 20–50% | Binder Jet vs DMLS |

Post-Processing | Reduced secondary steps | 15–40% | HIP, polishing |

Batch Production | Lower per-unit cost | 25–60% | SLS nesting |

Implementing a Cost Reduction Strategy

To realize the full benefits of these cost-saving measures, companies must adopt a systematic approach to design, material selection, and production planning. This begins with an engineering-driven review of part geometry and intended application. Leveraging rapid prototyping capabilities early helps validate performance before scaling up, reducing rework and material waste in production runs.

Collaboration with a qualified 3D printing service provider enables access to advanced design optimization, material substitution, and integrated post-processing such as TBC or anodizing. These services not only streamline workflows but also deliver part cost reductions through vertical process integration.

An effective strategy also considers end-use requirements. For example, a resin-based prototype may not require post-processing if dimensional accuracy and surface finish are already acceptable. Conversely, high-performance parts used in aerospace applications may benefit from selective heat treatments to meet mechanical specifications without overprocessing.

Real-World Application: Cross-Industry Cost Reductions

A notable case involved a client in the energy sector transitioning from machined aluminum housings to 3D printed copper alloy components. By redesigning the part for Binder Jetting and eliminating internal machining, the unit cost dropped by 38% while performance was maintained through post-print sintering and HIP.

In another example, a medical equipment firm used biocompatible resin for custom surgical jigs. By consolidating the fixtures into single-build batches, they cut costs by 45% and lead time by 50%, critical in time-sensitive surgical planning.

Even in fashion and jewelry, where detail and surface quality are key, optimized resin usage and surface treatments like polishing or lacquering reduced the total finishing effort. Designs were modified to minimize unsupported structures, allowing more efficient SLA use.

Summary and Key Takeaways

Cost reduction in 3D printing is not a single decision but a cumulative effect of strategic choices made across the entire development-to-production pipeline. The seven tips detailed above cover both digital design and physical execution:

Apply DfAM principles to minimize volume and support.

Choose materials aligned with mechanical needs and economics.

Reduce or eliminate unnecessary supports.

Consolidate parts to reduce handling and labor.

Match printing technology to production volume and precision.

Streamline post-processing with process-specific finishing.

Use nesting and batching to drive down per-unit cost.

Partnering with a vertically integrated provider like Neway 3D Printing ensures these decisions are made with full process visibility, delivering both engineering-grade quality and long-term cost savings.

For product developers, design engineers, and sourcing managers, these insights are actionable today and scalable across future product lifecycles. As additive manufacturing matures, cost-efficient innovation will remain the cornerstone of competitive advantage.

Frequently Asked Questions

What design changes have the biggest impact on reducing 3D printing costs?

How can material selection influence both price and part performance?

What are the most cost-efficient 3D printing technologies for metal parts?

How do post-processing methods contribute to the total cost of a part?

What industries benefit most from consolidated part design in additive manufacturing?