Inconel 718 3D Printing: Get Custom-Printed Metal Parts In days

Introduction

Inconel 718 is a nickel-based superalloy known for its outstanding high-temperature strength, corrosion resistance, and fatigue performance. It is widely used in aerospace, energy, and high-performance tooling, where conventional manufacturing methods often face limitations in lead time and design flexibility. With the advent of Inconel 718 3D printing, manufacturers can now produce custom metal components in as little as 3 to 7 days, dramatically accelerating product development cycles.

Advanced 3D printing services combined with optimized material processing enable the fabrication of complex geometries, such as internal cooling channels and lightweight lattice structures, while maintaining excellent mechanical integrity. Supported by robust superalloy 3D printing capabilities and comprehensive post-processing, Inconel 718 parts today meet or exceed aerospace and energy sector standards, offering a rapid and reliable path to production.

Why Inconel 718 Is Ideal for 3D Printing

Exceptional Mechanical Properties

Inconel 718 offers a unique combination of high-temperature strength, corrosion resistance, and excellent fatigue performance, making it a perfect candidate for additive manufacturing. This alloy maintains tensile strengths exceeding 1,200 MPa and operates reliably at temperatures up to 700 °C. Parts produced with superalloy 3D printing exhibit excellent resistance to oxidation, creep, and fatigue, which are critical in aerospace engines and energy applications.

Excellent Printability

Inconel 718 is highly compatible with Powder Bed Fusion technologies such as Selective Laser Melting (SLM). The alloy’s good flowability and stable melting behavior result in dense, crack-free components with fine surface finishes. Layer thicknesses between 20 to 60 microns and dimensional accuracy within ±0.1 mm are achievable, enabling intricate part geometries and precision features.

Proven Industry Applications

Inconel 718 3D printing is well-established across demanding industries. In aerospace and aviation, it is used to fabricate turbine blades, combustion chambers, and structural brackets. The energy and power sector applies Inconel 718 for heat exchangers, turbine nozzles, and high-temperature valve components. In both fields, additive manufacturing reduces lead time, eliminates tooling costs, and enables innovative designs that improve performance and reliability.

How Inconel 718 3D Printing Process Works

From Design to Final Part

The additive manufacturing workflow for Inconel 718 begins with optimized CAD design. Engineers apply Design for Additive Manufacturing (DfAM) principles to leverage the material’s capabilities, enabling lightweight lattice structures, internal cooling channels, and integrated assemblies. Advanced simulation software ensures proper stress distribution and heat management during printing.

During pre-print preparation, build parameters such as laser power, scan speed, and hatch spacing are meticulously tuned to maximize density and surface quality. State-of-the-art 3D printing technologies used in custom parts manufacturing enable faster build rates while ensuring consistency across production runs.

Powder Preparation and Quality Control

High-quality Inconel 718 powder is critical to achieving aerospace-grade results. The powder typically meets ASTM B637 and AMS 5662/5663 specifications, ensuring controlled particle size distribution, flowability, and chemical composition. Each powder batch undergoes rigorous testing for oxygen, nitrogen, and hydrogen content, which directly impact part quality and mechanical properties.

Powder Bed Fusion for Inconel 718

Selective Laser Melting (SLM) is the primary technique used to process Inconel 718. The process involves spreading layers of powder 20 to 60 microns thick, which are selectively melted by a high-power laser. Build parameters are optimized to achieve relative densities greater than 99.9%, with minimal porosity and excellent mechanical strength.

SLM enables dimensional tolerances of ±0.1 mm and surface finishes down to Ra 6–12 µm before post-processing. The process is ideal for complex, thin-walled structures required in aerospace and energy applications.

Post-Processing to Meet Performance Requirements

Heat Treatment for Inconel 718

Post-processing is essential to unlocking the full potential of Inconel 718. The standard solution and aging heat treatment significantly enhance strength, ductility, and fatigue life. A typical cycle involves solution treatment at 980 °C followed by double aging at 720 °C and 620 °C, producing a uniform γ' and γ'' precipitation hardening structure. Aerospace and energy applications often require this process to meet AMS 5662/5663 standards.

Professional heat treatment services ensure precise temperature control and atmosphere management. In combination with heat treatment post-process techniques, Inconel 718 parts achieve tensile strengths of 1,200–1,400 MPa and excellent fatigue resistance.

HIP for Full Density

Hot Isostatic Pressing (HIP) further enhances the quality of Inconel 718 components. This process uses high temperature (1,200–1,250 °C) and pressure (up to 200 MPa) to eliminate residual porosity and microdefects, ensuring nearly 100% theoretical density. The result is improved fatigue life, fracture toughness, and isotropic mechanical properties.

In critical industries such as aerospace, HIP is a standard requirement for high-load components. Studies show that enhanced mechanical properties achieved via HIP can extend component service life by 50% or more in fatigue-sensitive environments.

CNC Machining for Tight Tolerances

After HIP and heat treatment, CNC machining is employed to achieve final dimensional tolerances and surface finishes. Inconel 718 is notoriously difficult to machine due to its work-hardening behavior, but specialized tooling and optimized machining strategies ensure precision results.

For aerospace and tooling applications, tolerances of ±0.01 mm are achievable, with surface finishes improved to Ra ≤0.8 µm. Machined Inconel 718 components meet strict industry certification standards, such as AS9100.

Surface Treatments for Harsh Environments

Final surface treatment steps enhance corrosion resistance and wear properties. Common techniques include chemical passivation, electropolishing, and PVD coatings. In the energy sector, turbine components often undergo TBC (Thermal Barrier Coatings) to withstand temperatures exceeding 1,000 °C.

A range of typical surface treatments for 3D-printed parts is available to tailor Inconel 718 parts for specific operating environments, ensuring long-term durability and reliability.

Industrial Applications of Inconel 718 3D Printed Parts

Aerospace Engine Components

Inconel 718 is widely used in aerospace for critical engine components such as turbine blades, nozzles, combustion chambers, and structural brackets. Its ability to maintain mechanical strength and oxidation resistance at elevated temperatures makes it ideal for high-pressure, high-temperature sections of gas turbine engines.

Superalloy parts produced via 3D printing allow for optimized geometries, such as integrated cooling channels, which improve thermal efficiency and extend component life. The lead time for complex aerospace parts is reduced by up to 60% compared to traditional casting methods.

Energy and Turbomachinery

In the energy and power sector, Inconel 718 components are used in turbine blades, high-temperature heat exchangers, fuel nozzles, and valve assemblies. The material’s superior fatigue and creep resistance under cyclic loading conditions are critical for components in steam turbines, gas turbines, and nuclear reactors.

To ensure dimensional stability and minimize material stress, EDM machining techniques are often used on Inconel 718 printed parts. This approach allows precise finishing of internal features and delicate geometries that are difficult to access through conventional machining.

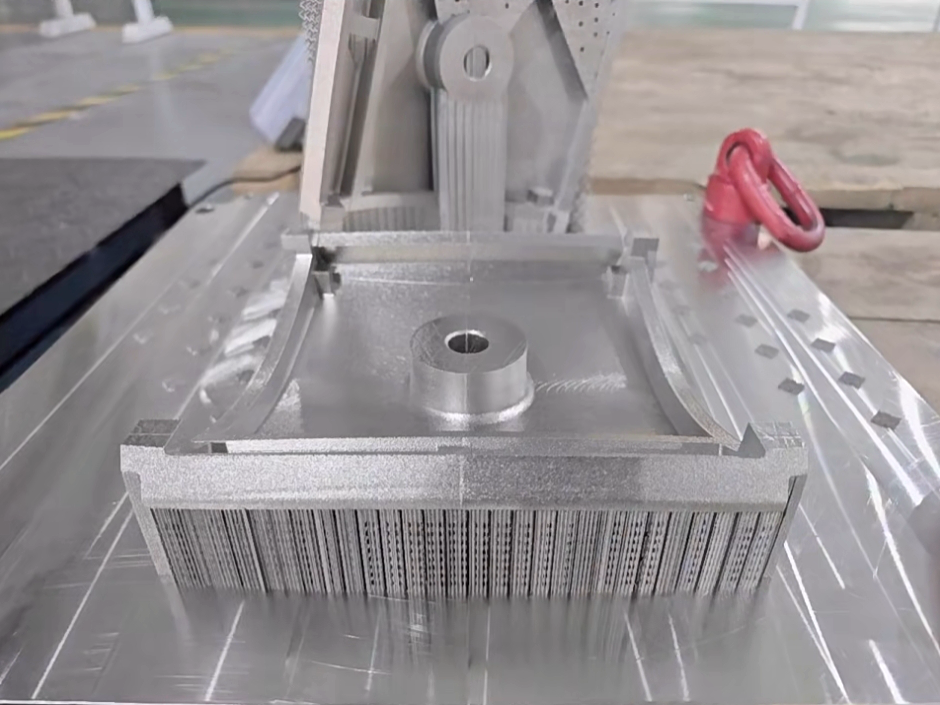

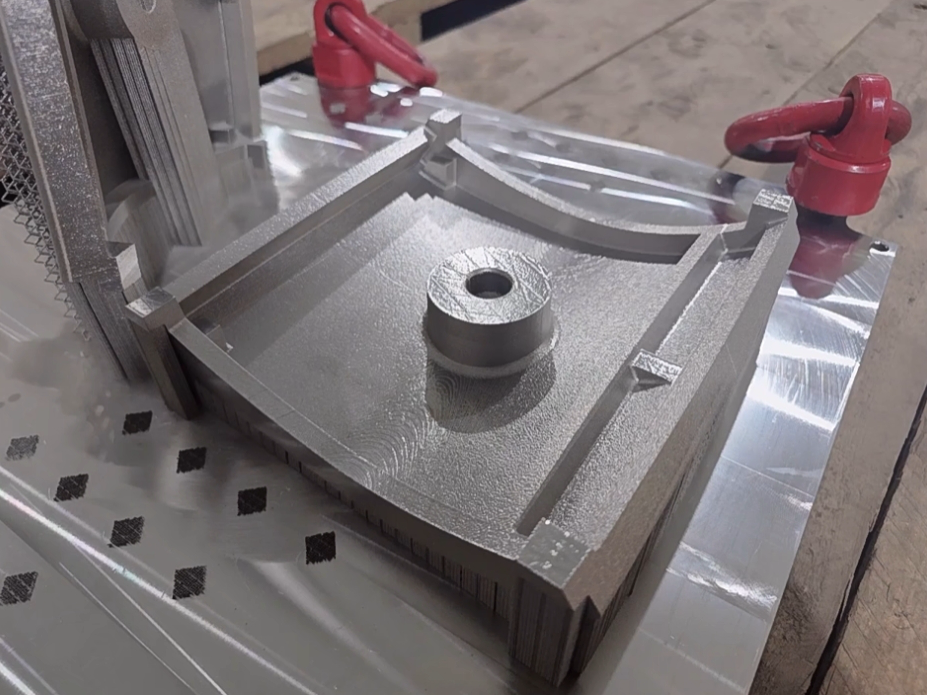

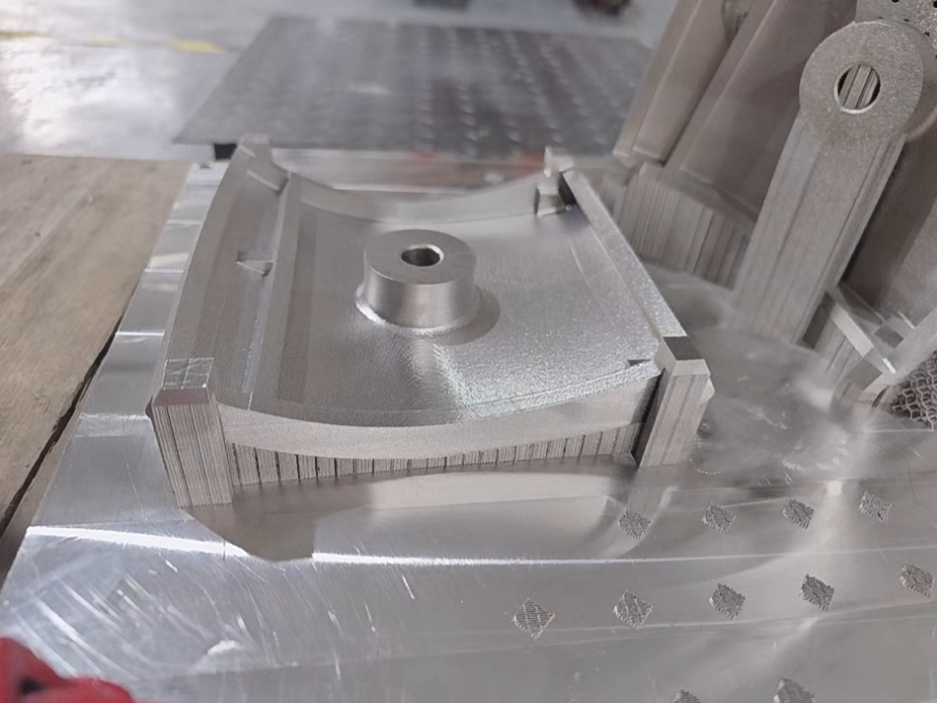

Industrial Tooling and Molds

Inconel 718’s wear resistance and thermal conductivity make it suitable for high-performance manufacturing and tooling applications. It is frequently used to produce injection mold inserts, extrusion dies, and hot work tooling that must withstand repeated thermal cycling.

3D printed tooling inserts can incorporate conformal cooling channels, reducing cycle times by up to 30% while improving product quality. The ability to rapidly produce custom mold components in days gives manufacturers a significant advantage in responding to market demands.

Automotive and Motorsports

In automotive and motorsports industries, Inconel 718 is used for lightweight, high-strength exhaust components, turbocharger housings, and structural brackets. The material’s excellent high-temperature performance is critical for parts exposed to extreme thermal environments, such as racing engines.

3D printing enables the production of thin-walled, complex exhaust manifolds that optimize gas flow and improve engine efficiency. The ability to iterate designs quickly and deliver parts in days is invaluable in the fast-paced world of motorsport development.

Why Choose Professional Inconel 718 3D Printing Services

Partnering with an experienced 3D printing service provider ensures that Inconel 718 parts meet the highest quality and performance standards. Professional suppliers offer fully certified processes (ISO 9001, AS9100) and validated material data, giving manufacturers confidence in part reliability for aerospace, energy, and industrial applications.

By leveraging advanced 3D printing materials and end-to-end capabilities — from powder selection through heat treatment, HIP, machining, and surface finishing — customers can achieve aerospace-grade mechanical properties and superior part quality. Industry leaders are also adopting lessons from custom stainless steel 3D printing to further enhance Inconel 718 production workflows.

Most importantly, professional Inconel 718 3D printing services enable rapid delivery: custom parts can be printed, processed, and shipped in as little as 3 to 7 days. This accelerates product development cycles and provides the flexibility to produce complex, high-value components on demand.