Continuous Liquid Interface Production (CLIP): 3D Printing Technology Explained

Continuous Liquid Interface Production (CLIP) is an innovative 3D printing technology that combines the precision of traditional methods with the speed and efficiency needed for high-volume production. CLIP utilizes a unique process where a part is continuously printed from a liquid resin, eliminating the need for the step-by-step layer-by-layer curing of other 3D printing methods like SLA. This technology has revolutionized how parts are created, enabling faster production times and producing high-quality, functional parts with exceptional detail.

In this guide, we will explore the CLIP technology, how it works, the materials it uses, its advantages, and its applications in industries such as automotive, medical, and consumer electronics.

How Continuous Liquid Interface Production (CLIP) Works

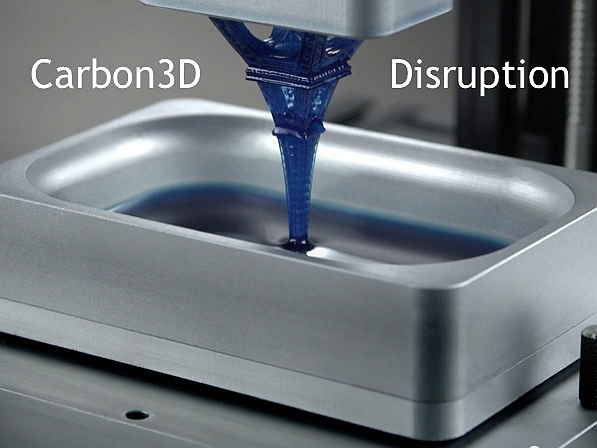

CLIP is based on a process that continuously prints parts using a unique photopolymerization technique. Unlike traditional 3D printing methods, where each layer is printed separately, CLIP uses a constant flow of resin to build a part seamlessly. The process begins with a build platform submerged in a tank of liquid resin, with a special light source positioned below the surface. As the light shines through the resin, it selectively cures it layer by layer, continuously pulling the part out of the resin pool without stopping and starting.

This continuous printing process allows CLIP to produce parts significantly faster than traditional methods, reducing print times by up to 100 times in some cases. The technique offers high resolution and fine detail, similar to that of Stereolithography (SLA), but with the added benefit of faster production.

The CLIP 3D Printing Process

1. Material Preparation

The CLIP process starts with a specially formulated photopolymer resin, which is often designed to have specific properties depending on the application. The resin is loaded into the CLIP machine, which maintains a liquid state while the light source continuously cures it. These resins can be formulated for various properties, such as flexibility, toughness, or high-temperature resistance, making CLIP suitable for various applications.

2. Continuous Curing with Light

Once the resin is loaded, the machine begins the continuous curing process. A light source beneath the resin tank projects a specific pattern onto the resin, hardening it as the part is pulled from the liquid. This process is continuous, meaning the part is always printed, with no pauses between layers. The resin’s liquid interface remains in place, and the part is gradually pulled upwards as more material is cured.

3. Fast and Efficient Printing

The beauty of CLIP lies in its speed. While traditional 3D printing methods take hours to produce a part due to the step-by-step layer curing, CLIP can complete the process much faster by continuously curing the material. The process takes minutes instead of hours to days, making it an ideal solution for mass production and quick turnaround times in industries requiring high precision.

4. Post-Processing

After printing, parts made with CLIP technology typically undergo a post-curing process to solidify the material further and enhance the properties. This post-processing often involves placing the parts in an ultraviolet (UV) light chamber to complete the curing process, ensuring the part reaches its maximum strength and durability. The part is then washed and cleaned to remove any excess resin before it is ready.

Advantages of CLIP 3D Printing

Speed: One of the most significant advantages of CLIP over other 3D printing methods is its speed. CLIP can print parts in minutes instead of hours, making it ideal for quick-turnaround prototyping and production.

High Resolution: CLIP technology provides exceptional resolution and detail, with layer thicknesses as small as 25 microns. This allows for producing intricate geometries and fine features that are difficult to achieve with other methods.

Continuous Process: The continuous printing process eliminates the need for stopping and starting between layers, reducing print time significantly and ensuring a smoother finish on the final product.

Material Variety: CLIP supports various flexible, durable, and heat-resistant resins. These materials can be tailored to specific applications in industries such as automotive and medical.

Materials Used in CLIP 3D Printing

CLIP uses specially formulated photopolymer resins that can be customized for various applications. The table below highlights some of the most commonly used materials in CLIP printing:

Material | Properties | Applications |

|---|---|---|

Strong, impact-resistant, durable | Functional prototypes, mechanical parts, automotive parts | |

Flexible, rubber-like, high elongation | Seals, gaskets, wearables | |

Heat-resistant, stiff | Automotive components, aerospace parts, heat shields | |

Burns clean for metal casting | Jewelry, dental applications, molds |

Common Applications of CLIP 3D Printing

CLIP has a variety of applications across several industries, thanks to its speed, precision, and versatility:

Prototyping: Due to its speed, CLIP is widely used for rapid prototyping in industries such as automotive, aerospace, and consumer electronics. The technology allows engineers to produce quickly and iterate designs.

End-Use Parts: CLIP is increasingly being used to produce low-volume functional parts, including durable automotive components, customized medical devices, and tooling fixtures.

Jewelry and Casting: CLIP's ability to produce high-resolution parts with a smooth surface finish makes it ideal for creating investment casting patterns in jewelry production.

Medical Devices: The ability to print high-precision parts quickly has made CLIP a popular choice for creating custom medical implants, prosthetics, surgical guides, and tools.

Why Choose CLIP 3D Printing?

CLIP 3D printing offers a unique blend of speed, accuracy, and material versatility, making it an ideal choice for industries that require fast turnaround times, high precision, and custom solutions. Whether you're in automotive, medical, or consumer goods, CLIP provides a reliable method for producing functional prototypes, low-volume production parts, and custom solutions with exceptional quality.

To learn more about CLIP 3D printing and other 3D printing technologies, visit our website.

FAQs:

What makes CLIP 3D printing faster than other 3D printing technologies like SLA?

Can CLIP 3D printing be used for mass production?

What materials are suitable for CLIP 3D printing?

How does CLIP 3D printing compare to FDM and SLA regarding resolution?

What industries benefit most from using CLIP technology?