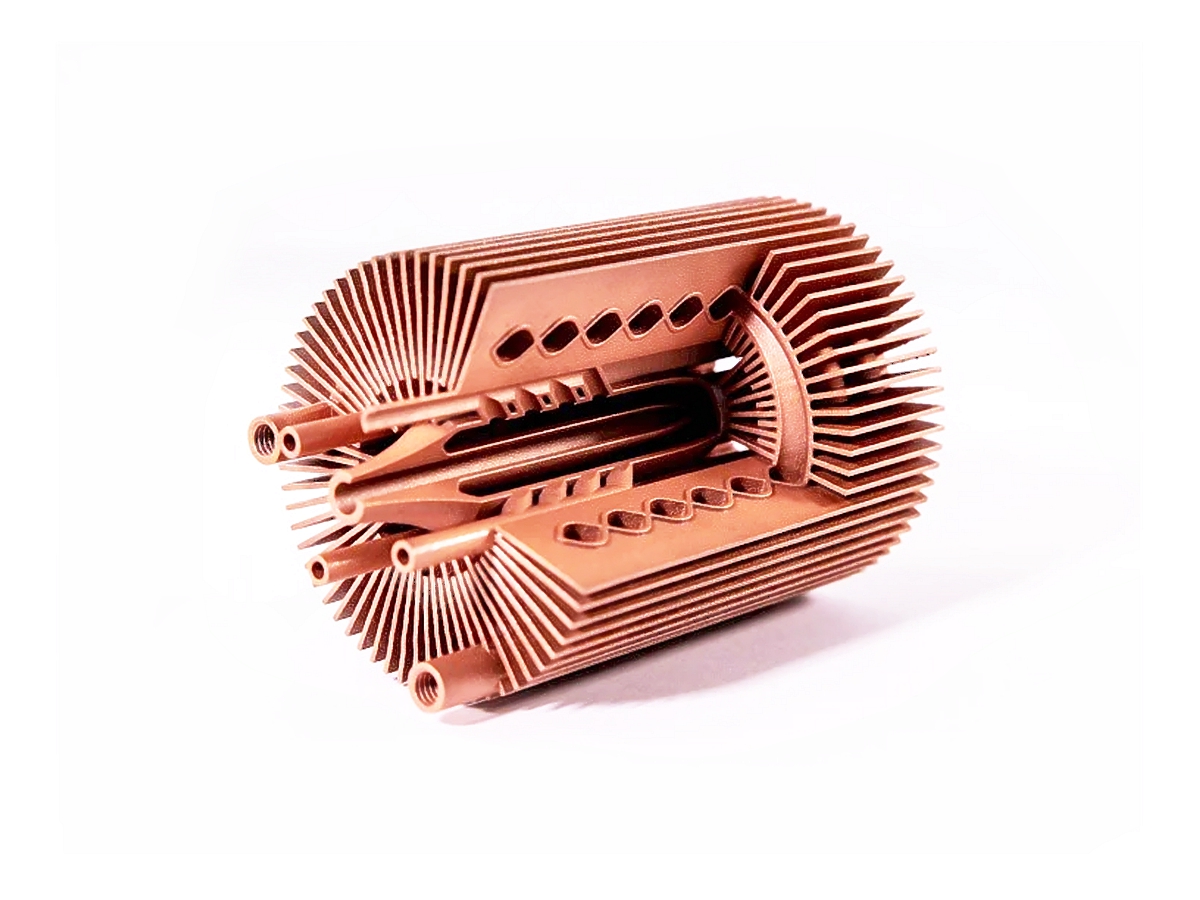

Enhancing Performance: Custom Copper 3D Printed Heat Sinks for Sports Equipment Innovation

Introduction

Copper 3D printing is driving innovation in sports equipment by enabling the production of custom-designed, high-performance heat sinks and thermal management components. Utilizing advanced metal 3D printing technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), premium copper alloys like Copper C101 and GRCop-42 offer outstanding thermal conductivity, ideal for optimizing temperature regulation in advanced athletic gear and electronic sports accessories.

Compared to traditional manufacturing, copper 3D printing for sports equipment enables complex, lightweight, and efficient heat sink designs customized to maximize performance and comfort.

Applicable Material Matrix

Material | Electrical Conductivity (% IACS) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Purity (%) | Sports Equipment Suitability |

|---|---|---|---|---|---|

≥99 | 390–400 | 220 | 99.99% | Ultra-high conductivity components | |

≥97 | 380–390 | 210 | 99.90% | General thermal applications | |

~80 | 275–300 | 350 | Alloyed | High-temperature cooling systems | |

75–80 | 300–320 | 450 | Alloyed | High-strength thermal structures | |

≥99.95 | 390–400 | 200 | 99.95% | Lightweight cooling elements | |

25–30 | 200–220 | 600 | Alloyed | Corrosion-resistant sports components |

Material Selection Guide

Copper C101: Offers unmatched thermal conductivity (~400 W/m·K) and electrical performance, ideal for ultra-efficient cooling systems in smart sports equipment like wearable sensors or powered athletic gear.

Copper C110: Provides excellent conductivity and durability, widely used in general sports device cooling, where cost efficiency is prioritized.

GRCop-42: High-strength and creep-resistant at elevated temperatures, GRCop-42 is suitable for heat sinks in performance electronics integrated into racing bikes, smart helmets, or endurance sports gear.

CuCr1Zr: Combines good thermal conductivity with enhanced mechanical strength, perfect for rugged outdoor sports equipment requiring efficient heat management and mechanical durability.

Pure Copper: Ultra-high purity is best for lightweight cooling solutions in compact wearable devices such as fitness trackers, smart sports clothing, or advanced e-bikes.

CuNi2SiCr: Suitable for marine or outdoor sports applications where corrosion resistance is essential alongside thermal performance.

Process Performance Matrix

Attribute | Copper 3D Printing Performance |

|---|---|

Dimensional Accuracy | ±0.05 mm |

Density | >99.5% Theoretical Density |

Layer Thickness | 30–60 μm |

Surface Roughness (As-Printed) | Ra 5–12 μm |

Minimum Feature Size | 0.3–0.5 mm |

Process Selection Guide

Complex Thermal Design Integration: 3D printing enables the production of intricate fin structures, micro-channel heat sinks, and custom geometries optimized for rapid heat dissipation with minimal material usage.

Lightweight Optimization: Topology optimization and lattice structures reduce weight while maintaining high thermal performance, which is critical for maintaining mobility and comfort in sports applications.

Superior Surface Finishing: Post-processing like electropolishing enhances surface smoothness and conductivity for maximum heat transfer efficiency.

Rapid Customization: Prototyping and small-batch production of device-specific cooling solutions enable quicker innovation cycles for sports technology manufacturers.

Case In-Depth Analysis: C101 3D Printed Custom Heat Sink for Smart Cycling Helmet

A premium cycling brand required a lightweight, high-efficiency heat sink for integration into a smart helmet system featuring active cooling and environmental sensors. Using our copper 3D printing service with Copper C101, we produced custom heat sinks with conductivity ≥99% IACS and ultra-fine micro-channel designs. The solution reduced helmet core temperatures by 15% during endurance trials without adding significant weight. Post-processing included CNC machining for mounting precision and surface polishing for optimal thermal transfer.

Industry Applications

Sports Equipment Innovation

Smart helmets with active cooling systems.

E-bike and electric skateboard motor cooling assemblies.

Wearable fitness sensors and body cooling modules.

Athletic Performance Wearables

Heat sinks for smartwatches and fitness trackers.

Integrated thermal management for bright clothing and gear.

Outdoor and Extreme Sports Gear

Cooling modules for endurance racing and adventure equipment.

Marine and weather-resistant electronics with custom thermal designs.

Mainstream 3D Printing Technology Types for Copper Sports Components

Selective Laser Melting (SLM): Best for producing ultra-dense, high-conductivity copper heat sinks and custom thermal structures.

Direct Metal Laser Sintering (DMLS): Ideal for highly detailed, lightweight cooling systems.

Binder Jetting: Suitable for producing moderate-conductivity copper parts at a lower cost for early-stage product development.

FAQs

Which copper alloys are best for 3D printed heat sinks in sports equipment?

How does copper 3D printing improve thermal management in athletic gear?

What post-processing methods enhance performance of 3D printed copper heat sinks?

Can copper 3D printed cooling systems be integrated into wearable sports technology?

How does 3D printing accelerate innovation in smart and endurance sports equipment?