Copper GRCop-42

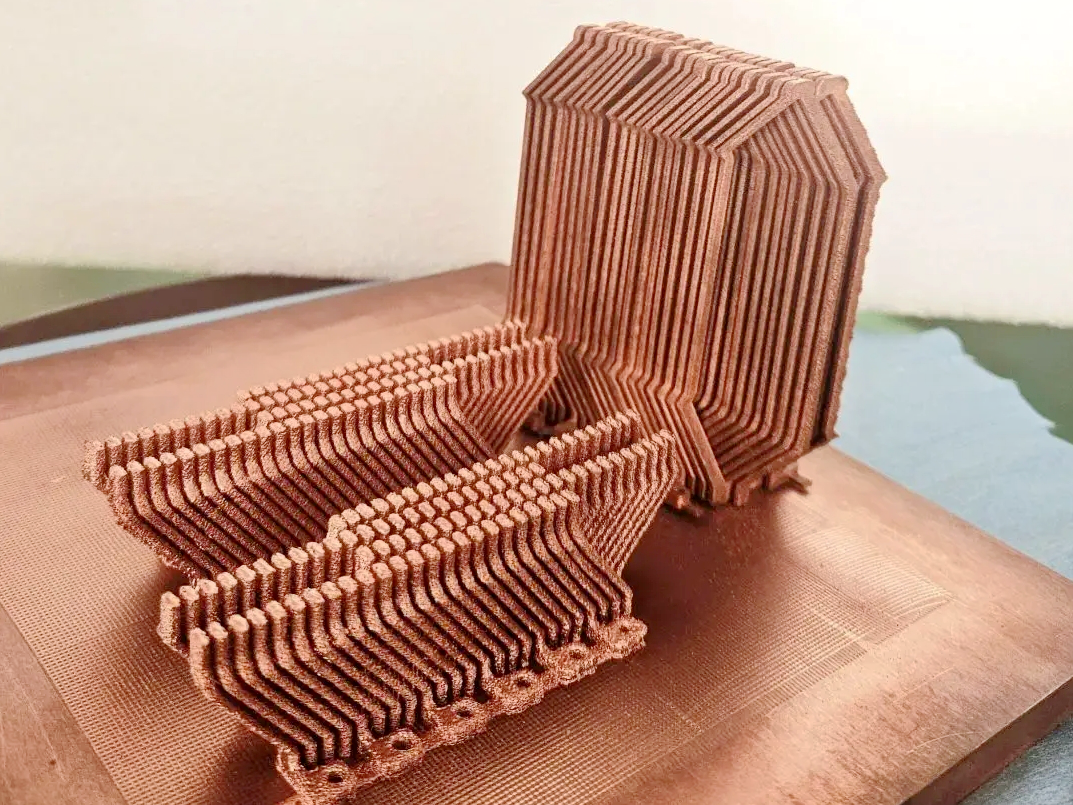

Introduction to Copper GRCop-42 for 3D Printing

GRCop-42 is a NASA-developed copper alloy containing ~4% chromium and ~2% niobium. It offers exceptional thermal conductivity (≈320 W/m·K), high strength (up to 550 MPa), and outstanding oxidation resistance at elevated temperatures, making it ideal for rocket nozzles, combustion chambers, and high-heat flux components.

Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) enable GRCop-42 to be printed with fine geometry control (±0.05 mm) while maintaining thermal-mechanical properties suited for aerospace and energy-critical systems.

International Equivalent Grades of GRCop-42

Country | Grade Number | Other Names/Titles |

|---|---|---|

USA | GRCop-42 | NASA Alloy |

— | — | CuCrNb (4–2) |

Custom | AM Copper | No commercial equivalents |

Comprehensive Properties of Copper GRCop-42

Property Category | Property | Value |

|---|---|---|

Physical | Density | 8.81 g/cm³ |

Melting Point | ~1,075°C | |

Thermal Conductivity | ~320 W/m·K | |

Electrical Conductivity | ~75–80% IACS | |

Chemical | Copper (Cu) | Balance |

Chromium (Cr) | 3.5–4.5% | |

Niobium (Nb) | 1.5–2.5% | |

Mechanical | Tensile Strength (as-built) | 450–550 MPa |

Yield Strength | 400–450 MPa | |

Elongation | ≥10% | |

Hardness (Vickers HV) | ~120 HV |

Suitable 3D Printing Processes for Copper GRCop-42

Process | Typical Density Achieved | Surface Roughness (Ra) | Dimensional Accuracy | Application Highlights |

|---|---|---|---|---|

≥99.5% | 6–10 µm | ±0.05 mm | Best for complex nozzles, heat sinks, and intricate cooling structures | |

≥99% | 10–14 µm | ±0.1 mm | Ideal for durable heat exchangers, thermal plates, and mechanical assemblies |

Selection Criteria for GRCop-42 3D Printing Processes

High-Temperature Applications: GRCop-42 maintains thermal stability and oxidation resistance above 600°C, ideal for aerospace propulsion and energy transfer systems.

Precision in Internal Channels: SLM supports thin-walled geometries and internal passages for regenerative cooling with tight tolerances and reliable wall thickness.

Mechanical Strength with Conductivity: Combines 550 MPa strength with 75% IACS conductivity, perfect for hybrid thermal-structural parts in cryogenic and hot gas environments.

Post-Processing Requirements: HIP and heat treatment are essential to remove internal porosity, enhance mechanical properties, and stabilize grain structures.

Essential Post-Processing Methods for GRCop-42 3D Printed Parts

Hot Isostatic Pressing (HIP): Performed at 1,050°C, 100 MPa; improves fatigue strength, closes internal pores, and increases long-term thermal stability.

Heat Treatment: Annealing at ~500–650°C for 1–2 hours optimizes mechanical properties while preserving conductivity and reducing microsegregation.

CNC Machining: Final shaping with ±0.02 mm precision, critical for nozzle alignment, sealing faces, and component mating surfaces.

Tumbling and Surface Polishing: Used to reduce Ra for smoother gas flow in thermal channels and reduce fatigue initiation points in pressure applications.

Challenges and Solutions in GRCop-42 3D Printing

Cracking Sensitivity: Slow scan speeds and optimized interlayer heating reduce residual stress and eliminate cold cracking during build.

Porosity Formation: High build densities (≥99.5%) are achieved using controlled laser energy input and post-HIP consolidation.

Powder Handling and Consistency: Strict atmosphere control ensures oxygen levels remain below 50 ppm to prevent property degradation and ensure print repeatability.

Applications and Industry Case Studies

GRCop-42 is widely used in:

Aerospace Propulsion: Rocket combustion chambers, nozzles, thrust chamber liners.

Thermal Management: Heat exchangers, cold plates, and high-power RF dissipators.

Energy Systems: High-efficiency energy transfer blocks, fusion device cooling arms, and cryogenic thermal paths.

Defense & Space: Laser absorbers, cooled missile components, and satellite heat flux structures.

Case Study: A 3D printed regenerative nozzle liner in GRCop-42 demonstrated stable structural performance at >600°C, with internal channels maintaining ±0.05 mm precision after HIP and annealing.

Frequently Asked Questions (FAQs)

What temperature range is GRCop-42 suitable for in 3D printed aerospace parts?

How does GRCop-42 compare to pure copper or CuCr1Zr for thermal conductivity?

What post-processing techniques are necessary for optimal GRCop-42 properties?

Is GRCop-42 suitable for vacuum or cryogenic thermal management systems?

What design rules apply for internal channels in 3D printed GRCop-42 heat exchangers?