What copper materials are commonly used in Selective Laser Melting (SLM)?

What Copper Materials Are Commonly Used in Selective Laser Melting (SLM)?

Overview

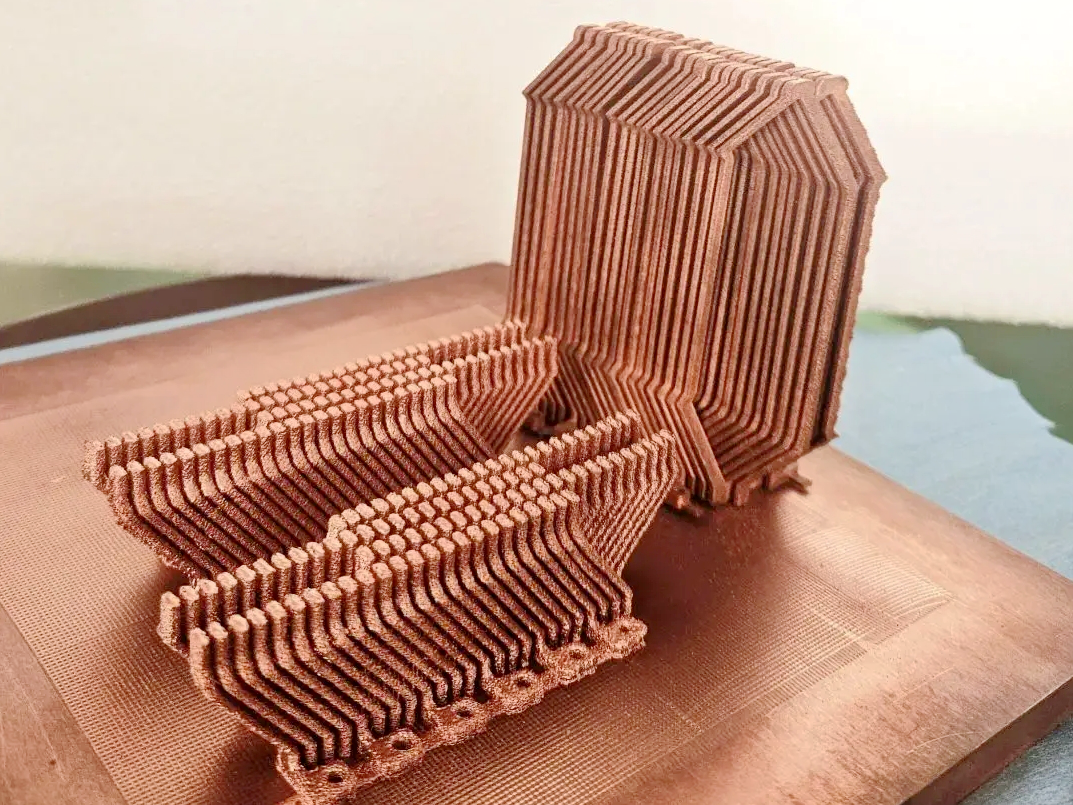

Selective Laser Melting (SLM) enables the additive manufacturing of copper components with high electrical and thermal conductivity, making it suitable for complex parts in electronics, thermal management, and RF applications. Due to copper’s high reflectivity and thermal conductivity, processing requires optimized parameters and, in many cases, green or high-power infrared lasers to achieve full density.

Common Copper Materials for SLM

Copper C101 (Oxygen-Free High Conductivity)

Electrical conductivity: >100% IACS

Thermal conductivity: ~390–400 W/m·K

Excellent for inductors, heat exchangers, antennas, and connectors in electronics

Oxygen-free formulation ensures superior conductivity and minimal inclusions

Copper C110 (Electrolytic Tough Pitch)

Electrical conductivity: ~97–100% IACS

Thermal conductivity: ~385 W/m·K

Good corrosion resistance and moderate mechanical strength

Suitable for bus bars, coil windings, thermal plates, and EMI shielding structures

CuCr1Zr (Copper-Chromium-Zirconium Alloy)

Electrical conductivity: ~75–85% IACS

High strength and thermal stability after heat treatment

Used in high-load heat exchangers, electrode holders, and cooling systems for tooling and power electronics

Better printability and mechanical performance compared to pure copper

GRCop-42 (Cu-Cr-Nb Alloy)

Developed for high-heat aerospace and rocket engine components

Superior creep resistance and thermal conductivity at elevated temperatures

Applied in combustion chambers, nozzles, and thrust chamber liners

Customer-Oriented Solutions and Services

To support copper part development with SLM, we provide:

3D Printing Technologies:

Leverage Copper Alloy 3D Printing using optimized SLM parameters for high-density, high-conductivity parts.

Material Options:

Electronics and Thermal Applications:

Explore high-performance use cases in consumer electronics, energy systems, and aerospace, enhanced by CNC machining and surface treatment.