Taking Flight with Innovation: 3D Printed Copper Cooling Systems for Aerospace Electronics

Introduction

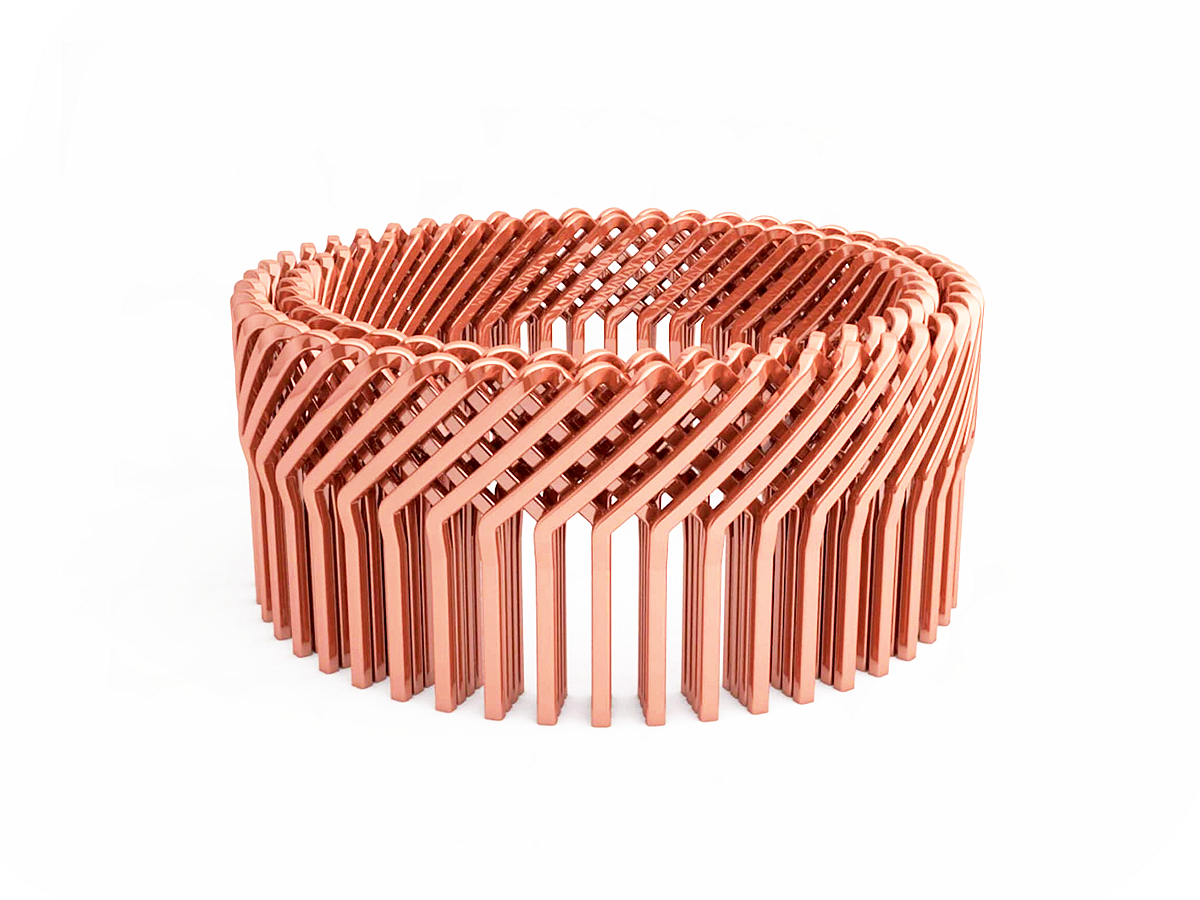

Copper 3D printing is revolutionizing thermal management in aerospace electronics by enabling the creation of lightweight, high-performance cooling systems. Utilizing advanced metal 3D printing technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), aerospace-grade copper alloys like Copper C101 and GRCop-42 offer unparalleled thermal conductivity, making them ideal for compact, high-efficiency electronic cooling solutions in flight systems.

Compared to conventional fabrication methods, copper 3D printing for aerospace cooling systems enables the production of intricate geometries, conformal cooling paths, and optimized thermal designs that improve the reliability and performance of mission-critical aerospace electronics.

Applicable Material Matrix

Material | Electrical Conductivity (% IACS) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Purity (%) | Aerospace Cooling Suitability |

|---|---|---|---|---|---|

≥99 | 390–400 | 220 | 99.99% | Ultra-high conductivity | |

≥97 | 380–390 | 210 | 99.90% | General cooling systems | |

~80 | 275–300 | 350 | Alloyed | High-temperature aerospace cooling | |

75–80 | 300–320 | 450 | Alloyed | Durable thermal management | |

≥99.95 | 390–400 | 200 | 99.95% | Lightweight cooling elements |

Material Selection Guide

Copper C101: Providing unmatched thermal conductivity (up to 400 W/m·K) and high purity, C101 is perfect for high-efficiency cold plates, heat spreaders, and cooling channels in avionics systems.

Copper C110: Balancing cost and performance, C110 is ideal for general-purpose heat sinks and thermal dissipation structures in less extreme aerospace environments.

GRCop-42: Alloyed for improved high-temperature performance and creep resistance, GRCop-42 is the preferred material for spacecraft and jet engine electronic cooling systems operating under severe thermal loads.

CuCr1Zr: With superior mechanical strength and good thermal conductivity, CuCr1Zr is suitable for robust cooling structures supporting mechanical loads in flight applications.

Pure Copper: Used where maximum thermal performance and minimum electrical loss are required, ideal for precision avionics cooling.

Process Performance Matrix

Attribute | Copper 3D Printing Performance |

|---|---|

Dimensional Accuracy | ±0.05 mm |

Density | >99.5% Theoretical Density |

Layer Thickness | 30–60 μm |

Surface Roughness (As-Printed) | Ra 5–12 μm |

Minimum Feature Size | 0.3–0.5 mm |

Process Selection Guide

Conformal Cooling Design: 3D printing enables integrated cooling channels closely following component geometries, significantly improving thermal management efficiency.

High Thermal Conductivity: Materials like C101 and GRCop-42 allow critical aerospace electronics to maintain operational temperatures under extreme flight conditions.

Lightweight Optimization: 3D printed copper cooling systems can include lattice structures and weight-reducing features while maintaining strength and performance.

Rapid Prototyping and Production: Faster development cycles for next-generation aerospace electronics through on-demand copper 3D printing.

Case In-Depth Analysis: GRCop-42 3D Printed Cold Plate for Avionics Cooling

An aerospace contractor required a lightweight, high-efficiency cold plate for a compact avionics package operating in a high-temperature, low-pressure flight environment. Using our copper 3D printing service with GRCop-42, we produced a cold plate with integrated micro-channels, achieving excellent thermal conductivity (~280 W/m·K) and maintaining dimensional tolerances within ±0.05 mm. The solution improved thermal dissipation by 22% compared to conventional machined aluminum cold plates, enabling higher operational reliability and reduced electronic failure rates during flight testing.

Industry Applications

Aerospace and Aviation

Cold plates and heat exchangers for avionics and flight control systems.

High-conductivity thermal spreaders for satellite electronics.

Lightweight cooling structures for UAV electronics and payloads.

Space Systems

Electronics cooling modules for spacecraft and rovers.

Micro-channel heat sinks for spaceborne sensors and communication equipment.

Defense Systems

Thermal management for ruggedized electronics in military aircraft and ground systems.

Mainstream 3D Printing Technology Types for Copper Aerospace Components

Selective Laser Melting (SLM): Best for producing dense, ultra-high-conductivity copper cooling systems with precise geometries.

Direct Metal Laser Sintering (DMLS): Ideal for complex micro-channel cooling structures for compact aerospace electronics.

Binder Jetting: Suitable for cost-effective prototyping and low-volume production of thermal management components.

FAQs

Which copper alloys are best suited for 3D printed aerospace cooling systems?

How does copper 3D printing improve thermal management in aerospace electronics?

What are the benefits of conformal cooling designs in 3D printed copper structures?

Can 3D printed copper cooling systems withstand high-temperature aerospace environments?

How does copper 3D printing accelerate prototyping and deployment of flight electronics cooling systems?