Which industries use three-dimensional printed copper for advanced applications?

Which Industries Use 3D Printed Copper for Advanced Applications?

Aerospace and Aviation

3D printed copper is widely used in the aerospace sector for components requiring high thermal conductivity and structural integrity under extreme conditions. Applications include combustion chamber liners, regenerative cooling channels, and RF waveguides. Alloys like GRCop-42 and Pure Copper, printed via EBM or LMD, deliver the necessary heat transfer performance and geometrical freedom for lightweight, integrated systems.

Consumer Electronics

In the consumer electronics industry, copper 3D printing supports the development of complex EMI/RFI shielding enclosures, thermal interface components, and precision antennas. Copper C110 and C101 are ideal for miniaturized and conductive parts that must be produced rapidly during prototyping or low-volume production cycles.

Energy and Power Systems

3D printed copper enables the fabrication of high-efficiency power distribution components such as busbars, induction coils, and thermal exchangers. The superior electrical conductivity of Copper C101 (up to 391 W/m·K) ensures minimal energy losses and stable performance under high load conditions. Complex internal cooling geometries, previously impossible to machine, are now achievable through DMLS.

Medical Devices

In the medical industry, 3D printed copper is used in applications requiring both antimicrobial properties and thermal conductivity. Examples include surgical tool inserts, customized heat spreaders for diagnostic devices, and shielding for sensitive electronic instruments. Pure Copper and CuCr1Zr offer the right balance between formability and performance.

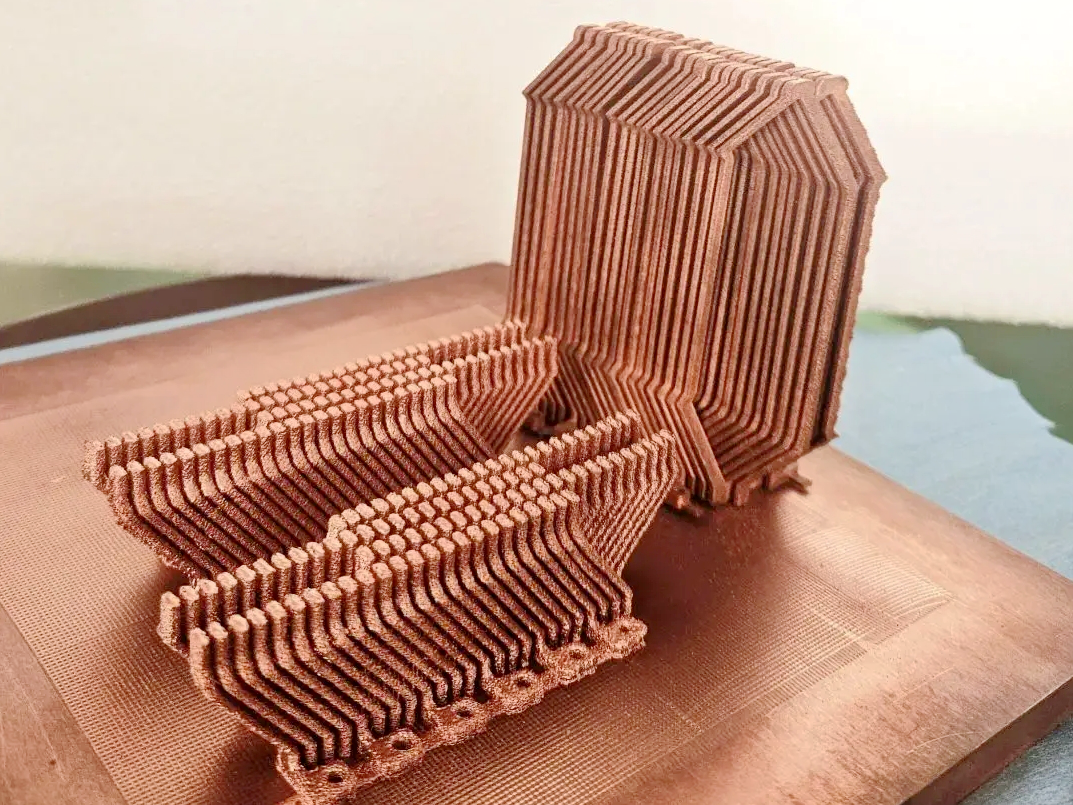

Industrial and Robotics

The industrial automation and robotics fields leverage copper additive manufacturing to create compact, performance-critical components such as motor windings, precision heat sinks, and electromagnetic shielding structures. The ability to consolidate parts and integrate multiple functions into a single copper structure reduces weight, size, and assembly time in complex electromechanical systems.

Relevant Copper 3D Printing Services from Neway

Material-Specific Copper Printing: Utilize high-conductivity materials such as C101, C110, and GRCop-42 with powder bed fusion or directed energy deposition.

Application-Specific Post-Processing: Enhance thermal and electrical function through HIP, electropolishing, and CNC finishing.

Industry-Aligned Design Support: Access professional support tailored to demanding industries like aerospace, consumer electronics, and energy and power for optimized copper component design.