What is the role of copper alloys in additive manufacturing for automotive components?

What Is the Role of Copper Alloys in Additive Manufacturing for Automotive Components?

Thermal Management for Electrified Powertrains

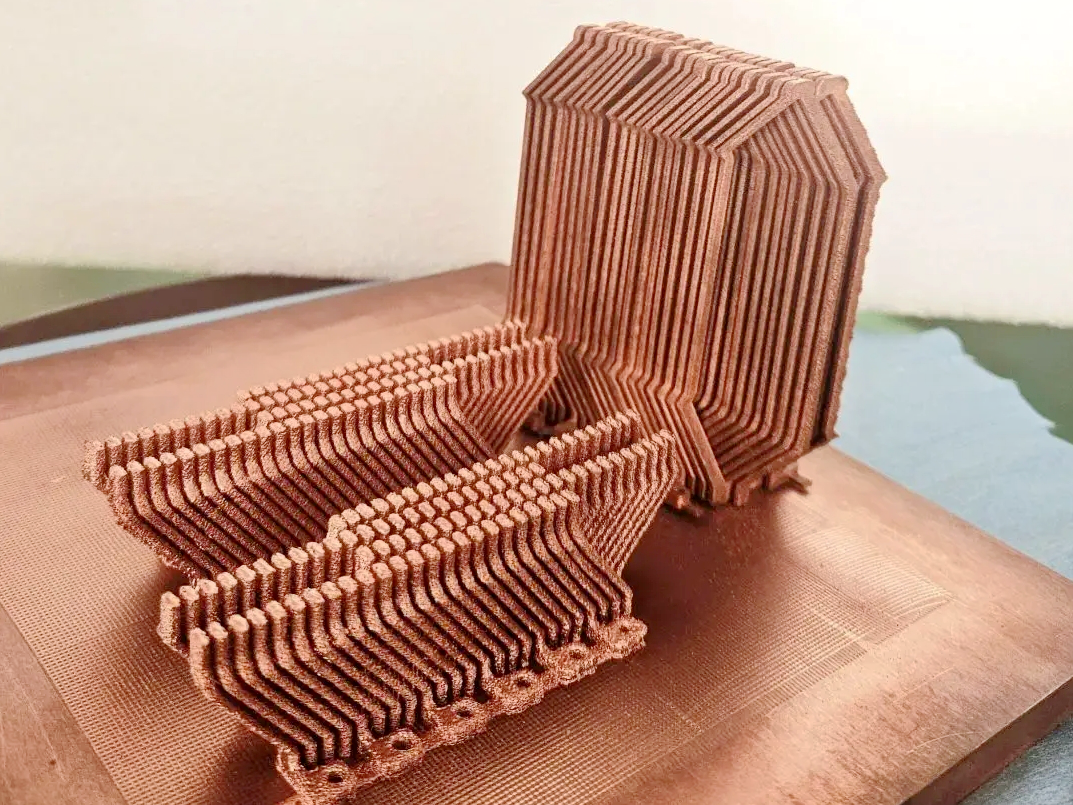

Copper alloys play a critical role in additive manufacturing (AM) for automotive applications that require high thermal conductivity. Materials like Copper C110 and CuCr1Zr are commonly used to produce heat sinks, cold plates, and integrated cooling systems in electric vehicle (EV) battery packs, inverters, and power electronics. Additive manufacturing allows conformal cooling channels and complex fin geometries that significantly improve heat dissipation efficiency.

Electrical Conductivity in Power Distribution

With the rise of vehicle electrification, copper alloys are essential for producing high-conductivity electrical components such as bus bars, terminals, and contactor housings. Additive manufacturing enables compact, custom-fit geometries that optimize current pathways and reduce electrical losses. Alloys like Copper C101 offer conductivity exceeding 100% IACS, ensuring minimal resistance in high-voltage circuits.

Lightweight Design and Part Integration

Using technologies like Selective Laser Melting (SLM) and Binder Jetting, copper alloys can be printed into optimized geometries with integrated functions. This supports lightweighting strategies by consolidating multiple parts into a single, efficient component, such as a combined cooling manifold and electrical conductor, reducing both mass and assembly complexity.

Wear and Corrosion Resistance

Copper-chromium-zirconium alloys like CuCr1Zr combine good thermal conductivity with improved strength and corrosion resistance. These are ideal for moving contact components, bearing surfaces, or thermal interfaces exposed to vibration, moisture, and temperature cycling in underhood or exterior environments.

Customer-Oriented Solutions and Services

To support copper alloy part production for automotive applications, we offer:

3D Printing Technologies:

Use our Copper Alloy 3D Printing capabilities with SLM and Binder Jetting for conductive, thermal, and structural performance.

Copper Alloy Material Options:

Automotive Application Support:

Explore our full automotive manufacturing solutions, including CNC machining, surface treatment, and heat treatment for copper-based components.