What is the role of stainless steel alloys in additive manufacturing for automotive components?

What Is the Role of Stainless Steel Alloys in Additive Manufacturing for Automotive Components?

Corrosion Resistance and Durability in Harsh Environments

Stainless steel alloys such as SUS316L and SUS304 are widely used in automotive additive manufacturing for components exposed to heat, moisture, chemicals, and road salts. Their superior corrosion resistance ensures long-term performance for exhaust parts, brackets, housings, and structural reinforcements, especially in high-humidity or coastal applications.

Strength and Fatigue Resistance for Load-Bearing Parts

High-strength stainless steel grades like 17-4 PH and 15-5 PH are ideal for automotive parts that require excellent mechanical performance under cyclic loads. These alloys offer tensile strengths above 1,000 MPa and maintain dimensional stability after heat treatment, making them suitable for suspension linkages, powertrain mounts, and drivetrain supports.

Precision and Lightweight Optimization

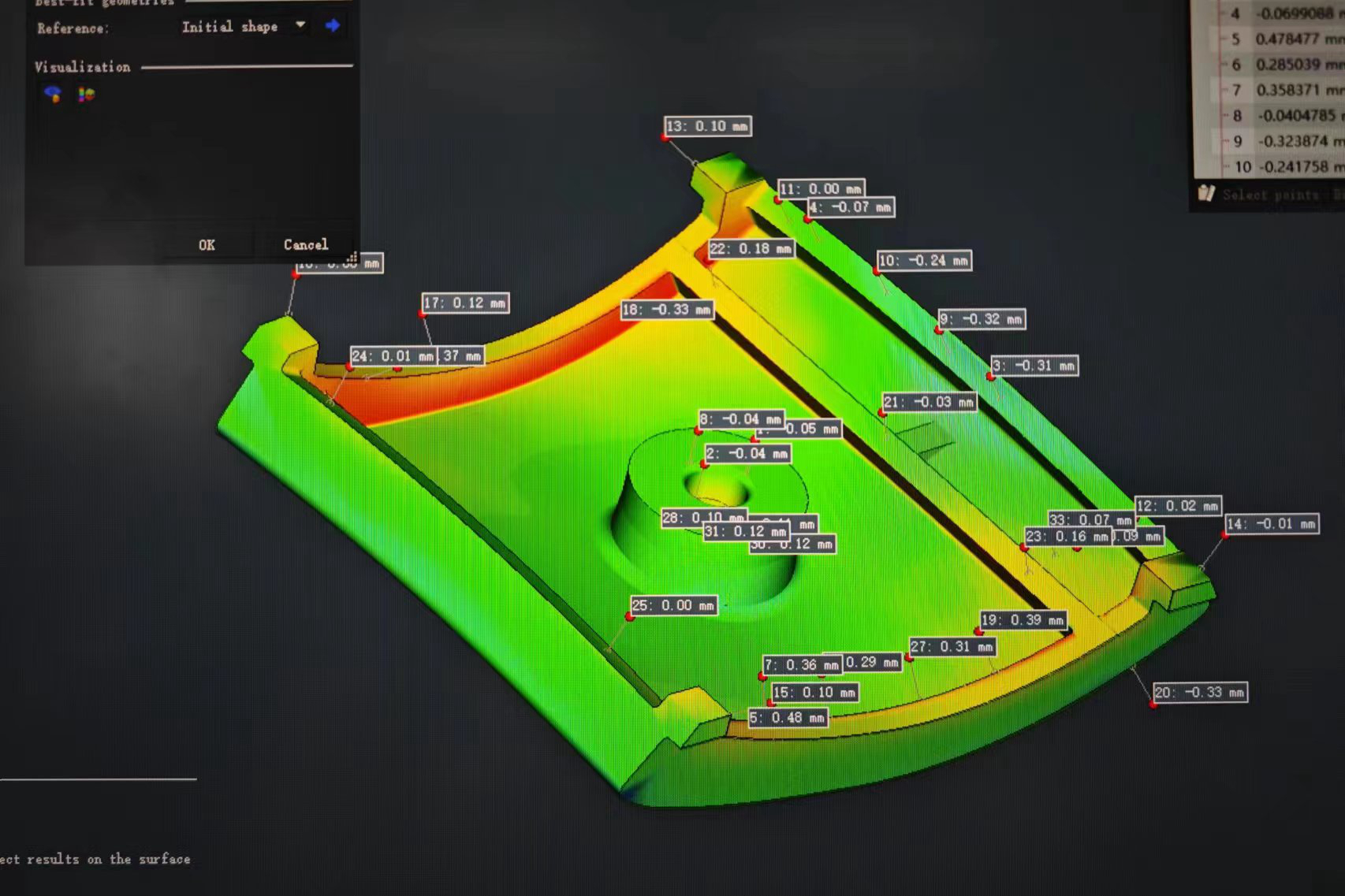

Using technologies like Selective Laser Melting (SLM), stainless steel can be additively manufactured into highly complex, weight-optimized geometries with integrated functions. Automotive engineers utilize this design freedom for lattice-supported brackets, heat exchangers, and integrated sensor housings that combine mechanical strength with reduced material usage.

High-Temperature Stability

Stainless steel’s thermal resistance, especially in grades like SUS410 and SUS420, supports use in engine bay components, turbocharger housings, and exhaust flanges. These alloys maintain mechanical properties at elevated temperatures, enabling safe and reliable operation under continuous thermal cycling.

Customer-Oriented Solutions and Services

To support stainless steel AM for automotive components, we offer:

3D Printing Technologies:

Leverage Stainless Steel 3D Printing with SLM and Binder Jetting for complex, high-performance parts.

Material Selection:

Automotive Industry Support:

Explore our automotive solutions, supported by heat treatment, CNC machining, and surface treatment for ready-to-install components.