How does HIP enhance structural integrity in metal or ceramic components?

How Does HIP Enhance Structural Integrity in Metal or Ceramic Components?

Near-Full Densification of Internal Structures

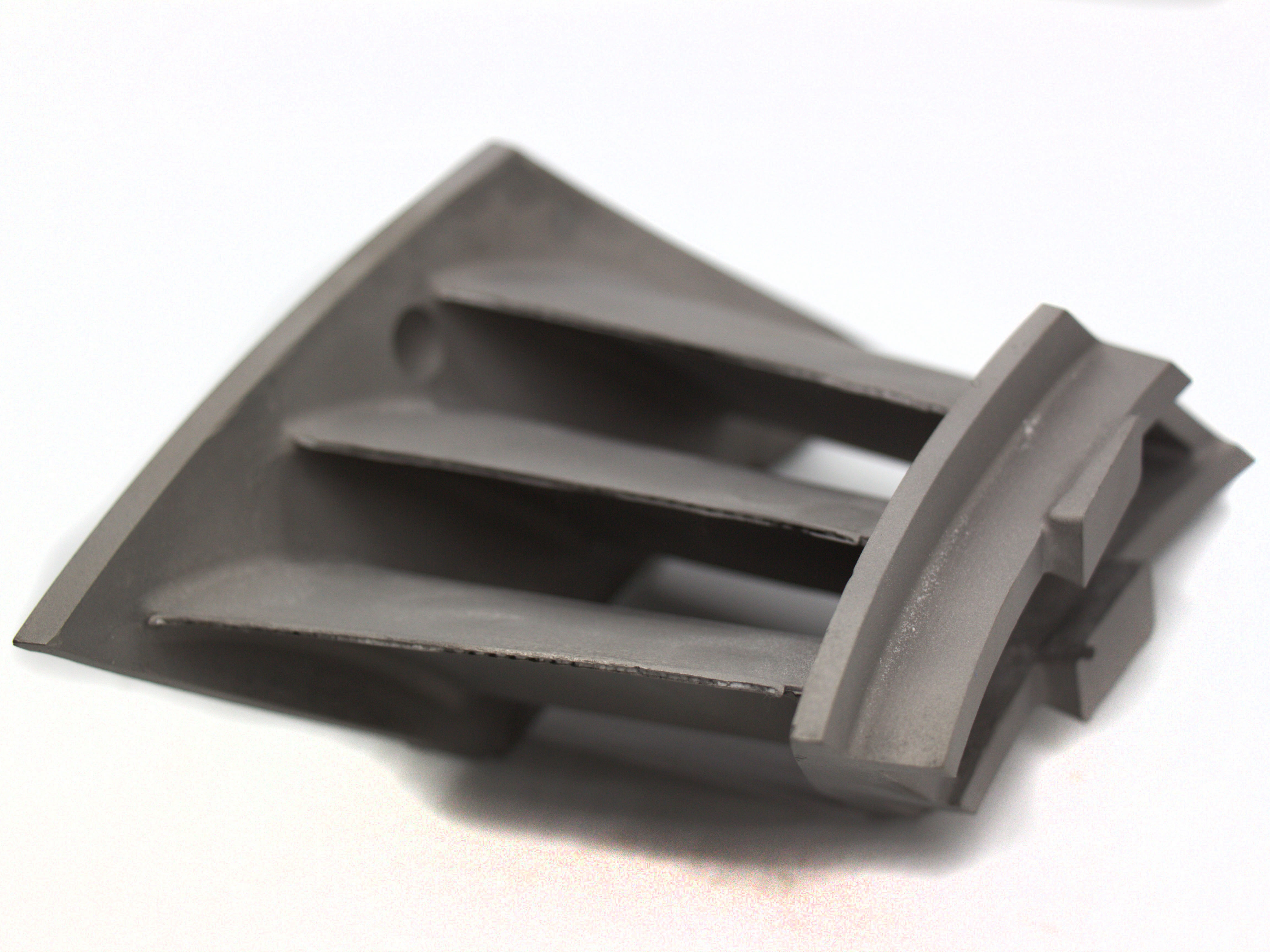

Hot Isostatic Pressing (HIP) significantly enhances structural integrity by eliminating internal voids and microdefects common in metal and ceramic 3D printed parts. Through the application of high-pressure gas (up to 200 MPa) and elevated temperatures (900–1250°C for metals, and up to 1800°C for ceramics), HIP promotes atomic diffusion across pore boundaries, collapsing internal porosity and achieving near-100% theoretical density. This is critical in load-bearing parts produced by Powder Bed Fusion, Binder Jetting, or Ceramic 3D Printing.

For example, components made from Stainless Steel SUS316L, Inconel 625, or Zirconia demonstrate increased resistance to crack propagation and structural collapse after HIP treatment.

Microstructural Homogenization and Crack Healing

HIP contributes to microstructure uniformity by reducing residual stresses and promoting grain refinement or controlled grain growth. In metal parts such as Tool Steel H13 or Ti-6Al-4V, this enhances load transfer capability and reduces anisotropic mechanical behavior.

In ceramics, HIP is especially effective for Alumina, Silicon Nitride, and Silicon Carbide, where it improves flexural strength, thermal shock resistance, and eliminates sintering-related flaws that compromise reliability in high-stress thermal or mechanical environments.

Improved Performance Under Thermal, Mechanical, and Pressure Loads

By removing defect clusters and ensuring structural continuity, HIP enhances performance under mechanical load, vibration, and thermal cycling. Aerospace turbine blades, nuclear fuel cladding, and medical implants benefit from extended lifespan and failure resistance post-HIP.

Recommended Services for Structural Integrity Enhancement

Neway offers integrated solutions to maximize structural reliability in critical components:

Material-Specific 3D Printing Services:

Metal 3D Printing: Covers high-performance alloys, steels, and titanium components.

Ceramic 3D Printing: Produces complex, high-strength ceramic geometries for technical applications.

Densification and Strengthening Post-Processes:

Hot Isostatic Pressing (HIP): Achieves full density, crack closure, and structural consolidation.

Heat Treatment: Tailors hardness, ductility, and grain structure post-HIP.

Surface and Precision Enhancement:

CNC Machining: Delivers final surface precision and dimensional control.

Electropolishing: For improved fatigue and corrosion resistance in metal parts.