Zirconia (ZrO2)

Zirconia (ZrO₂) is a high-performance oxide ceramic known for outstanding fracture toughness, biocompatibility, and wear resistance. It is ideal for demanding applications where strength, thermal insulation, or chemical stability is essential.

Through ceramic 3D printing, zirconia is used to fabricate dental restorations, cutting tool inserts, and structural industrial parts. Additive manufacturing enables miniaturization, complex internal channels, and high-quality surface finishes previously unattainable through conventional methods.

Zirconia Similar Grades Table

Grade Type | Stabilizer | Typical Application |

|---|---|---|

3Y-TZP (3 mol% Yttria) | Y₂O₃ (3%) | Dental crowns, implants, wear-resistant parts |

5Y-PSZ (5 mol% Yttria) | Y₂O₃ (5%) | Translucent dental ceramics, aesthetic parts |

Mg-PSZ (Magnesia stabilized) | MgO | Thermal barrier coatings, industrial linings |

Ce-TZP (Ceria stabilized) | CeO₂ | Impact-resistant components |

Zirconia Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 5.95–6.10 g/cm³ |

Melting Point | ~2700°C | |

Thermal Conductivity (25°C) | 2.0–3.0 W/(m·K) | |

Electrical Resistivity (25°C) | >10¹² Ω·cm | |

Thermal Expansion (25–1000°C) | 10.5 µm/(m·K) | |

Mechanical Properties | Hardness (Vickers) | 1200–1400 HV |

Flexural Strength | 900–1200 MPa | |

Fracture Toughness (K₁C) | 7–10 MPa·m½ | |

Compressive Strength | ≥2000 MPa | |

Elastic Modulus | 200–210 GPa |

3D Printing Technology of Zirconia

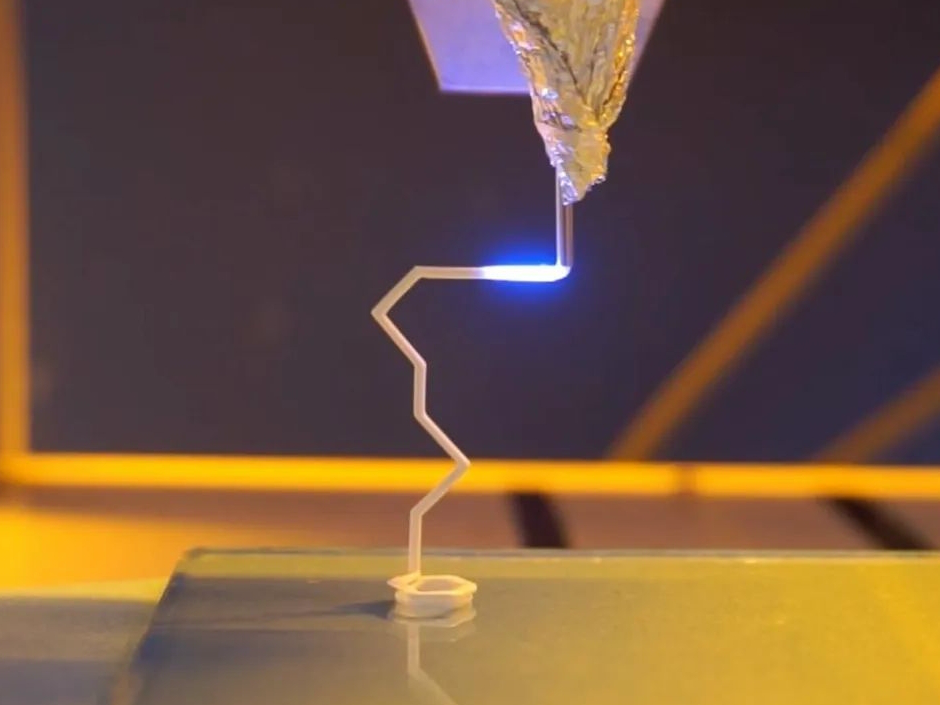

Zirconia is 3D printed using Vat Photopolymerization (VPP), Material Jetting, and Binder Jetting, followed by debinding and sintering. These methods deliver fine feature resolution, high density, and excellent structural accuracy.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

Vat Photopolymerization (VPP) | ±0.05–0.2 mm | Excellent | Excellent | Dental, Medical, Precision Parts |

Material Jetting | ±0.1–0.3 mm | Very Good | Good | Valves, Wear Parts, Thermal Insulators |

Binder Jetting | ±0.1–0.3 mm | Good | Moderate | Industrial Ceramics, Prototypes |

Zirconia 3D Printing Process Selection Principles

VPP is the top choice for high-precision parts such as dental prosthetics and surgical tools, achieving tolerances of ±0.05–0.2 mm and surface roughness < Ra 2 µm after sintering.

Material Jetting provides a balance between throughput and detail, ideal for producing small-to-medium batches of components like valve seals and ceramic bushings.

Binder Jetting is effective for larger components and lower-cost ceramic prototypes, offering good shape fidelity after controlled sintering.

Zirconia 3D Printing Key Challenges and Solutions

Shrinkage during sintering (typically 20–25%) requires CAD scaling and process compensation. Iterative sintering profiles minimize warping and maintain dimensional accuracy.

Porosity and strength loss are mitigated using high solid-loading slurries or powders and optimized debinding cycles. Achievable densities exceed 98% of theoretical, delivering full mechanical performance.

Surface flaws and microcracks can result from improper drying or temperature ramping. Carefully controlled thermal profiles and post-sinter polishing reduce Ra to ≤1.0 µm, suitable for dental and biomedical use.

Zirconia materials must be kept free from humidity to avoid phase transformation; sealed environments and RH < 40% during drying are essential.

Industry Application Scenarios and Cases

Zirconia 3D printing is used in:

Medical and Dental: Crowns, bridges, surgical guides, biocompatible implants.

Industrial: Pump seals, thermal insulators, wear plates, nozzles.

Aerospace: High-strength spacers, electrical isolators, heat shields.

In a recent dental application, VPP-printed 5Y-PSZ zirconia crowns achieved sub-±50 µm accuracy and aesthetic translucency, enabling delivery within 48 hours compared to 5-day milling lead times.

FAQs

What are the benefits of using Zirconia over Alumina in 3D printing?

Which zirconia grades (3Y, 5Y, Mg-PSZ) are best for dental and industrial use?

What post-processing is needed for 3D printed zirconia parts?

How does shrinkage affect part accuracy in zirconia additive manufacturing?

What are typical applications for zirconia components in medical and aerospace industries?