Silicon Nitride (Si3N4)

Silicon Nitride (Si₃N₄) is a lightweight technical ceramic known for its exceptional fracture toughness, thermal shock resistance, and high strength up to 1200°C. It is ideal for structural, aerospace, and wear-critical components under severe operating conditions.

Using ceramic 3D printing, Si₃N₄ parts can be produced with complex geometries and reduced lead times. Additive manufacturing supports advanced applications such as turbine rotors, bearings, and electronic insulators with high reliability and performance.

Silicon Nitride Similar Grades Table

Grade Type | Composition | Typical Applications |

|---|---|---|

Gas Pressure Sintered (GPS-Si₃N₄) | High-purity Si₃N₄ | Bearings, turbine wheels, insulators |

Reaction-Bonded (RBSN) | Si + N₂ reaction | Complex thermal structures, kiln furniture |

Hot-Pressed (HP-Si₃N₄) | Dense, fine-grain | Aerospace, wear-resistant tooling |

Silicon Nitride Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 3.20–3.25 g/cm³ |

Melting Point | Decomposes >1900°C | |

Thermal Conductivity (25°C) | 15–30 W/(m·K) | |

Thermal Expansion (25–1000°C) | 3.0 µm/(m·K) | |

Electrical Resistivity (25°C) | >10¹³ Ω·cm | |

Mechanical Properties | Hardness (Vickers) | 1400–1600 HV |

Flexural Strength | 600–1000 MPa | |

Compressive Strength | ≥3000 MPa | |

Elastic Modulus | 280–320 GPa | |

Fracture Toughness (K₁C) | 5–7 MPa·m½ |

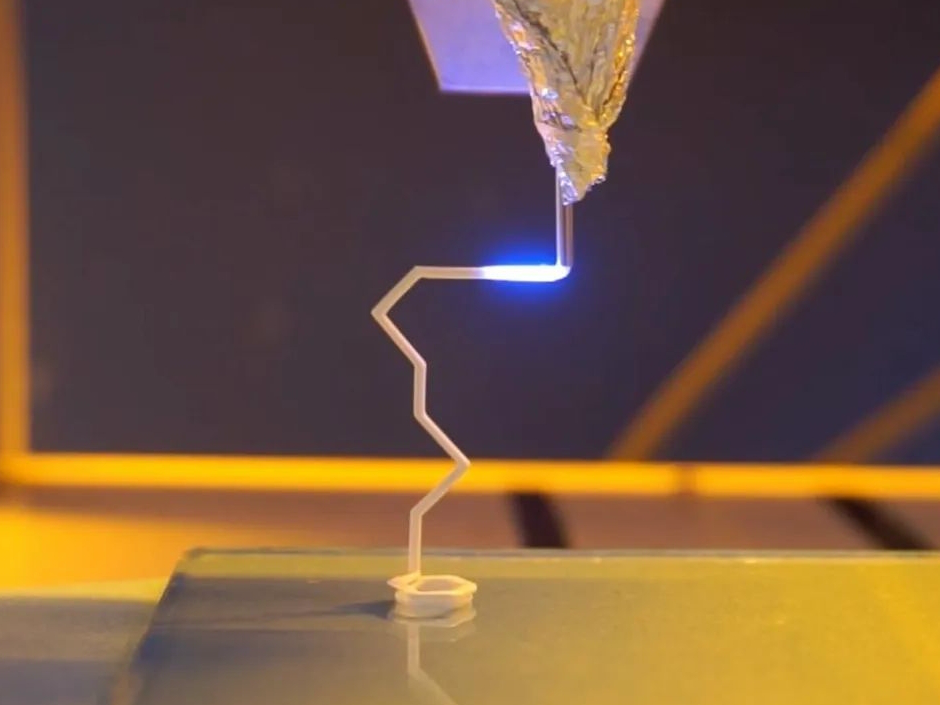

3D Printing Technology of Silicon Nitride

Si₃N₄ is primarily 3D printed using Vat Photopolymerization (VPP) and Binder Jetting. Both require debinding and sintering to achieve full ceramic properties. Emerging technologies also explore laser-assisted and hybrid additive manufacturing routes.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

VPP | ±0.05–0.2 mm | Excellent | Excellent | Bearings, Medical Tools, Microstructures |

Binder Jetting | ±0.1–0.3 mm | Good | Very Good | Structural Parts, Wear Components |

Silicon Nitride 3D Printing Process Selection Principles

Vat Photopolymerization (VPP) is ideal for high-precision Si₃N₄ components such as surgical tool inserts, bearing cages, and insulation pins with Ra < 2 µm and fine lattice structures.

Binder Jetting supports large or complex components like rotor blades, electronic housings, or support frames, providing cost-effective fabrication with strong mechanical properties after sintering.

Silicon Nitride 3D Printing Key Challenges and Solutions

Shrinkage (15–25%) during sintering requires careful pre-compensation and accurate thermal modeling. Optimized sintering profiles minimize distortion and deliver parts with >98% theoretical density.

Porosity and thermal cracking risks are managed through controlled debinding and particle size distribution. Dense sintered bodies ensure excellent thermal shock and wear resistance.

Surface roughness (Ra 8–15 µm) can be improved via post-sinter polishing or CNC machining, achieving Ra ≤1.0 µm for demanding sealing or bearing applications.

Si₃N₄ powder must be kept dry and oxygen-free (RH < 40%) to prevent oxidation or degradation before printing.

Industry Application Scenarios and Cases

Silicon Nitride 3D printing is used in:

Aerospace: Turbine rotors, shrouds, and insulating rings for high-speed environments.

Medical: Surgical blades, anti-bacterial dental tools, and implantable insulating materials.

Industrial: Bearing rollers, wear nozzles, fixture plates, and electronic insulators.

In a turbine application, 3D printed Si₃N₄ shrouds replaced cast parts, reducing weight by 30% and extending operational temperature limits to 1200°C with no structural degradation after 1000 cycles.

FAQs

What are the advantages of Silicon Nitride over other ceramic materials in 3D printing?

Which 3D printing methods are suitable for fabricating high-strength Si₃N₄ components?

How is shrinkage and warping managed in Si₃N₄ ceramic sintering?

What post-processing steps are required for functional Si₃N� components?

What industries benefit most from 3D printed Silicon Nitride parts?