How does Electron Beam Melting (EBM) benefit copper parts for aerospace applications?

How Does Electron Beam Melting (EBM) Benefit Copper Parts for Aerospace Applications?

High Thermal Conductivity for Heat-Intensive Components

Electron Beam Melting (EBM) is particularly beneficial for producing aerospace-grade copper parts that require superior thermal conductivity. Materials such as Copper C101 and GRCop-42 are well-suited for EBM due to their high-energy beam and vacuum environment, which reduces oxidation and enables the fabrication of dense copper components with conductivity exceeding 380 W/m·K. This is ideal for critical systems such as thermal management structures, heat exchangers, and combustion chamber linings.

Vacuum Processing Enhances Purity and Surface Quality

Copper's high reflectivity and oxidation sensitivity make it difficult to process using laser-based systems in atmospheric conditions. EBM’s vacuum chamber prevents oxidation and hydrogen embrittlement, resulting in high-purity parts with improved electrical and thermal performance. This is crucial in aerospace applications such as RF components, power electronics cooling plates, and engine components, where material purity directly impacts efficiency.

Superior Performance at Elevated Temperatures

Copper parts in aerospace are often exposed to extreme thermal loads. Alloys like GRCop-42, designed for high-temperature applications, retain mechanical strength and resist creep at temperatures exceeding 600°C. EBM enables uniform grain structures and stable microstructures that support thermal fatigue resistance, essential for propulsion system components and engine nozzle liners.

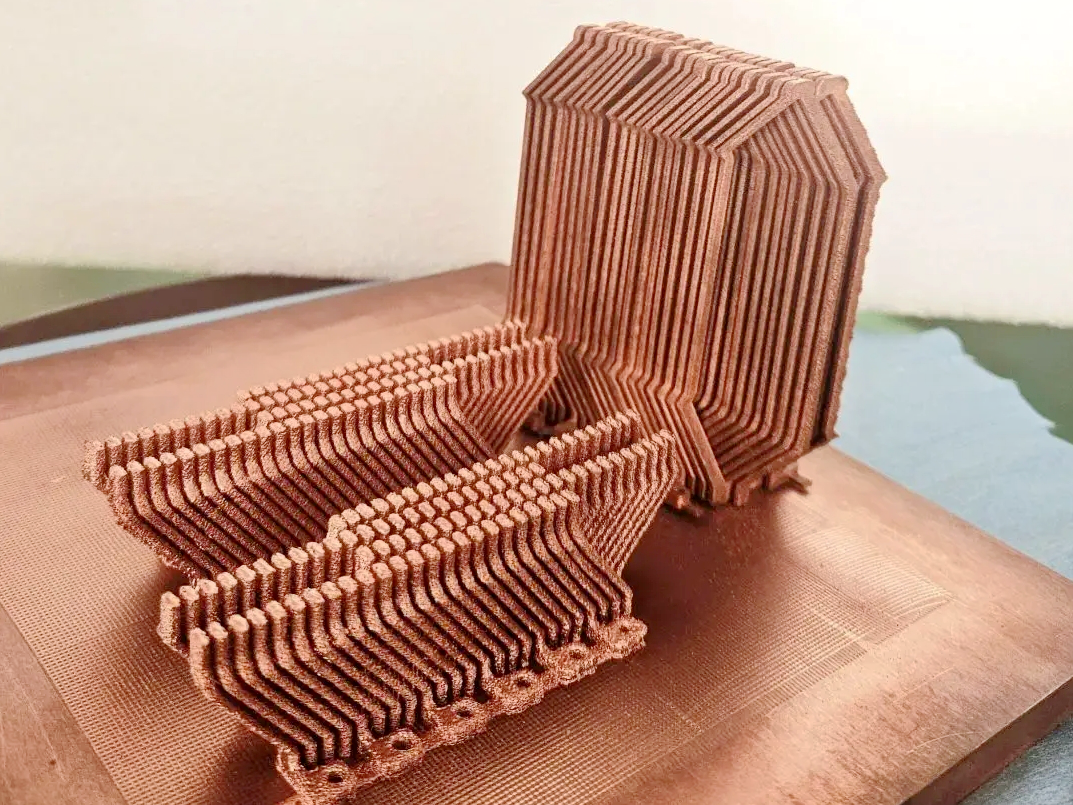

Complex Geometry for Weight Optimization

EBM supports the production of complex geometries, such as lattice-structured heat sinks, thin-wall channels, and conformal cooling networks. This allows engineers to optimize part weight without sacrificing thermal performance, especially important in aerospace designs where every gram affects fuel efficiency and payload.

Customer-Oriented Solutions and Services

We support copper AM for aerospace with the following:

3D Printing Technologies:

Leverage Electron Beam Melting (EBM) for vacuum-based, high-conductivity copper parts with superior thermal integrity.

Aerospace-Grade Copper Materials:

Choose from Copper C101, CuCr1Zr, and GRCop-42 for heat transfer, structural, and propulsion applications.

Aerospace Application Support:

Explore our aerospace and aviation solutions, supported by heat treatment, CNC machining, and surface treatment for mission-critical components.