OES Direct Reading: Rapid Alloy Conformity for Serial AM

Introduction: A Promise in Minutes – How OES Spark Spectrometry Builds a Material Consistency Shield for Serial AM Production

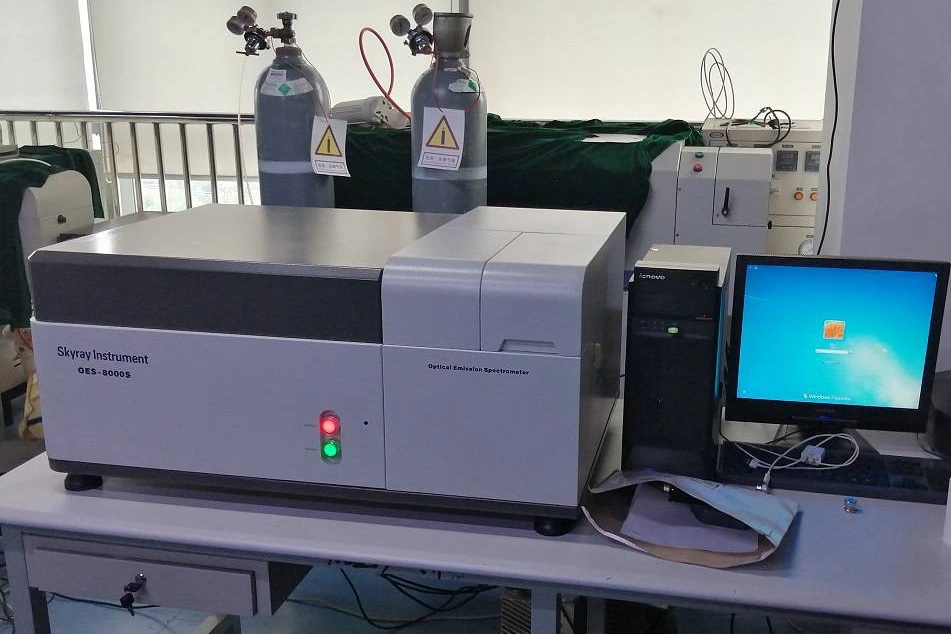

In serial additive manufacturing, material consistency is not just a technical metric; it is the lifeline that determines product reliability. As materials analysis engineers at Neway, we have witnessed numerous batch issues triggered by seemingly minor deviations in material composition. Traditional chemical analysis methods can take days to deliver results—an unacceptable delay for modern serial production. In response to this challenge, we introduced Optical Emission Spectrometry (OES) with direct reading capability, reducing the material verification cycle from days to minutes and establishing a real-time quality barrier for materials used in serial production.

What Is OES Direct-Reading Spectrometry?

Working Principle: Spark Discharge and Elemental Fingerprints

The core principle of OES direct-reading spectrometry is based on atomic emission. When a sample is excited under spark discharge, different elements emit characteristic spectral lines at specific wavelengths. These emissions are dispersed by a high-precision optical system and detected by a photomultiplier or solid-state detector array. Each element has its own unique "spectral fingerprint." By measuring the intensity of these characteristic lines, we can accurately determine the concentration of each element in the sample. The entire process is fast and precise, providing a robust technological foundation for chemical composition analysis.

Technical Advantages: Speed, Accuracy, and Coverage

OES technology excels in three key aspects. In terms of speed, it typically takes only 1–2 minutes from sample preparation to result output—far beyond the efficiency of traditional wet chemical analysis. In terms of accuracy, detection limits for most metallic elements can reach the ppm level, fully meeting the demands of high-end industries such as aerospace. In terms of coverage, our system can simultaneously analyze dozens of elements, including carbon, sulfur, and phosphorus, providing comprehensive support for material composition verification.

How Neway Integrates OES Direct Reading into the Serial AM Quality Control Chain

Fast Screening of Metal Powder Incoming Batches – Eliminating Deviations at the Source

At the material receiving stage, we perform rigorous OES composition verification for every batch of metal powder. By comparing test results against supplier mill certificates, we ensure full conformity in elemental composition. These strict incoming inspection forms a solid foundation for the quality of our 3D printing services. In practice, we have repeatedly identified off-spec materials through this rapid screening step and successfully prevented them from entering production.

In-Process Sampling Monitoring to Flag Cross-Contamination

During serial production, we periodically analyze recycled powder and printed witness coupons. This monitoring effectively identifies potential contamination issues, such as wear particles from equipment or cross-contamination between different powder batches. By correlating powder usage cycles with compositional changes, we establish scientific criteria for powder replacement and disposal, ensuring process stability and consistent production quality.

Finished Part Composition Verification – Closing the Quality Loop

For final parts, we perform sampling-based composition checks to confirm that the actual chemical composition meets applicable specifications for industries such as aerospace. This closed-loop control approach ensures full traceability from raw materials to finished components and provides a comprehensive, data-backed foundation for product quality assurance.

Key Applications of OES in Assuring Material Consistency for AM

Accurate Alloy Grade Identification – Preventing Mix-Ups

In serial production, unintentional mixing of different alloys can have catastrophic consequences. OES can rapidly and reliably distinguish visually similar alloys, such as 304 stainless steel and 316 stainless steel, or different grades of titanium alloys. This fast identification capability effectively prevents material mix-up incidents caused by human error and ensures correct alloy usage on the shop floor.

Monitoring Critical Trace Elements to Predict Performance

For high-temperature alloys such as Inconel 718, the contents of key elements like Nb, Al, and Ti have a direct impact on performance. Using OES to precisely monitor these elements, we can anticipate phase transformation behavior during heat treatment and ensure that final parts achieve the desired mechanical properties.

Verifying Material Cleanliness – Supporting Failure Analysis

When abnormal performance is observed, OES can quickly screen for unexpected elemental presence. These results provide crucial guidance for in-depth failure analysis, helping us rapidly narrow down potential causes and implement effective corrective actions.

"Rapid Compliance" – Transformative Value for Serial AM Production

The application of OES direct-reading spectrometry brings significant benefits to serial production. First, it reduces release lead time from several days to just a few minutes, greatly accelerating production flow. Second, by enabling high-frequency or 100% batch verification, it virtually eliminates the risk of out-of-spec material entering critical production. Most importantly, by establishing life-cycle composition monitoring for powders and materials, we can manage consumption and reuse more scientifically, maximizing material utilization while maintaining strict quality assurance.

Synergy Between OES and Other Material Analysis Technologies

Complementarity with Carbon/Sulfur Analyzers

In our analytical system, OES works in close coordination with carbon-sulfur analyzers. OES is responsible for the rapid determination of most metallic elements, while the C/S analyzer specializes in high-precision quantification of carbon and sulfur. Together, they form a comprehensive solution for chemical composition analysis.

Providing Compositional Context for Mechanical Test Results

When results from mechanical testing appear abnormal, OES composition data is often the first basis for investigation. By correlating chemistry with mechanical performance, we can quickly determine whether deviations are driven by compositional issues and provide clear direction for process or material adjustments.

Acting as a Front-End Tool for Metallographic Analysis

Before performing metallographic analysis, OES can rapidly determine whether abnormal microstructures are likely related to segregation or compositional contamination. This combined approach improves diagnostic efficiency and accuracy, offering stronger technical support for root-cause analysis and continuous improvement.

Case Study: How OES Intercepted a Mislabeled Batch of Ti-6Al-4V Powder

In a medical implant project, we received a batch of metal powder labeled as Ti-6Al-4V. Following our standard procedure, we conducted OES verification before warehousing. The results were alarming: aluminum content was significantly lower than expected, vanadium content was abnormally high, and iron—absent from the specified grade—was detected. Further analysis indicated that the actual composition was closer to Ti-6Al-6V-2Sn.

This discovery triggered our emergency response: the entire batch was immediately quarantined. Subsequent investigation revealed a labeling error at the supplier’s packaging line. Had this powder been used for medical implants, it would have resulted in non-compliant products and potentially serious risks to patient safety. Timely interception by OES not only prevented a major incident but also protected our customer from significant economic and reputational damage.

Conclusion: Precise Elemental Control, Secure Batch-Level Stability

OES direct-reading spectrometry has become an indispensable tool for quality assurance in serial additive manufacturing. At Neway, we firmly believe that "quality originates from design, and is safeguarded by every batch of material." Through this fast and precise analytical technology, we establish a robust guarantee of material consistency for each production run. We are convinced that only by exercising strict control over material chemistry can we deliver truly reliable products. We sincerely invite partners committed to elevating serial production quality and efficiency to experience our data-driven material assurance system.

Frequently Asked Questions

How much sample is required for OES analysis, and are there any special preparation requirements?

What are your OES calibration intervals and reference standards for traceability?

What is the typical turnaround time from submitting a sample to receiving an OES test report?

Can OES reliably distinguish pure copper from different copper alloys?