Carbon–Sulfur Analyzer: Fast C/S Compliance for AM Metal Lots

Introduction: Element-Level Quality Control – How Carbon and Sulfur Analysis Ensures Batch Consistency in Metal 3D Printing

In the field of metal additive manufacturing, material purity directly determines the performance of the final parts. As quality control engineers at Neway, we have a deep understanding in our daily work that controlling the content of carbon and sulfur is a key step to ensuring batch consistency in metal 3D printing. Especially in high-demand sectors such as aerospace and medical devices, even minor variations in C/S levels can result in significant differences in part performance. Based on this understanding, we have implemented advanced carbon and sulfur analysis technology to provide fast and accurate elemental analysis solutions for the additive manufacturing process, ensuring every shipped part meets the most stringent quality standards.

Overview of Carbon and Sulfur Analysis Technology

Basic Working Principle

Carbon and sulfur analyzers operate based on the principle of high-frequency combustion and infrared absorption. When a metal sample is combusted in a high-temperature oxygen stream, the carbon present is converted into carbon dioxide, and sulfur into sulfur dioxide. Built-in infrared detectors precisely measure the concentrations of these gases and convert them into corresponding percentages of carbon and sulfur content. This method offers extremely high sensitivity and accuracy, covering a detection range from parts per million (ppm) levels to percentage levels, with a single analysis taking only 40–60 seconds—perfectly aligned with the fast-paced demands of industrial production.

Why Are C/S Levels So Critical for Metal 3D Printing?

In metal 3D printing, subtle fluctuations in carbon content directly affect mechanical properties. For example, in tool steels, an increase of just 0.1% carbon can raise hardness by 2–3 HRC units, while simultaneously reducing toughness. For superalloy materials, sulfur is particularly detrimental—even 50 ppm of sulfur can form brittle sulfides at grain boundaries, significantly decreasing long-term strength at high temperatures. Similarly, in stainless steel additive manufacturing, excessive sulfur content severely compromises corrosion resistance and service life.

How Neway Integrates Carbon and Sulfur Analysis into Metal Powder Quality Management

Incoming Inspection: Ensuring Raw Material Purity

We have established a rigorous workflow for inspecting raw materials. Every batch of newly purchased metal powder must pass carbon and sulfur analysis before being accepted into inventory. Our acceptance criteria are often stricter than industry standards. For example, for aerospace-grade Inconel 718 powder, we require sulfur content to be below 30 ppm, whereas the typical industry limit is 50 ppm. This strict front-end control ensures the purity of production feedstock and lays a solid foundation for subsequent print quality.

Process Monitoring: Tracking the Powder Lifecycle

During powder usage, we regularly perform carbon and sulfur analysis on recycled powders. By comparing data trends between virgin and reused powder, we can accurately assess powder aging and take timely actions such as adjusting process parameters or replacing powder. For instance, if we detect a continuous increase in carbon content, it may indicate issues in the protective atmosphere during printing, prompting immediate checks of equipment sealing. This ongoing monitoring effectively prevents batch quality issues caused by powder degradation.

Batch Release: Providing Assurance for Final Product Quality

Only powder batches with carbon and sulfur contents fully meeting specifications are approved for production. For critical applications—such as those used in the aerospace and medical sectors—we enforce even stricter release criteria. Each released batch is backed by complete analytical records, which are ultimately integrated into the parts’ quality documentation, providing customers with a full traceability chain.

"Fast Compliance" – Core Value for AM Production Processes

Accelerated Production Decisions and Shortened Lead Times

Traditional third-party lab testing often takes 3–5 working days to deliver results, whereas our in-house carbon and sulfur analysis provides accurate data within just a few minutes. This leap in testing speed enables rapid production decisions and significantly reduces the time spent waiting between powder receipt and production deployment. In practical terms, this enables us to reduce overall 3D printing service lead times by more than 20%, providing substantial time advantages for our customers.

Enhanced Quality Control and Reduced Batch Risk

High-speed testing capabilities allow us to implement more frequent sampling plans. For critical projects, we can even perform 100% batch testing to completely eliminate the risk of non-compliant powders entering production. This dense monitoring network ensures early detection and resolution of quality issues, effectively preventing batch failures. Statistical data indicate that since implementing this system, scrap rates resulting from material issues have decreased by 65%.

Meeting Stringent Traceability Requirements

Our carbon and sulfur analysis database is fully integrated with our production management system. Each test report is linked to specific powder batch numbers, production order numbers, and final part serial numbers. When customers request material quality data for a given lot, we can provide a complete report within 5 minutes. This high-efficiency traceability capability is especially valued by clients in the aerospace and medical device industries.

Synergy Between Carbon and Sulfur Analysis and Other Quality Control Technologies

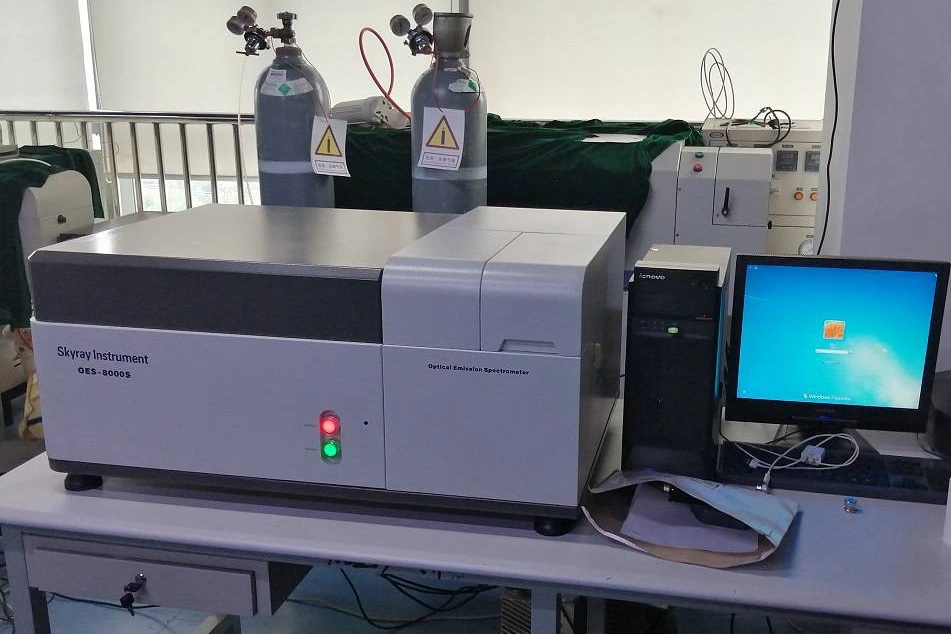

Complementarity with Direct-Reading Spectrometers

In our testing laboratory, the carbon and sulfur analyzer works in perfect synergy with the direct-reading spectrometer. Direct-reading spectrometers excel at measuring major alloying elements but have limited accuracy for non-metallic elements such as carbon and sulfur. The carbon and sulfur analyzer, dedicated to these two critical elements, provides precise quantification. Together, they form a complete chemical composition analysis solution, ensuring comprehensive monitoring of material chemistry.

Providing a Basis for Subsequent Performance Testing

Carbon and sulfur analysis data provide essential guidance for subsequent performance tests. When we detect abnormally high carbon content in a given batch, we pay special attention to its mechanical testing results, particularly strength and toughness. Likewise, materials with abnormal sulfur content undergo focused metallographic examination to check for sulfide inclusions. This data-driven targeted testing strategy significantly enhances both the efficiency and accuracy of quality control.

Application Case: How Carbon and Sulfur Analysis Intercepted a Non-Compliant Batch of Inconel 718 Powder

In the third quarter of last year, we received a batch of Inconel 718 powder that the supplier claimed fully met AMS 5662 requirements. Following our standard procedures, we immediately conducted analyses for carbon and sulfur content. The results showed sulfur content at 75 ppm—far exceeding the 50 ppm upper limit specified by the standard. We promptly activated our quality alert mechanism, quarantined the entire batch, and notified the supplier to conduct a joint investigation.

The investigation later revealed that a process failure during powder production had led to incomplete desulfurization. Had this powder been used in production, turbine blades manufactured from it would have suffered severe embrittlement under high-temperature service, potentially causing catastrophic failures. This incident not only prevented a major quality risk but also drove the supplier to improve its process control. The case clearly demonstrates the critical role of carbon and sulfur analysis within our quality control system.

Conclusion: Guarding Macroscopic Quality in the Microscopic World

As a key piece of material testing equipment, the carbon and sulfur analyzer plays an irreplaceable role in securing the quality of metal 3D printing. It acts like a “sentinel” within the quality system, safeguarding the macroscopic performance of final parts at the elemental level. At Neway, our continuous investment in advanced testing technologies reflects our firm commitment to ISO 9001-based quality assurance. We believe that only quality control grounded in scientific data can truly deliver products and services that our customers can trust.

Frequently Asked Questions

What are the typical detection range and accuracy of a carbon and sulfur analyzer?

How much sample is required for one carbon and sulfur analysis?

Besides metal powders, can finished printed parts also be tested for carbon and sulfur content?

Which international or industry standards do your carbon and sulfur analyses comply with?