Architectural Visualization Transformed With Ultra-Precise Resin 3D Printed Scale Models

Introduction

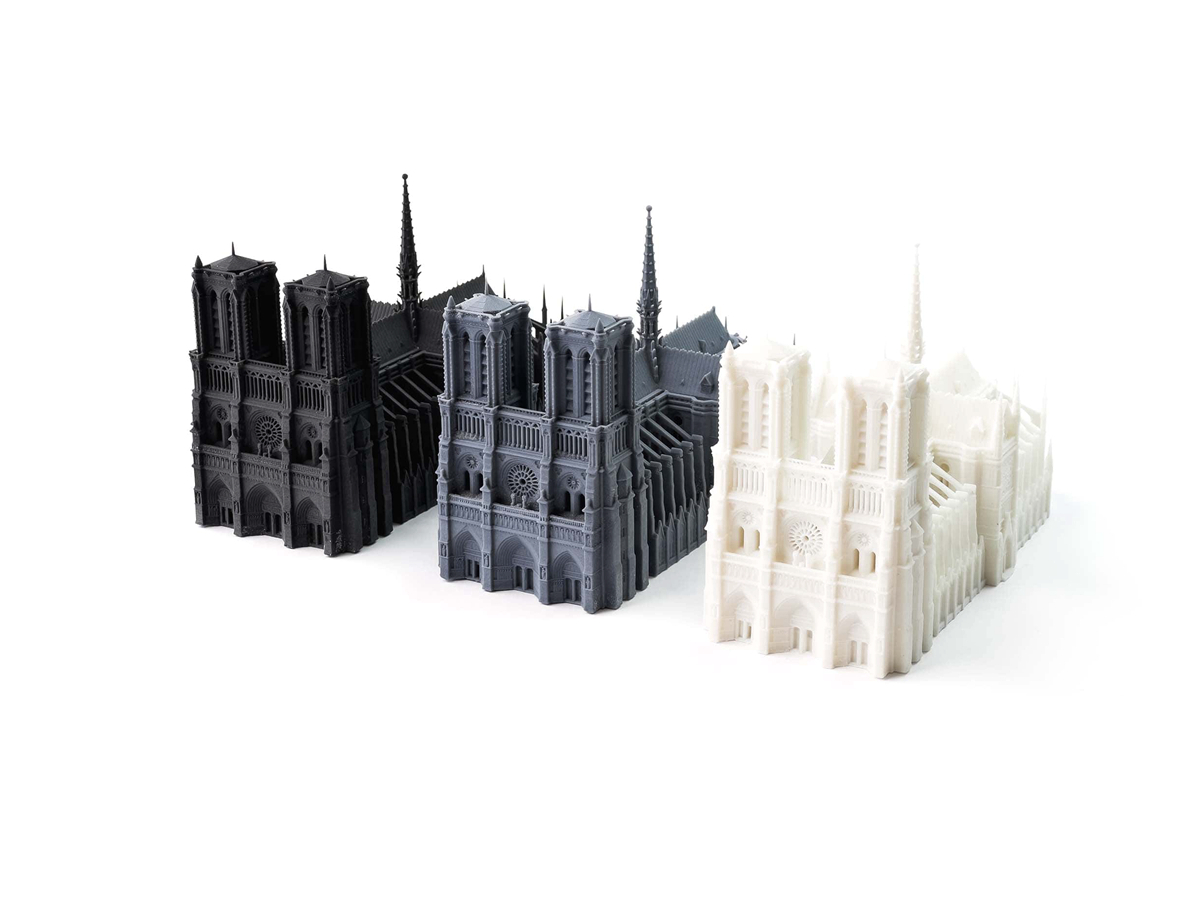

Ultra-precise resin 3D printing is revolutionizing architectural visualization by producing detailed, high-fidelity scale models that bring conceptual designs vividly to life. Utilizing advanced resin 3D printing technologies such as Stereolithography (SLA) and Digital Light Processing (DLP), premium resin materials like Standard Resin, Transparent Resin, and Durable Resin achieve unmatched surface finish, dimensional accuracy, and fine feature resolution essential for sophisticated architectural presentations.

Compared to traditional model-making methods, resin 3D printing for architectural models dramatically reduces production time, enhances complexity and realism, and supports faster design iterations for client engagement and project approval.

Applicable Material Matrix

Material | Surface Finish Quality | Dimensional Accuracy | Toughness | Feature Resolution | Architectural Model Suitability |

|---|---|---|---|---|---|

Excellent | ±0.03–0.05 mm | Moderate | Ultra-Fine | High-detail façade and massing models | |

Excellent | ±0.03–0.05 mm | Moderate | Fine | Windows, skylights, glass features | |

Good | ±0.05–0.08 mm | High | Fine | Repeat-use modular models | |

Very Good | ±0.05 mm | High | Fine | Functional assembly models |

Material Selection Guide

Standard Resin: Offers excellent surface smoothness and detail capture, ideal for architectural models emphasizing fine façades, urban layouts, and detailed interiors.

Transparent Resin: Best for integrating windows, skylights, and translucent elements into architectural scale models, enhancing realism.

Durable Resin: Suitable for modular or interactive models that require frequent handling and reconfiguration, such as building section displays or educational models.

Tough Resin: Provides mechanical resilience for prototypes or display models with moving parts like doors, elevators, and structural study elements.

Process Performance Matrix

Attribute | Resin 3D Printing Performance |

|---|---|

Dimensional Accuracy | ±0.03–0.05 mm |

Surface Roughness (As-Printed) | Ra 2–5 μm |

Layer Thickness | 25–100 μm |

Minimum Wall Thickness | 0.5 mm |

Feature Size Resolution | 100–300 μm |

Process Selection Guide

Ultra-Fine Detail Reproduction: SLA and DLP technologies reproduce intricate façade details, ornamental features, and thin architectural elements impossible with manual methods.

Seamless Transparency: Transparent resins create realistic glass effects for towers, residential developments, and interior structures, improving visual communication.

Rapid Model Updates: Design modifications can be quickly printed and integrated, helping architects adapt presentations to evolving client or regulatory requirements.

Scalable Modular Construction: Large projects can be broken into 3D printed modules for easy transport, reassembly, and updates during multi-phase developments.

Case In-Depth Analysis: SLA 3D Printed High-Rise Architectural Presentation Model

A top architecture firm required a detailed 1:500 scale model of a new urban high-rise development for investor presentations. Using our resin 3D printing service with Standard Resin for the main structure and Transparent Resin for window elements, we produced the model with layer thicknesses of 50 μm and dimensional accuracy within ±0.03 mm. Fine façade textures, balconies, and green rooftop elements were captured with exceptional clarity. Post-processing included sanding, priming, and hand-painting to achieve a polished, realistic presentation model that helped secure project funding.

Industry Applications

Architecture and Urban Design

Conceptual massing models for early-stage development.

Final presentation models for marketing and client approvals.

Modular site plans and urban planning visualizations.

Real Estate and Development Marketing

High-detail sales gallery models.

Interactive displays for residential, commercial, and mixed-use projects.

Education and Research

Architectural history study models.

Construction technique demonstrations for academic institutions.

Mainstream 3D Printing Technology Types for Architectural Models

Stereolithography (SLA): Best for ultra-smooth, highly detailed architectural models.

Digital Light Processing (DLP): Ideal for fast production of small-scale, intricate models.

Multi Jet Fusion (MJF): Suitable for durable, functional architectural prototypes with moderate detail.

FAQs

What resin materials are best for 3D printed architectural scale models?

How does resin 3D printing improve the precision and realism of architectural models?

Can transparent resin be used to simulate windows and glass features in building models?

What post-processing methods enhance the appearance of resin 3D printed architectural models?

How does 3D printing accelerate the creation and updating of architectural presentation models?