Can HIP improve the wear resistance of 3D printed components?

How Hot Isostatic Pressing (HIP) Improves Wear Resistance in 3D Printed Components

Enhanced Material Density and Microstructure

Hot Isostatic Pressing (HIP) significantly improves the wear resistance of 3D printed components by eliminating internal porosity and defects inherent to additive manufacturing processes like Selective Laser Melting (SLM) or Electron Beam Melting (EBM). During HIP, parts undergo simultaneous exposure to high temperatures (typically ranging from 900°C to 1200°C) and pressures around 100–200 MPa. This combination effectively reduces internal pores, resulting in near-theoretical densities (>99.9%) and a uniform, refined microstructure.

For instance, superalloy components such as Inconel 718 or Hastelloy X produced via Powder Bed Fusion processes exhibit substantial enhancements in hardness and abrasive resistance after HIP treatment. By minimizing internal voids and refining grain structures, the resultant component exhibits improved mechanical properties, particularly enhanced resistance to abrasive, erosive, and adhesive wear.

Improved Mechanical Properties and Hardness

Post-HIP treatment significantly elevates mechanical strength and hardness, directly influencing wear resistance. Materials like Tool Steel H13 and Stainless Steel SUS316L display notable improvements after HIP, with hardness increases commonly measured by Rockwell hardness scales (such as HRC), showing increases of 10–20% compared to untreated counterparts.

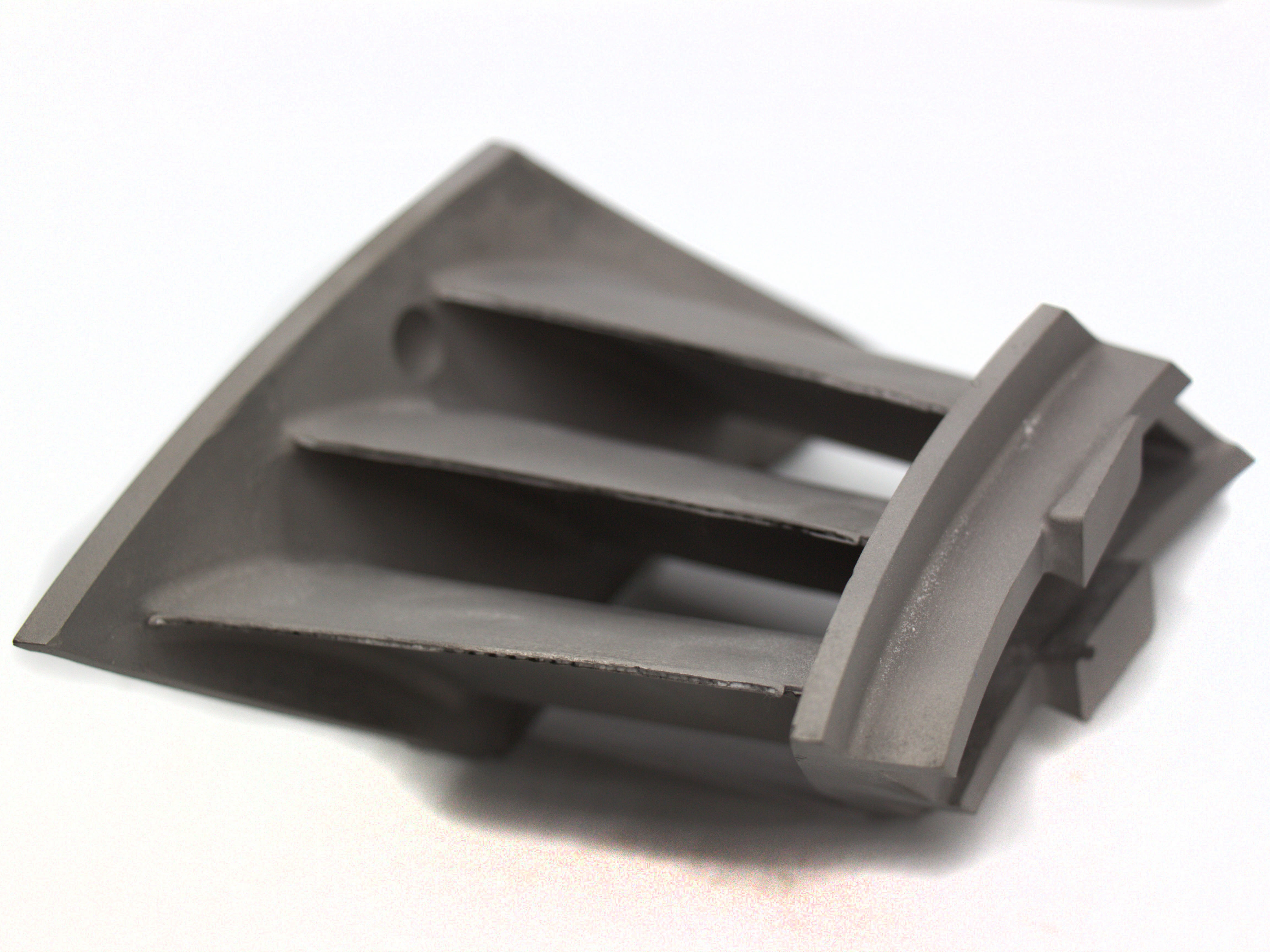

In practice, components used in demanding environments—such as automotive dies, medical implants, and aerospace turbine blades—demonstrate extended service life due to enhanced surface integrity and reduced susceptibility to micro-abrasion and fatigue wear after HIP processing.

Applicable Materials and Industries

HIP processing is particularly beneficial for components printed from high-performance materials, including:

Superalloys (e.g., Inconel 625, Hastelloy C-276)

Titanium alloys (e.g., Ti-6Al-4V, Ti-6Al-4V ELI)

Tool steels (e.g., Tool Steel D2, Tool Steel M2)

Stainless steels (e.g., SUS304, SUS17-4PH)

Industries such as aerospace, medical, and energy particularly benefit from HIP due to rigorous requirements for component durability and reliability.

Recommended Services for Enhanced Wear Resistance of Components

Customers aiming for enhanced wear resistance in their 3D printed components can leverage the following specialized services offered by Neway:

3D Printing Services for High-Performance Materials

Superalloy 3D Printing: Ideal for demanding high-temperature applications.

Titanium 3D Printing: Lightweight yet strong components suitable for aerospace and medical uses.

Stainless Steel 3D Printing: Durable components with excellent corrosion resistance.

Post-Processing for Mechanical Performance

Hot Isostatic Pressing (HIP): Reduces porosity and enhances material density and wear resistance.

CNC Machining: Provides precision finishing and dimensional accuracy after HIP treatment.

Advanced Surface Treatments

Nitriding: Significantly enhances surface hardness.

PVD Coating: Improves both wear resistance and surface finish.