What materials are best suited for EDM mirror finishing?

Best Materials for EDM Mirror Finishing

Superalloys and High-Temperature Alloys

Superalloys, including nickel-based alloys such as Inconel 718 and Hastelloy X, exhibit excellent machinability via Electrical Discharge Machining (EDM). Their high thermal resistance and strength properties make EDM an ideal solution to achieve mirror-like surface finishes with roughness as low as Ra 0.1–0.2 µm, critical in aerospace turbine blades and combustion components.

Titanium Alloys

Titanium alloys, notably Ti-6Al-4V (Grade 5) and medical-grade Ti-6Al-4V ELI (Grade 23), benefit significantly from EDM mirror finishing. Their biocompatibility combined with EDM's non-contact machining capability allows precise finishes without inducing mechanical stress, ideal for medical implants and aerospace structures.

Tool Steels

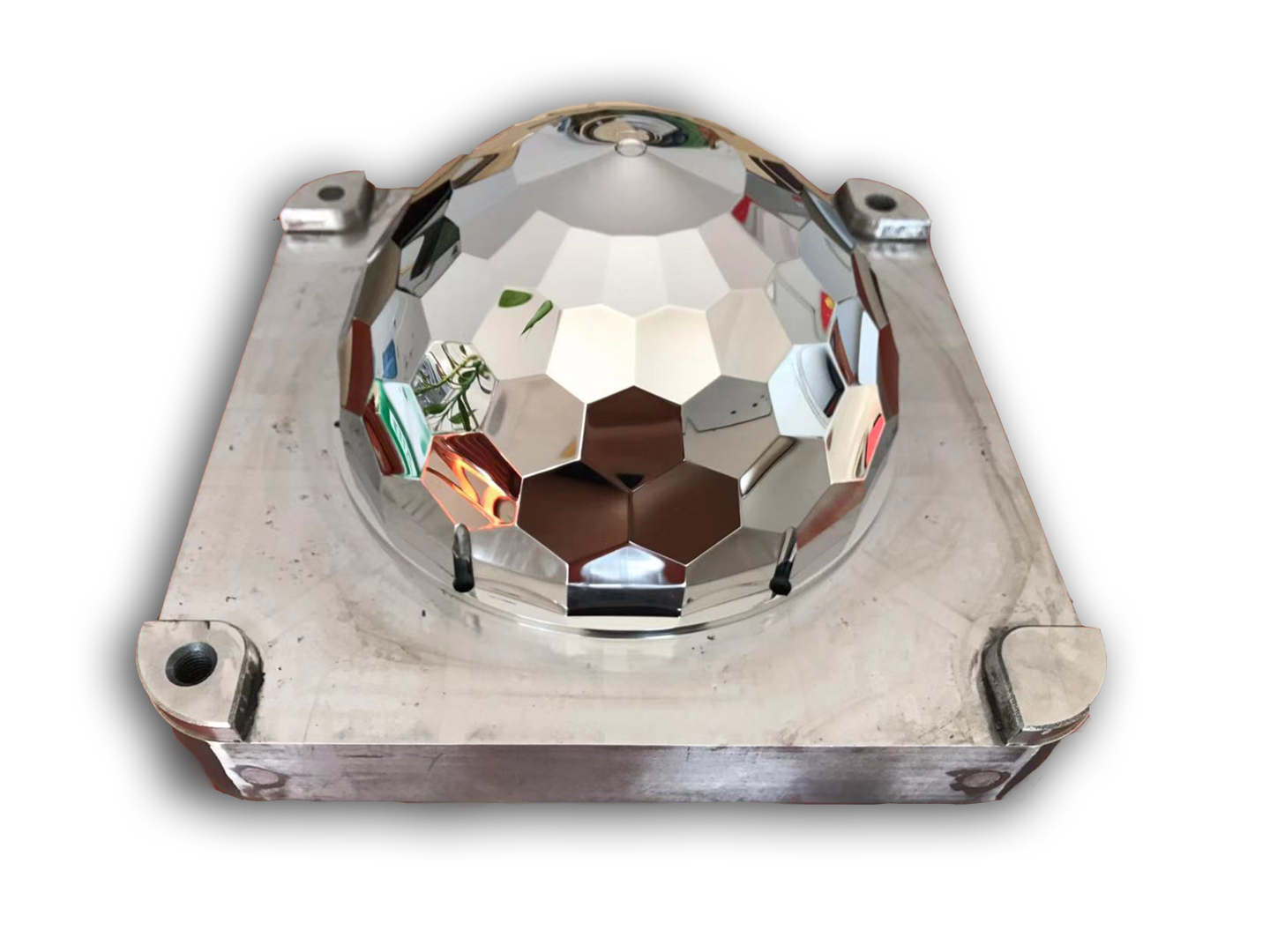

High-hardness tool steels such as Tool Steel H13, Tool Steel D2, and Tool Steel M2 are frequently chosen for EDM finishing. EDM efficiently processes these tough steels, achieving exceptionally smooth surfaces suitable for precision molds, dies, and tooling inserts, with achievable Ra values typically under 0.2 µm.

Stainless Steel

Austenitic and precipitation-hardening stainless steels such as SUS316L and SUS630/17-4 PH are ideal candidates for EDM finishing. These stainless steels offer excellent corrosion resistance, which complements EDM’s capability to deliver mirror finishes, essential in medical, automotive, and precision industrial applications.

Copper Alloys

Copper-based materials, especially Copper C101 and alloy CuCr1Zr, have high electrical conductivity and thermal stability, facilitating precise EDM processes. Such alloys typically achieve smooth surfaces (Ra < 0.2 µm) and are essential for electrode manufacturing, electrical contacts, and precision cooling components.

Recommended Additional Services for Enhanced Finishing

To further enhance EDM-processed components, customers frequently combine the following post-processing solutions:

Electropolishing Delivers additional corrosion protection and enhanced smoothness for high-purity medical and precision industrial components.

Heat Treatment Strengthens and stabilizes the structural integrity of finished EDM parts, improving hardness and fatigue resistance.

PVD Coating Provides robust surface enhancement with superior wear resistance and aesthetic appeal, beneficial in tooling and decorative applications.

Utilizing these complementary services from Neway 3DP ensures optimized performance and longevity of EDM-finished parts.