What is the most precise tolerance achievable with EDM machining?

Most Precise Tolerance Achievable with EDM Machining

EDM Tolerance Capabilities

Electrical Discharge Machining (EDM) is renowned for its high-precision capability, particularly for complex geometries and hard-to-machine materials. At Neway 3DP, our EDM processes routinely achieve tolerances of ±0.005 mm, and under optimized conditions, down to ±0.002 mm for fine-featured components. These tolerances are maintained consistently due to the non-contact nature of EDM, which eliminates cutting force-induced deflection.

Influencing Factors for Maximum Precision

Material Properties

Stable, conductive materials with uniform grain structures—such as Tool Steel 1.2709, Ti-6Al-4V, and Inconel 625—support tighter tolerances during EDM. These materials resist thermal distortion and maintain dimensional stability during discharge cycles.

Electrode Design and Wear

Using high-conductivity electrodes such as Copper C110 or CuCr1Zr ensures minimal tool wear and high repeatability in micro-scale features. Precision-machined electrodes also enable tighter gap control and enhanced edge definition.

Dielectric Fluid Control

Precise temperature and contamination control of dielectric fluid maintains spark stability, essential for micron-level machining. Advanced flushing systems support dimensional accuracy even in deep cavity or high-aspect-ratio geometries.

EDM Machine Resolution

Neway’s EDM equipment includes CNC-controlled machines capable of sub-micron axis movement (±1 µm positioning resolution), supported by stable thermal compensation systems to maintain accuracy in varying conditions.

Typical Applications Requiring Ultra-Tight EDM Tolerances

Medical stents and implants with fine geometries in Ti-6Al-4V ELI (Grade 23)

Aerospace injectors, micro-nozzles, and turbine cooling features in Hastelloy C-276

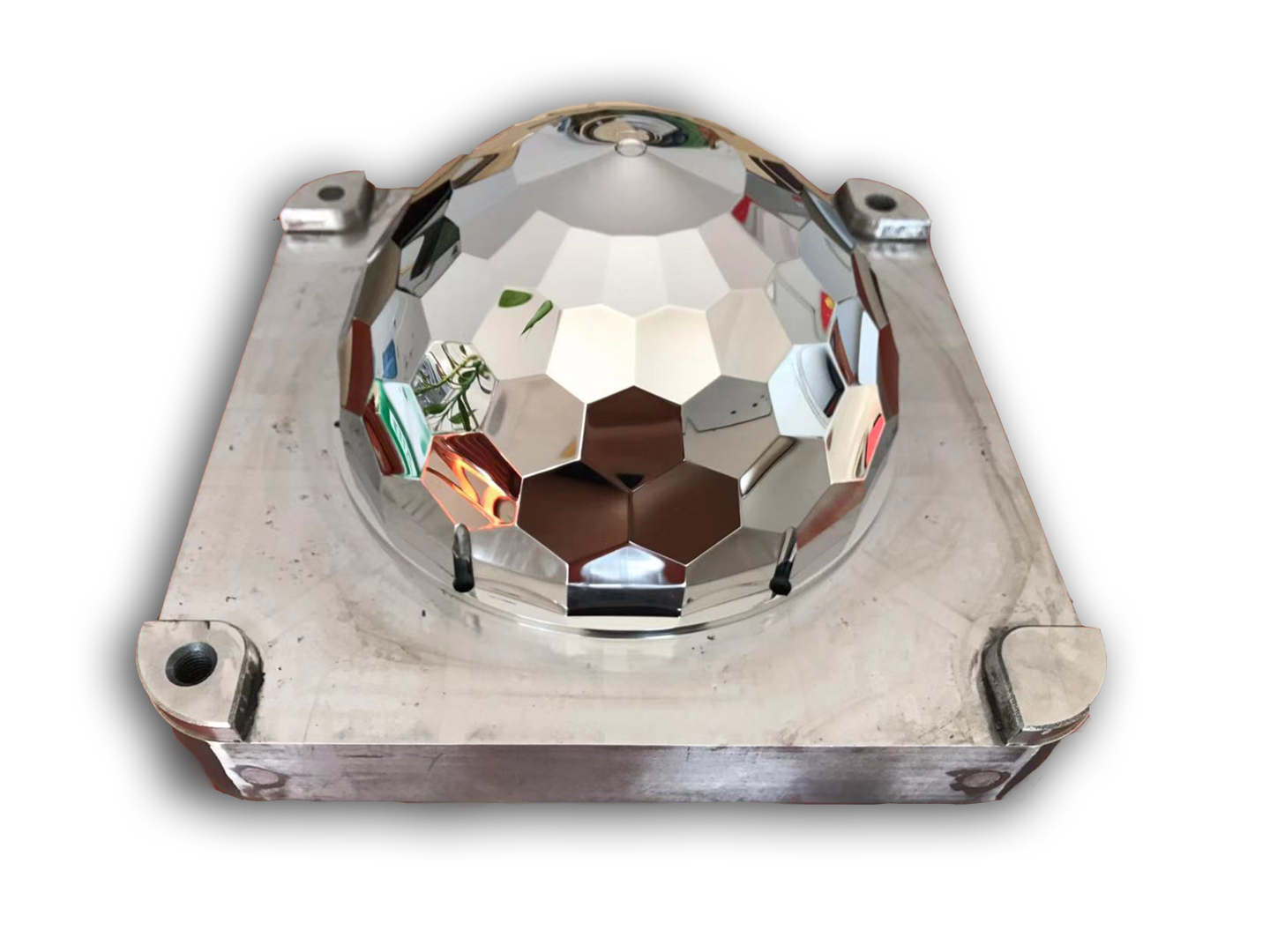

High-performance mold cores, dies, and precision tooling inserts in Tool Steel H13

Post-Processing Services to Complement High-Precision EDM

To maintain and enhance micron-level EDM tolerances, we recommend:

CNC Machining For secondary dimensional refinement or hybrid machining workflows.

Heat Treatment To stabilize mechanical properties and ensure long-term dimensional accuracy.

Polishing For final surface preparation without compromising precision.

Our integrated approach ensures EDM parts meet stringent aerospace, medical, and tooling requirements.