What are the typical applications for high-precision EDM machining?

Typical Applications for High-Precision EDM Machining

Aerospace Industry Applications

Turbine Components and Cooling Channels

EDM enables the machining of complex features such as cooling holes, venting grooves, and sharp-edged contours in turbine blades and vanes made from Inconel 718, Hastelloy X, and Haynes 230. With tolerances down to ±0.002 mm, EDM ensures aerodynamic precision and thermal stability under extreme operating conditions.

Lightweight Titanium Structures

Titanium parts like brackets, fasteners, and internal components fabricated from Ti-6Al-4V (Grade 5) benefit from EDM's non-contact process. This ensures distortion-free finishes for high-performance, weight-critical aerospace applications.

Medical Device Applications

Surgical Instruments and Implants

EDM is ideal for producing sharp, precise edges and fine features in surgical tools and implants made from Ti-6Al-4V ELI (Grade 23) and SUS316L. It enables fine detailing in orthopedic screws, dental drills, and bone-cutting tools, where sub-0.005 mm tolerances and Ra < 0.2 µm finishes are required.

Microfluidic Channels

Precision EDM is used in diagnostic and surgical fluid systems to create clean, burr-free microchannels in hard-to-machine alloys, maintaining smooth flow and minimizing contamination risk.

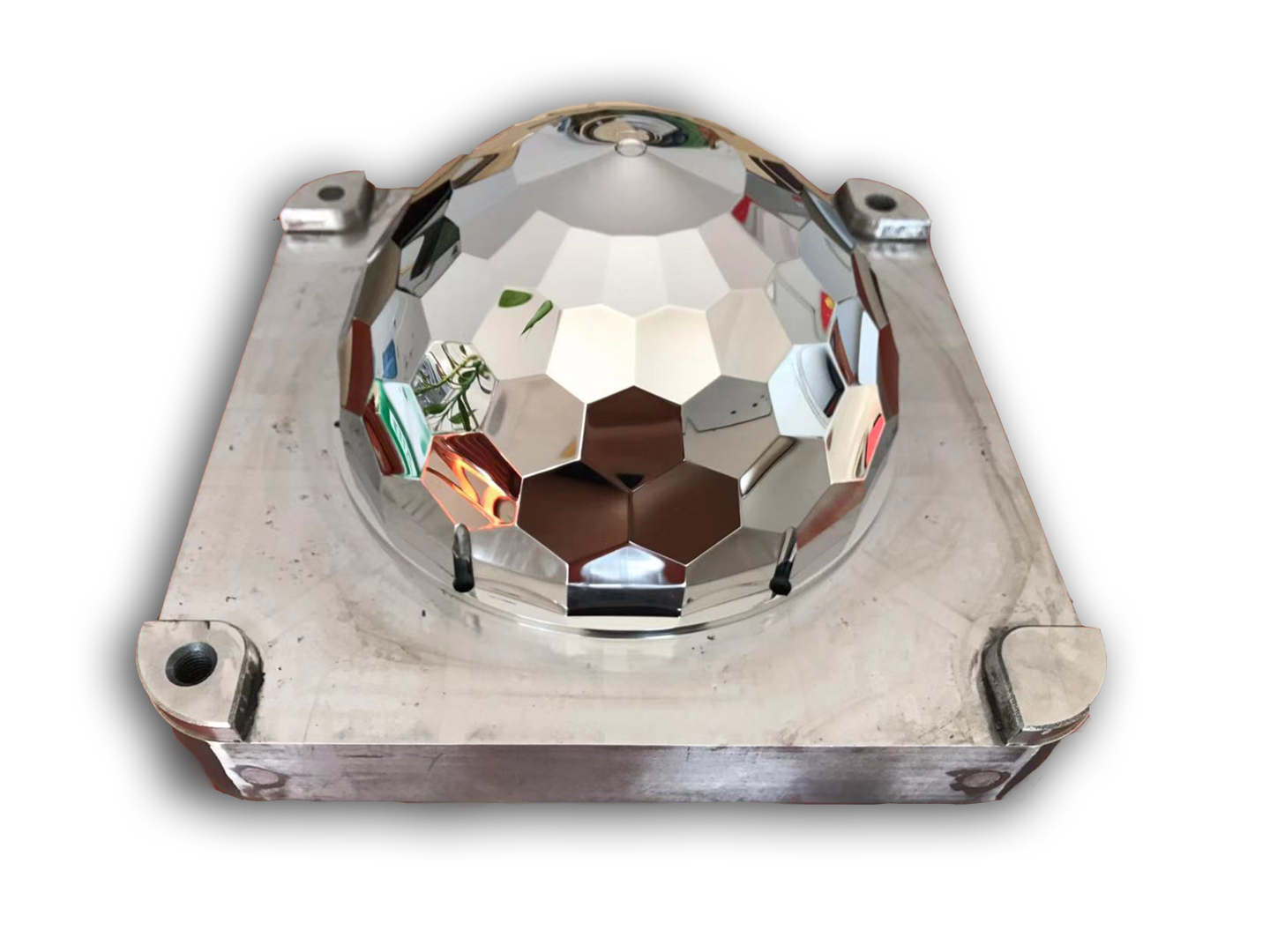

Mold and Die Making

Precision Tool Inserts

EDM is a standard for producing hardened tool steels such as Tool Steel H13, Tool Steel D2, and Tool Steel 1.2709. It allows the creation of complex cavities, tight radii, and mirror-finished surfaces for injection molds, stamping dies, and extrusion tooling.

Micro-EDM Applications

For micro-tooling, EDM is used to fabricate tiny features like ejector pin holes, narrow slots, and tiny ribs with extreme repeatability, unattainable by conventional machining.

Electronics and Optoelectronics

High-Fidelity Electrode Fabrication

EDM produces intricate electrodes from Copper C110 and CuCr1Zr used in semiconductor molds, high-voltage connectors, and cavity molds with optical-grade surfaces.

Recommended Services for High-Precision Applications

Neway 3DP supports critical sectors with the following services:

EDM Machining Achieve tight-tolerance, fine-featured machining in heat-resistant and medical-grade materials.

Heat Treatment Strengthen structural integrity and dimensional stability for aerospace and tool steel components.

Electropolishing Enhance biocompatibility and corrosion resistance for surgical and implant-grade parts.

Our capabilities ensure consistent accuracy and compliance with industry standards in medical, aerospace, and tooling applications.