How does EDM achieve a mirror finish on 3D printed parts?

How EDM Achieves a Mirror Finish on 3D Printed Parts

Understanding the EDM Process

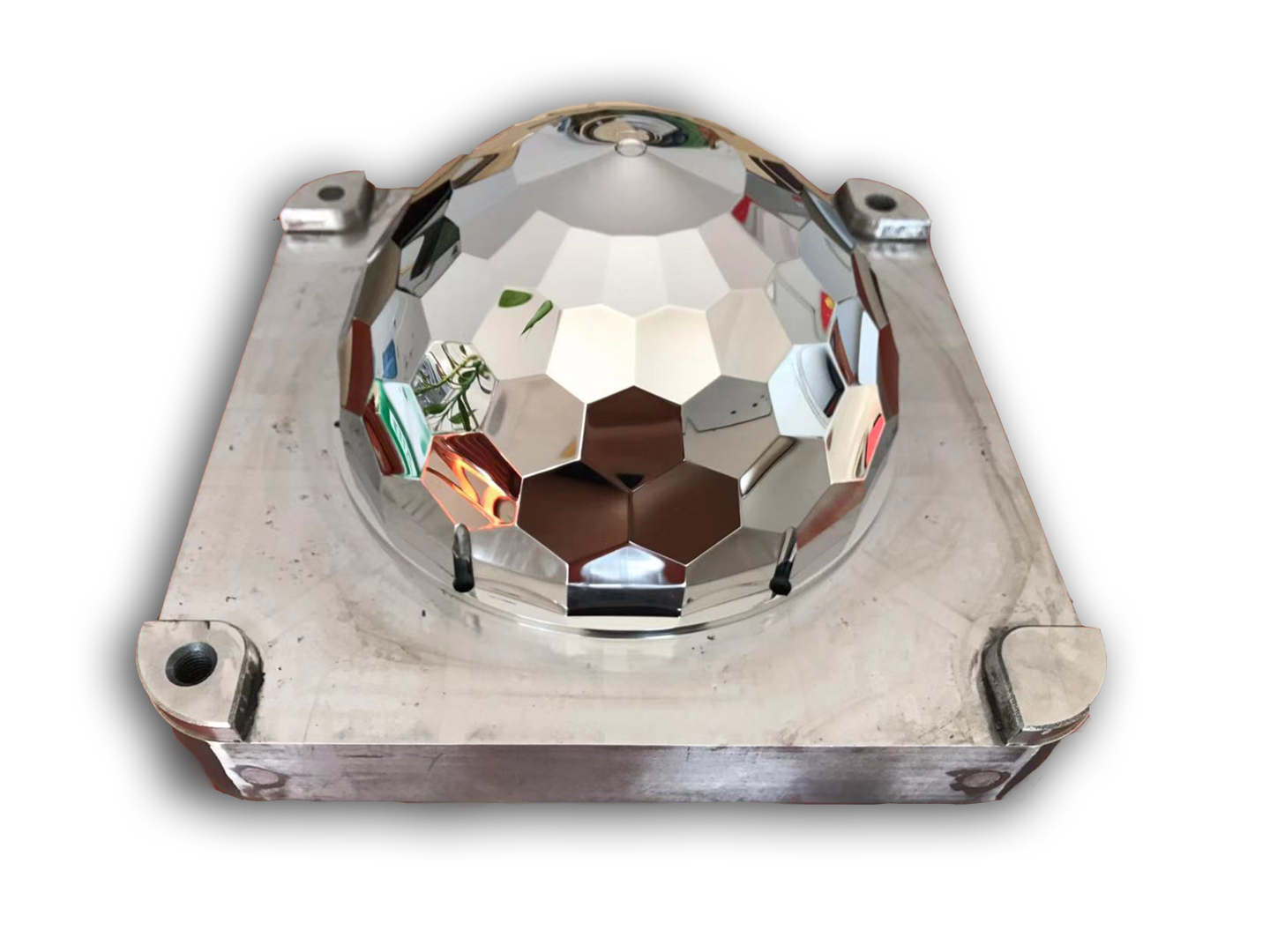

Electrical Discharge Machining (EDM) is an advanced post-processing technique that employs precisely controlled electrical discharges between an electrode and a 3D printed metal part submerged in dielectric fluid. By meticulously controlling discharge parameters—such as voltage, current, and pulse frequency—EDM effectively removes surface imperfections and achieves exceptionally smooth, mirror-like finishes. EDM is particularly suitable for metal components manufactured via additive methods like Selective Laser Melting (SLM) and Electron Beam Melting (EBM).

Key Factors Influencing Mirror Finish Quality

Electrode Material and Precision

Electrode materials significantly impact the achievable surface quality. Highly conductive copper-based alloys like Copper C101 or CuCr1Zr electrodes enable stable electrical discharges and fine finishes. Precisely machined electrodes help ensure uniform erosion, delivering Ra surface roughness values typically less than 0.2 µm.

EDM Parameter Control

Achieving a mirror finish demands optimal EDM parameters. Typically, low energy pulses (<1 joule), short pulse durations (1–10 µs), and tightly maintained gap distances (5–25 microns) are necessary. Precise control over these parameters significantly reduces surface roughness and minimizes thermal damage or micro-cracks.

Dielectric Fluid Quality

High-quality dielectric fluids, such as deionized water or specialized EDM oils, provide consistent insulation and effective flushing of debris. Proper dielectric fluid selection maintains discharge precision, minimizes surface irregularities, and enhances final part quality.

Advantages of EDM for Mirror Finishing 3D Printed Components

EDM is particularly effective for mirror-polishing additive-manufactured components crafted from high-performance metals, including Inconel 718, Ti-6Al-4V Grade 5, or tool steels such as Tool Steel H13. Its capability to finish complex geometries, intricate cavities, and internal channels surpasses conventional mechanical methods, ensuring exceptional precision and aesthetic appeal.

Typical Applications of EDM Mirror Finishes

Medical implants using biocompatible alloys like Ti-6Al-4V ELI (Grade 23)

Aerospace turbine blades fabricated from superalloys such as Hastelloy X or Haynes 230

High-precision tooling inserts and dies produced from hardenable steels like Tool Steel D2 or Tool Steel M2

Recommended Post-processing and Surface Treatment Services

To maximize the benefits of EDM mirror finishes, Neway 3DP offers customers additional value-added services:

CNC Machining Precision CNC machining ensures dimensional accuracy and optimal geometric details, complementing EDM finishes.

Electropolishing Offers superior corrosion resistance and enhances surface smoothness, particularly valuable for medical and aerospace components.

PVD Coating Provides protective, wear-resistant coatings that enhance durability and visual appeal, ideal for finished EDM components.

By combining EDM with these advanced processes, customers can achieve high-performance, aesthetically superior components tailored for demanding applications.