Spinel (Magnesium Aluminate)

Spinel 3D Printing Materials Introduction

Spinel (MgAl₂O₄) is a transparent polycrystalline ceramic combining high hardness, thermal shock resistance, and broad-spectrum optical transmission. Its superior mechanical properties and infrared transparency make it ideal for defense, aerospace, and optical applications.

Through ceramic 3D printing, spinel enables the rapid production of complex components such as protective windows, domes, and optical lenses with unmatched durability and precision.

Spinel Similar Grades Table

Country/Region | Standard | Grade or Designation |

|---|---|---|

USA | MIL | MIL-PRF-32295 |

ISO | International | ISO 14704 |

China | GB | GB/T 24096 |

Germany | DIN | DIN 51084 |

Japan | JIS | JIS R1611 |

Spinel Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 3.58 g/cm³ |

Optical Transmission Range | 0.2–5.5 µm | |

Refractive Index (1 µm) | ~1.72 | |

Thermal Conductivity (25°C) | 14.0 W/(m·K) | |

Thermal Expansion (20–1000°C) | 7.45 µm/(m·K) | |

Chemical Composition | MgO | 28–30% |

Al₂O₃ | 70–72% | |

Impurities | <0.1% | |

Mechanical Properties | Flexural Strength | 300–400 MPa |

Fracture Toughness (K₁C) | 2.0–2.8 MPa·m½ | |

Hardness | 1400 HV | |

Young’s Modulus | 275 GPa |

3D Printing Technology of Spinel

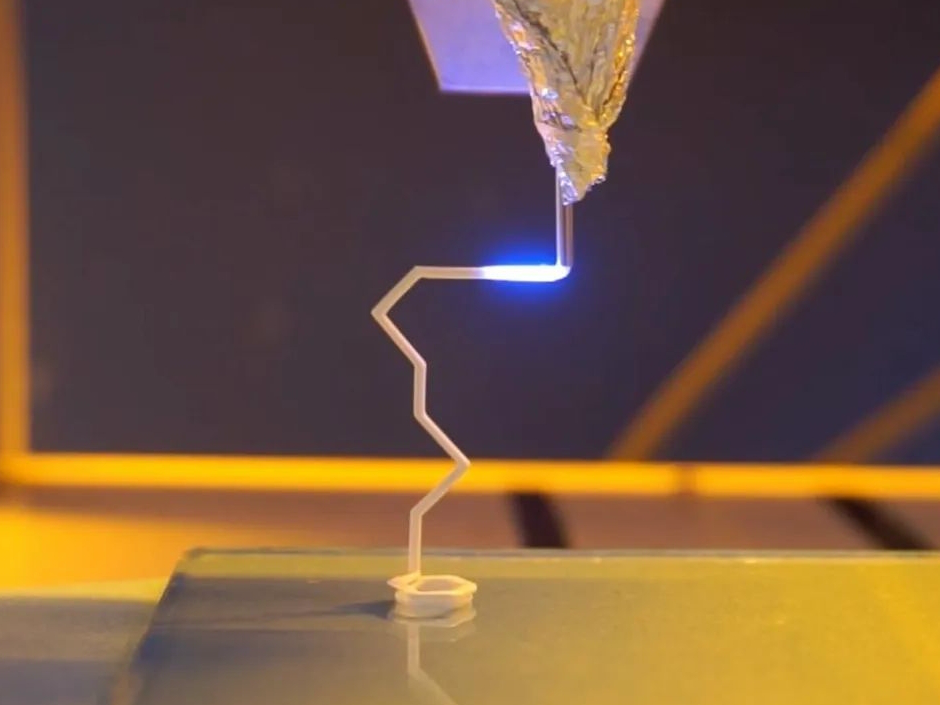

Spinel is compatible with advanced Vat Photopolymerization (SLA, DLP), Binder Jetting, and Material Extrusion processes. These methods enable the formation of complex geometries and thin-walled parts while maintaining high structural integrity after sintering.

Applicable Process Table

Technology | Precision | Density Achievable | Application Suitability |

|---|---|---|---|

DLP/SLA | ±0.05–0.1 mm | >98% | Optical lenses, transparent armor |

Binder Jetting | ±0.1–0.3 mm | 95–97% | Domes, windows, infrared optics |

Robocasting | ±0.1–0.2 mm | 92–95% | Structural optical components |

Spinel 3D Printing Process Selection Principles

For high-clarity optical parts such as lenses and domes, DLP/SLA is preferred for its fine resolution (±0.05 mm) and excellent surface quality after sintering.

Binder Jetting is suited for thicker components and larger optics requiring near-net-shape formation with moderate post-processing.

Material Extrusion is ideal for structural optical supports and housings where transparency is less critical but mechanical stability is required.

Spinel 3D Printing Key Challenges and Solutions

Spinel requires high-temperature sintering (~1600°C), which can cause warping and grain boundary defects. Controlled heating profiles and nano-powders minimize shrinkage mismatch and internal stress.

Achieving high optical clarity is challenging due to porosity and light scattering. Using fine powders, vacuum sintering, and pressure-assisted sintering techniques significantly enhance transmission.

Binder burnout must be carefully managed to prevent internal cracks. Stepwise debinding under air and vacuum ensures structural integrity before densification.

Surface finish directly affects transparency. Diamond grinding and mechanical polishing reduce surface roughness below 10 nm Ra, essential for optical performance.

Typical Post-Processing for Spinel 3D Printed Parts

Sintering at 1550–1650°C is required to achieve full densification and optical clarity in spinel ceramic components. Polishing is essential to minimize surface roughness for transparent optical windows and infrared domes. Electropolishing can refine internal passages in structural parts without compromising shape accuracy. Coating with anti-reflective or protective films extends service life in harsh thermal and optical environments.

Industry Application Scenarios and Cases

Spinel’s hardness, thermal resistance, and transparency make it ideal for:

Aerospace and Defense: Transparent armor, sensor windows, and infrared domes for missiles and UAVs.

Optics and Photonics: Lenses, prisms, and substrates for broadband infrared imaging and high-power laser systems.

Industrial and Scientific: Protective covers, optical probes, and chemically resistant viewports.

One defense application involved DLP 3D printed spinel windows for missile seekers, achieving >80% transmission in 3–5 µm IR range and impact resistance exceeding MIL-PRF-32295 specifications.

FAQs

What makes spinel superior to glass or sapphire in 3D printed optics?

Which 3D printing technology is most suitable for transparent spinel parts?

How is surface clarity achieved in 3D printed spinel ceramics?

What are the primary industries using magnesium aluminate spinel components?

What post-processing steps are required to ensure spinel's optical performance?