Magnesium oxide (MgO)

Magnesium Oxide (MgO) is a refractory ceramic offering excellent thermal conductivity, dielectric strength, and high-temperature stability up to 2800°C. It is widely used in industrial furnaces, crucibles, and electrical insulation applications.

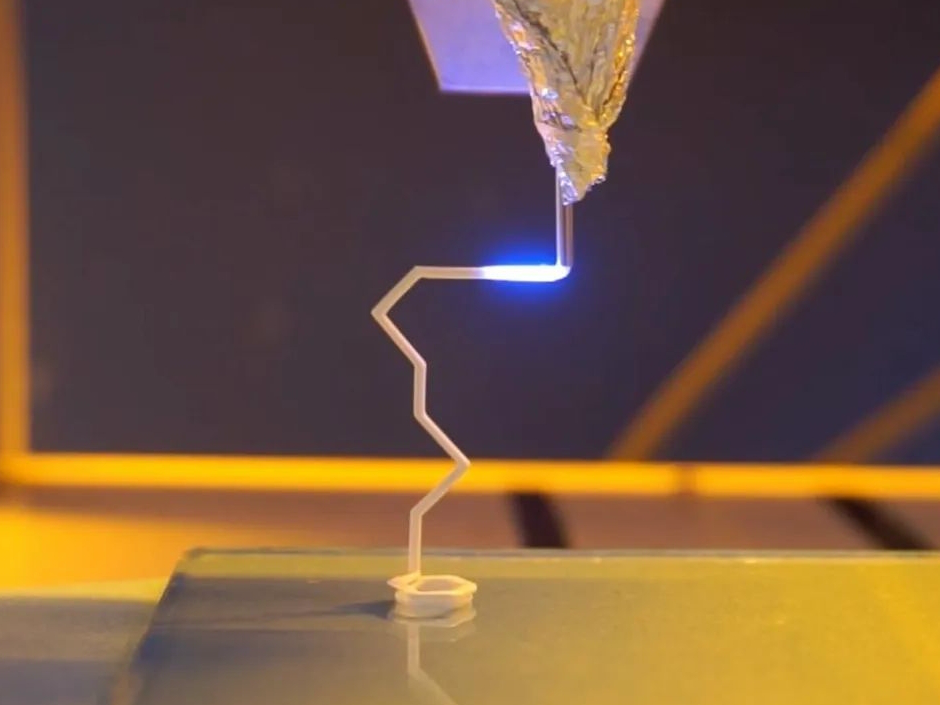

Using ceramic 3D printing, MgO parts can be manufactured into intricate shapes such as heating element supports, thermocouple sleeves, and arc-resistant components. Additive manufacturing reduces tooling costs and allows on-demand production of complex refractory structures.

Magnesium Oxide Similar Grades Table

Grade Type | Purity (%) | Typical Applications |

|---|---|---|

Technical Grade MgO | 90–96 | Furnace linings, foundry tools |

High-Purity MgO | ≥99.0 | Thermocouple tubes, electrical insulators |

Electro-Fused MgO | ≥99.5 | Plasma crucibles, induction coils |

Magnesium Oxide Comprehensive Properties Table

Category | Property | Value |

|---|---|---|

Physical Properties | Density | 3.58 g/cm³ |

Melting Point | ~2800°C | |

Thermal Conductivity (25°C) | 40–60 W/(m·K) | |

Electrical Resistivity (25°C) | >10¹⁴ Ω·cm | |

Thermal Expansion (20–1000°C) | 10.5 µm/(m·K) | |

Mechanical Properties | Hardness (Mohs) | ~5.5 |

Flexural Strength | 70–120 MPa | |

Compressive Strength | ≥300 MPa | |

Elastic Modulus | 100–130 GPa | |

Fracture Toughness (K₁C) | ~1.5 MPa·m½ |

3D Printing Technology of Magnesium Oxide

MgO is commonly printed using Binder Jetting and Vat Photopolymerization (VPP), followed by debinding and high-temperature sintering. These technologies enable customized production of thermally robust and electrically insulating ceramic parts.

Applicable Process Table

Technology | Precision | Surface Quality | Mechanical Properties | Application Suitability |

|---|---|---|---|---|

Vat Photopolymerization (VPP) | ±0.05–0.2 mm | Excellent | Good | Electrical Insulators, Sleeves |

Binder Jetting | ±0.1–0.3 mm | Good | Moderate | Furnace Parts, High-Temp Fixtures |

Magnesium Oxide 3D Printing Process Selection Principles

VPP is ideal for high-precision MgO components like sensor housings and electrical bushings requiring tight tolerances (±0.05–0.2 mm) and smooth internal geometries.

Binder Jetting is suited for larger, high-temperature components such as crucibles and refractory linings, balancing cost efficiency with adequate resolution.

Magnesium Oxide 3D Printing Key Challenges and Solutions

MgO is highly hygroscopic, absorbing moisture easily. Controlled storage (RH < 30%) and drying protocols are essential to prevent cracking during debinding and sintering.

Shrinkage during sintering (~20–25%) must be pre-compensated in CAD modeling. Custom sintering schedules improve dimensional stability and microstructural density.

Porosity and surface roughness can limit dielectric performance. Applying high solids-loading slurries and post-sinter polishing can achieve Ra < 1.5 µm, enhancing both insulation and structural properties.

Proper temperature ramp rates (e.g., ≤3°C/min) reduce cracking risk in complex shapes during high-temperature firing.

Industry Application Scenarios and Cases

Magnesium oxide is used in:

Electrical Insulation: High-voltage feedthroughs, arc-resistant bushings, and heating element sleeves.

Refractory Applications: Kiln components, induction furnace linings, and crucibles.

Sensors and Thermal Control: Thermocouple protection tubes and radiant heat reflectors.

In a recent furnace application, binder jet 3D printed MgO crucibles with internal baffles replaced machined parts, cutting production time by 50% and withstanding repeated cycles above 1800°C with zero failure.

FAQs

What are the key advantages of using MgO for 3D printed furnace components?

How does MgO compare with Alumina and Zirconia in thermal performance?

What are the handling precautions for 3D printing magnesium oxide?

Which applications benefit most from MgO’s electrical insulation properties?

What post-processing is required to improve MgO surface quality and density?