AISI 4140

Introduction to AISI 4140 for 3D Printing

AISI 4140 is a low-alloy steel containing approximately 0.38-0.43% carbon, 0.75-1.00% manganese, 0.80-1.10% chromium, and 0.15-0.25% molybdenum, offering high tensile strength up to 1,030 MPa and excellent toughness. Widely adopted in automotive, aerospace, and tooling industries, it is suitable for critical components subject to high stress and dynamic loads.

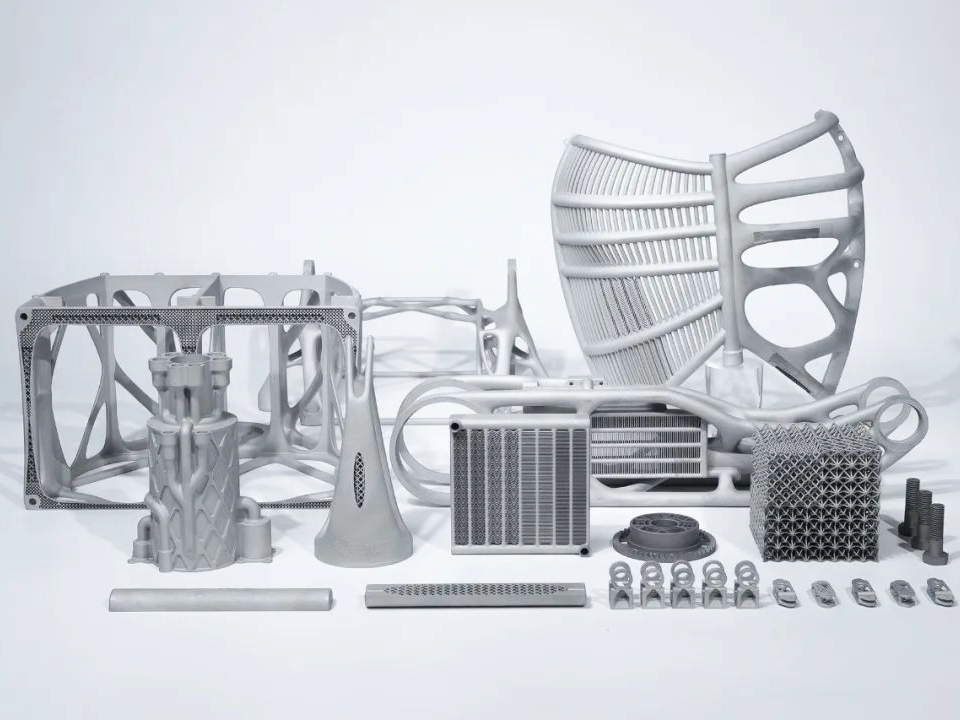

Utilizing processes like Direct Metal Laser Sintering (DMLS) and Wire Arc Additive Manufacturing (WAAM), AISI 4140 delivers precise geometries and dimensional accuracies within ±0.1 mm, fulfilling strict mechanical and functional standards required by professional applications.

International Equivalent Grades of AISI 4140

Country | Grade Number | Other Names/Titles |

|---|---|---|

USA | AISI 4140 | SAE 4140, UNS G41400 |

China | 42CrMo | GB/T 3077 |

Germany | 1.7225 | 42CrMo4, DIN 42CrMo4 |

Japan | SCM440 | JIS G4105 |

UK | 708M40 | BS970-1955 |

Comprehensive Properties of AISI 4140

Property Category | Property | Value |

|---|---|---|

Physical | Density | 7.85 g/cm³ |

Melting Point | 1,425°C | |

Thermal Conductivity | 42.6 W/m·K | |

Coefficient of Thermal Expansion (CTE) | 12.3 µm/m·°C | |

Chemical | Carbon (C) | 0.38-0.43% |

Manganese (Mn) | 0.75-1.00% | |

Chromium (Cr) | 0.80-1.10% | |

Molybdenum (Mo) | 0.15-0.25% | |

Iron (Fe) | Balance | |

Mechanical | Tensile Strength | 1,030 MPa |

Yield Strength | 655 MPa | |

Elongation | 17% | |

Hardness (Rockwell C) | 28-32 HRC |

Suitable 3D Printing Processes for AISI 4140

Process | Typical Density Achieved | Surface Roughness (Ra) | Dimensional Accuracy | Application Highlights |

|---|---|---|---|---|

≥99% | 8-12 µm | ±0.1 mm | Ideal for complex shapes, tooling inserts, and functional prototypes demanding high strength | |

≥99.5% | 25-40 µm | ±0.5 mm | Efficient for large-scale parts like automotive components, industrial tooling, and structural elements |

Selection Criteria for AISI 4140 3D Printing Processes

Part Complexity: DMLS is optimal for intricate designs requiring precision up to ±0.1 mm, suited to high-strength tooling and aerospace parts.

Mechanical Strength Requirements: DMLS and WAAM offer tensile strengths of approximately 1,030 MPa, ideal for demanding applications involving dynamic stress and heavy loads.

Build Volume Requirements: WAAM supports large parts efficiently with deposition rates exceeding 150 cm³/h; DMLS caters to small-to-medium, detailed components.

Post-Processing Necessities: Additional heat treatments and machining enhance mechanical properties, toughness, and dimensional stability for high-stress applications.

Essential Post-Processing Methods for AISI 4140 3D Printed Parts

Heat Treatment: Tempering performed at ~550°C increases tensile strength up to 1,200 MPa and significantly enhances toughness.

CNC Machining: Precision machining ensures dimensional tolerances of ±0.02 mm, creating precise mating surfaces for mechanical components.

Electroplating: Electrochemical deposition adds corrosion resistance and reduces surface roughness below 1 µm Ra, enhancing functional performance.

Shot Peening: Performed with high-velocity abrasive media, improves fatigue strength by up to 20% and surface hardness significantly.

Challenges and Solutions in AISI 4140 3D Printing

Internal Stress and Warping: Controlled build chamber temperatures (~200°C) combined with stress-relief heat treatments mitigate internal stresses, preventing part deformation.

Porosity and Density Issues: Optimizing laser power (180-200W) and scanning speed ensures consistent melting, achieving densities above 99%.

Surface Quality Control: Careful parameter tuning and employing finishing processes like CNC machining achieve required surface roughness (<5 µm Ra) for functional applications.

Applications and Industry Case Studies

AISI 4140 is extensively applied in:

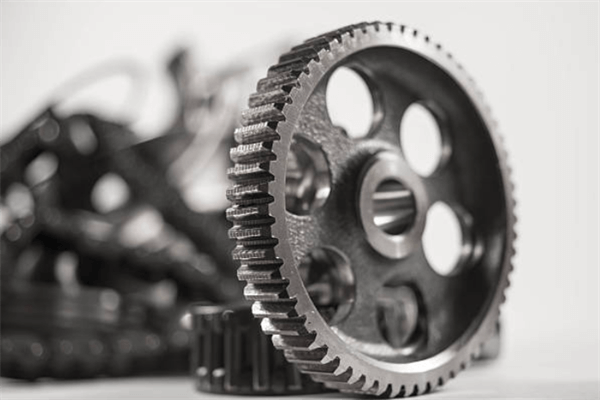

Automotive: High-strength drivetrain components, gears, shafts, and structural chassis parts.

Aerospace: Landing gear components, engine mounts, and structural brackets.

Tooling and Manufacturing: Injection molds, die-casting dies, punches, and tool holders.

Energy and Oil & Gas: Drill collars, pump components, and critical structural elements.

Case Study: Automotive drivetrain gears fabricated using DMLS with subsequent CNC machining and heat treatments showed improved mechanical integrity and wear resistance.

Frequently Asked Questions (FAQs)

What are the mechanical advantages of using AISI 4140 for 3D printed components?

Which 3D printing processes deliver the best performance for AISI 4140 parts?

How can post-processing improve the toughness and wear resistance of AISI 4140 components?

What size limitations exist for 3D printing large-scale AISI 4140 parts?

How does AISI 4140 compare with other alloy steels used in additive manufacturing?