Electroplating Explained: How It Improves Durability and Corrosion Resistance

Introduction

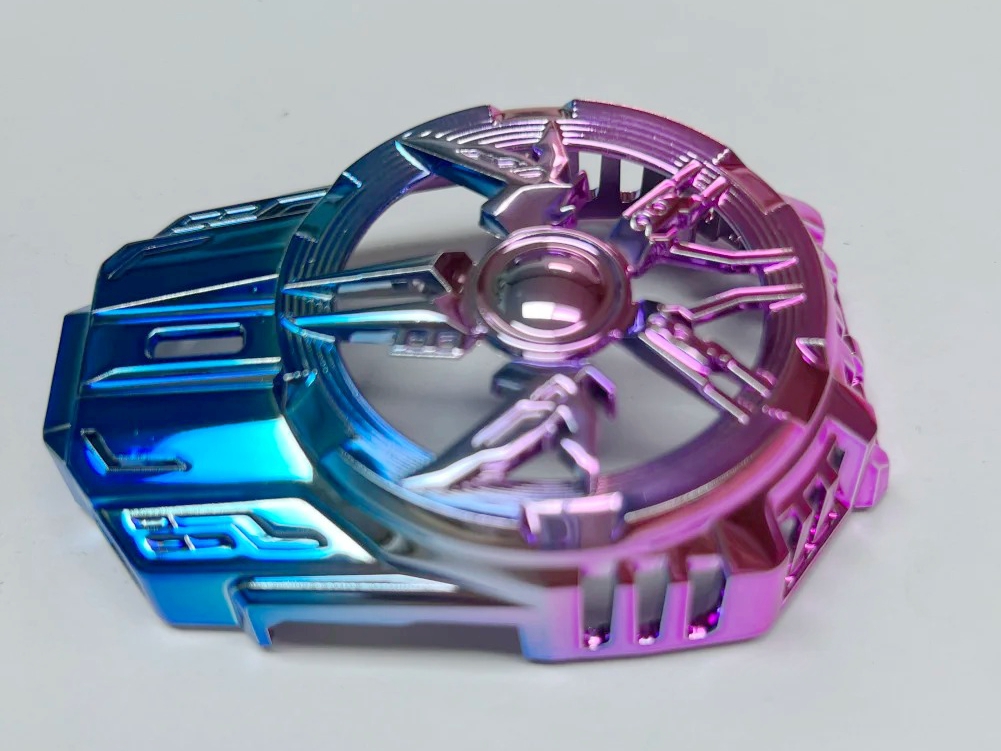

Electroplating is a widely used surface treatment process that significantly improves the durability, hardness, and corrosion resistance of 3D printed parts. This electrochemical technique involves depositing a thin layer of metal onto the surface of 3D printed components, enhancing their performance in harsh environments. Electroplating not only increases the part’s lifespan but also provides an attractive, metallic finish highly valued in aerospace, automotive, and electronics industries.

In this blog, we will explain how electroplating works, its key benefits, and its application in improving 3D printed parts for industries that require strength, corrosion resistance, and high-quality finishes. We will also compare electroplating with other surface treatment methods and explore the materials best suited for this technique.

How Electroplating Works and Quality Assessment Criteria

Electroplating is an electrochemical process in which metal ions are reduced and deposited onto the surface of a 3D printed part from a metal salt solution. The process involves immersing the part in an electrolyte bath containing metal salts, where an electrical current is passed through the solution to deposit the metal onto the part’s surface. The thickness of the electroplated layer can vary from a few microns to several hundred microns, depending on the application.

The quality of electroplated coatings is assessed through several criteria:

Coating Thickness: Electroplated coatings typically range from 5 to 50 microns, though thicker coatings may be applied depending on the material and application requirements.

Adhesion Strength: Electroplating provides strong adhesion between the coating and the base material. Adhesion tests ensure the metal coating remains intact under mechanical stress.

Hardness: The hardness of the electroplated coating depends on the material used, with certain metals (e.g., gold, nickel) providing excellent surface hardness (up to 600 Vickers).

Corrosion Resistance: Electroplated layers offer substantial protection against environmental factors like moisture and chemicals, with salt spray testing (ASTM B117) commonly used to evaluate corrosion resistance.

Surface Finish: Electroplated coatings provide a smooth and reflective surface, with Ra (roughness) values typically less than 0.5 μm for a glossy finish.

Electroplating Process Flow and Key Parameter Control

The electroplating process consists of several stages, each critical to ensuring a high-quality finish:

Surface Preparation – The 3D printed part must be cleaned before electroplating to remove any dirt, oils, or oxidation. This is typically achieved through ultrasonic, abrasive, or acid treatment.

Plating Bath Preparation – The part is immersed in an electrolyte bath containing the metal salts required for plating, such as nickel, chrome, or gold. The bath’s temperature, pH, and chemical composition are carefully controlled.

Electroplating – An electric current is passed through the electrolyte, causing the metal ions to bond with the surface of the 3D printed part. The plating thickness is controlled by adjusting current density, bath composition, and plating time.

Post-Plating Treatment – After electroplating, the part may undergo rinsing, polishing, or heat treatment to improve adhesion, smoothness, or strength.

Inspection and Testing – The electroplated part is subjected to quality checks, including thickness measurement, adhesion testing, and visual inspection to ensure the coating meets the required standards.

Key parameters that need to be controlled during electroplating include the current density (measured in amps per square meter), plating time (ranging from minutes to hours), temperature (usually between 30-50°C), and bath composition (pH and concentration of metal ions). Careful control of these factors ensures a uniform, durable, high-quality coating.

Applicable Materials and Scenarios

Electroplating is highly effective for various materials used in 3D printing, particularly metals and alloys. Below is a table listing commonly electroplated materials for 3D printed parts and their primary applications, with hyperlinks to the specific materials:

Material | Common Alloys | Applications | Industries |

|---|---|---|---|

Automotive components, medical devices | Automotive, Medical, Aerospace | ||

Aerospace components, medical implants | Aerospace, Medical | ||

Custom automotive parts, aerospace components | Aerospace, Automotive | ||

Electrical connectors, heat exchangers | Electronics, Automotive, Energy |

Electroplating is especially useful for 3D printed parts that need to resist wear, corrosion, and extreme environmental conditions. It is commonly used in aerospace, automotive, and electronics industries, where parts are exposed to high mechanical stress, chemicals, or extreme temperatures.

Advantages and Limitations of Electroplating for 3D Printed Parts

Advantages: Electroplating offers numerous benefits for 3D printed parts:

Enhanced Durability: Electroplated coatings increase the hardness and wear resistance of 3D printed parts, making them ideal for high-stress applications.

Improved Corrosion Resistance: Electroplating offers superior protection against corrosion, making it ideal for parts exposed to moisture, chemicals, and high temperatures.

Aesthetic Appeal: Electroplated coatings provide a shiny, metallic finish that enhances the visual appeal of parts, making them more attractive for consumer products.

Customization: The process allows for a wide range of coatings, such as nickel, chrome, or gold, providing flexibility in both functional and aesthetic properties.

Limitations However, electroplating has some limitations:

Coating Thickness: The coating is typically thin, which may not protect parts exposed to extreme abrasion or impact.

Cost: The electroplating process can be expensive, particularly for high-performance coatings or specialized materials.

Surface Imperfections: The electroplating process can highlight any surface imperfections in the 3D printed part, requiring thorough pre-treatment to achieve a smooth finish.

Electroplating vs. Other Surface Treatment Processes for 3D Printed Parts

Electroplating is often compared to surface treatment processes like anodizing, powder, and PVD. Below is a table comparing electroplating with these processes based on specific parameters:

Surface Treatment | Description | Roughness | Hardness | Wear Resistance | Corrosion Resistance | Aesthetic Appeal |

|---|---|---|---|---|---|---|

Electrochemical process that deposits metal onto the surface | Smooth, Ra < 0.5 μm | High (up to 600 Vickers) | Excellent, particularly for parts exposed to abrasion | Excellent, especially for chemical exposure | Excellent, with a metallic finish | |

Electrochemical process that forms a protective oxide layer | Smooth, Ra < 0.5 μm | Can reach up to 500 Vickers (HV) | Excellent in corrosion resistance | Excellent, especially in saltwater environments | Limited aesthetic options | |

Electrostatic application of powdered coating for durability | Smooth to slightly rough, Ra 1-3 μm | Moderate (typically 200-300 Vickers) | Excellent, especially for outdoor parts | Good, but not as durable as anodizing | Good for larger parts | |

Thin coatings applied through physical vapor deposition | Ultra-smooth, Ra < 0.1 μm | High (typically 900-1200 Vickers) | Very high, especially in dry conditions | Very good, excellent against high-temperature oxidation | Excellent, with a high aesthetic quality |

Application Cases for Electroplated 3D Printed Parts

Electroplating is used across various industries to improve the performance and appearance of 3D printed parts. Some notable application cases include:

Aerospace: Electroplated components, such as turbine blades, show up to a 40% improvement in corrosion resistance under high-temperature conditions.

Automotive: Electroplated exhaust system parts improve durability by 50%, enhancing resistance to heat and chemicals.

Electronics: Electroplated connectors and contacts ensure reliable performance, with a 25% reduction in wear and corrosion.

Medical: Medical implants with electroplated coatings show improved biocompatibility and resistance to wear, ensuring longer implant life.

FAQs

How does electroplating improve the durability of 3D printed parts?

What types of materials are commonly electroplated in 3D printing?

How does electroplating compare to other surface treatments like anodizing or powder coating?

What are the common metals used for electroplating in 3D printing?

How long does the electroplating process take for 3D printed parts?