Precision Titanium 3D Printing: Complex Geometries with Superior Strength Medical Implants

Introduction

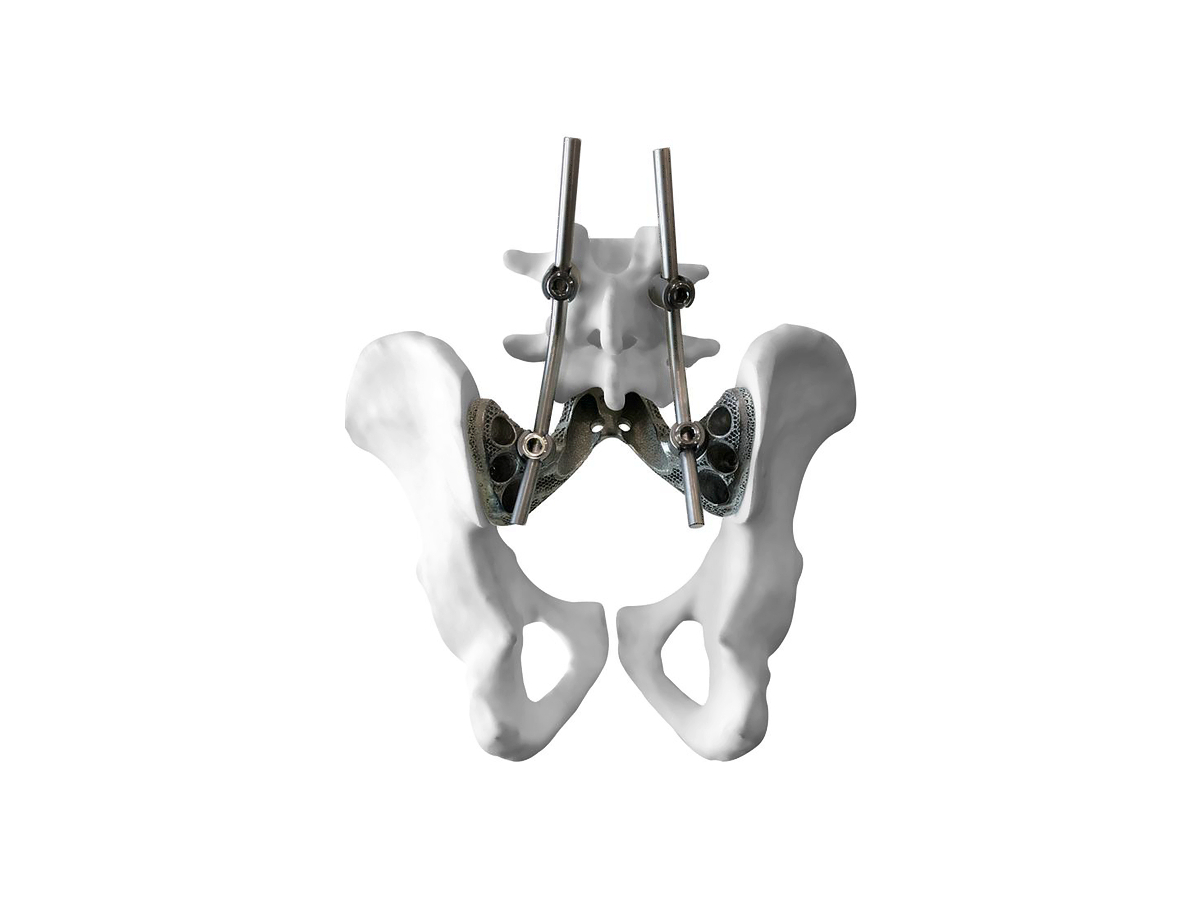

Precision titanium 3D printing has revolutionized the manufacturing of complex, patient-specific medical implants. Utilizing advanced additive manufacturing technologies like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), high-performance titanium alloys such as Ti-6Al-4V ELI (Grade 23) ensure implants achieve exceptional strength, biocompatibility, and longevity.

Compared to traditional machining and casting, precision titanium 3D printing enables the fabrication of intricate lattice structures, customized anatomies, and optimized stress-distribution designs, accelerating recovery and improving clinical outcomes.

Applicable Material Matrix

Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Biocompatibility |

|---|---|---|---|---|---|

4.43 | 900 | 830 | 10% | Excellent | |

4.52 | 950 | 880 | 12% | Excellent | |

4.51 | 344 | 275 | 20% | Excellent | |

4.43 | 950 | 880 | 14% | Very Good | |

4.65 | 980 | 930 | 12% | Good | |

4.46 | 860 | 795 | 18% | Good |

Material Selection Guide

Ti-6Al-4V ELI (Grade 23): Standard for orthopedic implants such as hip stems and spinal cages due to excellent fatigue strength and biocompatibility.

Ti-6Al-7Nb: Suitable for dental implants and bone fixation devices requiring superior mechanical strength and enhanced biological integration.

CP-Ti Grade 2: Ideal for cranial plates and dental frameworks needing high corrosion resistance and ductility.

Ti-6Al-4V (Grade 5): Used for high-load medical components where superior mechanical strength and moderate biocompatibility are needed.

Ti-6Al-2Sn-4Zr-2Mo: Best for implants requiring exceptional tensile strength and resistance to mechanical stress, such as trauma plates.

Ti-5Al-2.5Sn (Grade 6): Applied in specialized prosthetics where moderate strength and high ductility are critical.

Process Performance Matrix

Attribute | Titanium 3D Printing Performance |

|---|---|

Dimensional Accuracy | ±0.03 mm |

Density | >99.8% |

Layer Thickness | 20–40 μm |

Surface Roughness | Ra 5–10 μm |

Minimum Feature Size | 0.2 mm |

Process Selection Guide

Complex Geometries: Enables the production of lattice structures that promote bone in-growth and reduce implant weight.

High Strength and Durability: Achieves tensile strengths up to 950 MPa, crucial for load-bearing orthopedic applications.

Superior Biocompatibility: Titanium’s inert nature minimizes the risk of adverse reactions, ensuring patient safety.

Customized Fit: Patient-specific implants are created directly from medical imaging data, improving surgical precision and healing outcomes.

Case In-Depth Analysis: Customized Ti-6Al-4V ELI Cranial Implant

A medical center required a patient-specific cranial plate with complex curvature and porous structures to promote tissue integration. Using our precision titanium 3D printing service with Ti-6Al-4V ELI, we manufactured an implant achieving density >99.8%, tensile strength of 900 MPa, and dimensional accuracy within ±0.03 mm. The porous lattice design reduced the implant weight by 30% and significantly accelerated bone regrowth. Post-processing included fine CNC machining for critical interfaces and electropolishing to enhance surface smoothness and biocompatibility.

Industry Applications

Orthopedics

Custom hip and knee prostheses with porous structures.

Spinal cages, plates, and fixation screws.

Trauma implants for fracture repair.

Dental and Maxillofacial

Patient-specific dental implants and abutments.

Customized jawbone and cranial implants.

Oral-maxillofacial reconstructive components.

Cardiovascular and Biomedical Devices

Customized titanium stents.

Valve frames and vascular graft supports.

Lightweight, durable implantable device components.

Mainstream 3D Printing Technology Types for Titanium Medical Implants

Selective Laser Melting (SLM): Best suited for intricate, high-density medical implants requiring tight tolerances.

Electron Beam Melting (EBM): Ideal for load-bearing implants with excellent mechanical properties and minimal residual stress.

Direct Metal Laser Sintering (DMLS): Optimal for detailed, small-to-medium size implant production.

Binder Jetting: Useful for rapid prototyping of initial implant designs and early-stage device development.

Laser Metal Deposition (LMD): Suitable for adding features or repairing high-value medical components.

FAQs

What titanium alloys are most suitable for 3D printed medical implants?

How does 3D printing improve implant design compared to traditional manufacturing?

What post-processing steps are required for titanium medical implants?

How is patient-specific data used to manufacture customized titanium implants?

What are the main advantages of using precision titanium 3D printing in orthopedic applications?