What challenges exist when 3D printing stainless steel, and how can they be addressed?

What Challenges Exist When 3D Printing Stainless Steel, and How Can They Be Addressed?

1. Residual Stress and Warping

Challenge: Rapid heating and cooling cycles in processes like Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS) generate high thermal gradients, leading to residual stresses that can cause part distortion, warping, or cracking—especially in large or thin-walled components.

Solution: Apply optimized scan strategies, support structures, and controlled cooling. Post-process with heat treatment and Hot Isostatic Pressing (HIP) to relieve stress and enhance dimensional stability.

2. Porosity and Incomplete Fusion

Challenge: Insufficient laser energy or inconsistent powder deposition may cause porosity or lack-of-fusion defects in stainless steel parts, reducing mechanical strength and fatigue resistance.

Solution: Use high-quality stainless powders like SUS316L or SUS17-4PH, and optimize process parameters (laser power, hatch spacing, layer thickness). Apply HIP to eliminate internal voids and improve density.

3. Surface Roughness and Post-Processing Requirements

Challenge: As-printed stainless steel surfaces often exhibit Ra values >10 µm, which can negatively impact fatigue life, sealing interfaces, or appearance in medical or consumer electronics applications.

Solution: Use finishing methods such as CNC machining, polishing, electropolishing, or PVD coating to meet functional and cosmetic requirements.

4. Powder Handling and Oxidation Risk

Challenge: Stainless steel powders are sensitive to contamination and moisture, which can degrade flowability and cause inconsistent melting or oxidation during printing.

Solution: Store and handle powders in inert atmospheres. Use closed-loop powder systems with controlled humidity and oxygen levels. Recycle powder using proper sieving protocols to maintain consistency and print quality.

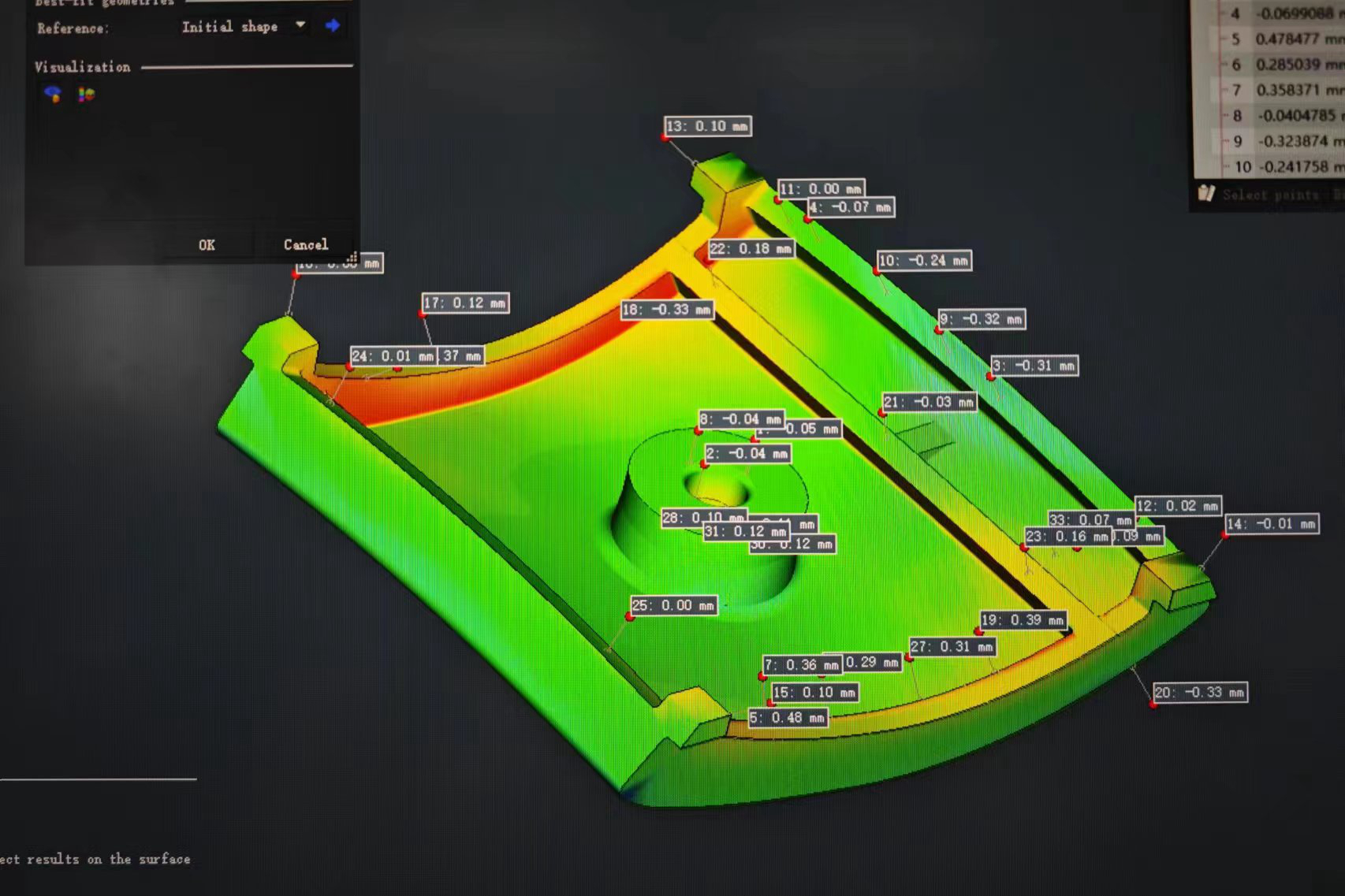

5. Shrinkage and Dimensional Accuracy

Challenge: Thermal contraction during printing and post-processing may cause dimensional deviations, especially in dense geometries or unsupported structures.

Solution: Apply design compensation and simulation-based distortion prediction. Use stress-relief heat treatments and controlled build orientation to minimize unsupported overhangs and thermal distortion.

Recommended Services to Address Stainless Steel Printing Challenges

Neway offers integrated services for resolving key stainless steel 3D printing issues:

Stainless Steel 3D Printing: For structural, corrosion-resistant parts

CNC Machining: For surface and dimensional precision

Heat Treatment: For microstructure control and stress relief

HIP: For porosity elimination and fatigue improvement

Surface Treatment: For corrosion resistance and cosmetic finishing