Which 3D printing technology is best for stainless steel parts in aerospace applications?

Which 3D Printing Technology Is Best for Stainless Steel Parts in Aerospace Applications?

Optimal Technology: Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is the most suitable 3D printing technology for producing stainless steel parts in aerospace applications. SLM provides excellent precision, part density exceeding 99.5%, and mechanical properties that meet the high-strength, fatigue, and thermal stability requirements demanded in aerospace environments. It uses a high-energy laser to fully melt stainless steel powders layer by layer, resulting in parts with material performance comparable to wrought alloys.

Common Stainless Steel Grades for Aerospace

SUS316L

Offers excellent corrosion resistance, good ductility, and weldability. Commonly used in fluid handling components, structural brackets, and vibration-resistant assemblies.

SUS630 / 17-4 PH

A precipitation-hardened stainless steel with high strength and moderate corrosion resistance. Ideal for high-load aerospace components such as mounting blocks, housings, and actuator supports.

SUS15-5 PH

Provides enhanced toughness over 17-4 PH with equivalent strength. Used in structural frames and precision mechanical subassemblies.

Advantages of SLM for Aerospace Stainless Steel Parts

Near-net shape fabrication of complex geometries, including internal channels and lattice structures

Excellent fatigue performance and isotropic strength

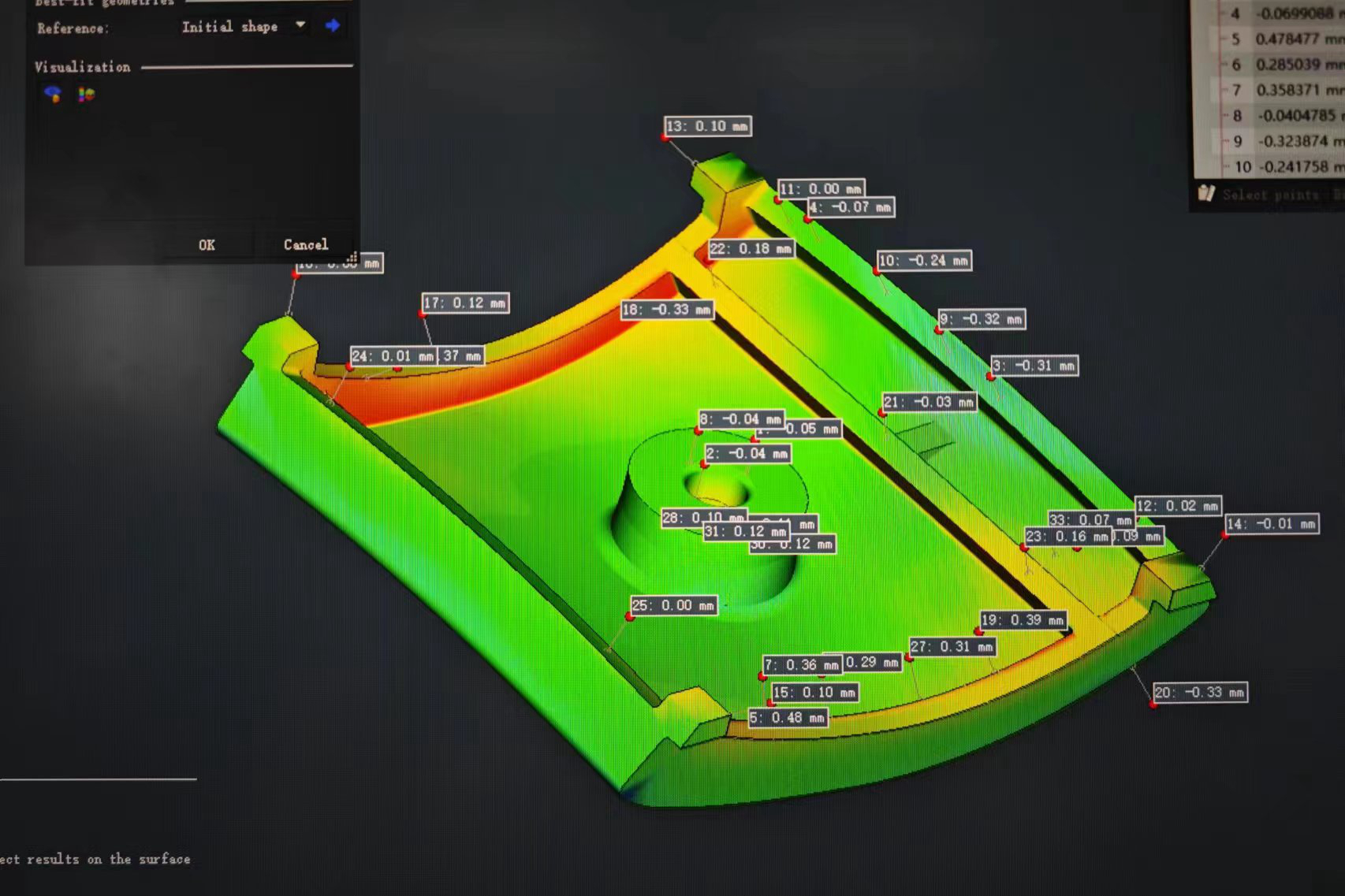

High dimensional accuracy with typical tolerances of ±0.1 mm

Compatibility with post-processing like heat treatment and hot isostatic pressing (HIP) for further optimization

Customer-Oriented Solutions and Services

To support aerospace stainless steel applications, we offer:

3D Printing Technologies:

Leverage our Stainless Steel 3D Printing capabilities built on Selective Laser Melting (SLM) for high-precision, aerospace-grade production.

Aerospace-Grade Materials:

Choose from our full range of stainless steels, including SUS316L, SUS630, SUS15-5 PH, and SUS304L for corrosion-sensitive environments.

Industry-Specific Services:

Explore our aerospace and aviation solutions, supported by CNC machining, heat treatment, and surface treatment to meet aerospace certification standards.